Leave Your Message

As the need for enhanced safety measures in gas systems becomes increasingly critical, the role of Flame Arrestors has gained significant attention. Flame Arrestors are essential devices designed to prevent the propagation of flames into safe areas, thereby protecting both people and property. According to a recent industry report published by the International Gas Association, more than 40% of industrial accidents involving flammable gases could have been mitigated through the effective use of Flame Arrestor technology. This highlights the urgent necessity for comprehensive understanding and implementation of these systems in various applications.

Dr. Emily Carter, a leading expert in flame suppression technologies, emphasizes the importance of this safety measure: "The integration of Flame Arrestors in gas systems not only enhances safety but also assures compliance with stringent industry regulations." As industries move towards more rigorous safety standards, the demand for innovative and reliable Flame Arrestor solutions is expected to rise. This guide will explore the top Flame Arrestor solutions available in 2025, offering insights into their designs, applications, and the safety standards they meet, ensuring sustained safety and operational efficiency in hazardous environments.

Flame arrestors are critical safety devices designed to prevent the propagation of flames through gas systems. They function by dissipating the energy of a flame front, allowing for the safe venting of flammable gases while effectively stopping fire from traveling back into networks where it could cause devastating explosions. By trapping flames and creating barriers between potential ignition sources and flammable materials, flame arrestors play a vital role in protecting equipment and personnel in various industrial applications.

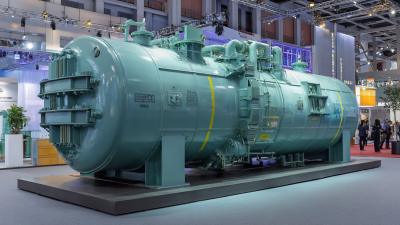

Moreover, the importance of flame arrestors cannot be overstated, especially in sectors dealing with volatile substances. These devices are strategically deployed in pipelines, storage tanks, and processing units to enhance overall safety. Their ability to allow for the safe operation of gas systems reduces the risk of catastrophic events, safeguarding both the environment and human lives. Furthermore, regular maintenance and proper installation of flame arrestors are essential to ensure they function effectively, reinforcing their status as an indispensable component in the infrastructure of gas systems.

Flame arrestors are essential safety devices used in gas systems to prevent the propagation of flames while allowing the passage of gases. These devices are designed with specific types that cater to different applications, focusing on their design and functionality to ensure optimal safety. The primary types of flame arrestors include active, passive, and thermal flame arrestors.

Active flame arrestors utilize a sophisticated mechanism that detects rising temperatures and extinguishes flames, while passive flame arrestors depend on physical barriers to obstruct flame paths. Thermal flame arrestors, on the other hand, employ heat-absorbing materials to mitigate the heat generated by flames.

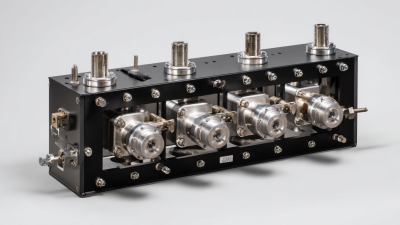

The design of flame arrestors typically includes a series of perforated plates or mesh screens, which serve to cool and disperse the energy of a potentially dangerous flame front. The effectiveness of these devices revolves around their ability to withstand high pressures and maintain structural integrity under extreme conditions.

Each type is tailored for specific applications, ensuring that a flame arrestor functions optimally within the parameters of its environment. Understanding the properties and operational principles of these devices is crucial for the safety of gas systems, making them a vital component in industry practices where flammable gases are present.

When selecting a flame arrestor for gas systems, there are several critical factors to consider to ensure both safety and efficiency. The first aspect is the type of gas being used. Different gases require varying levels of protection and specific arrestor designs to manage the unique risks associated with their combustion properties. Understanding the gas characteristics, such as its ignition energy, flammability range, and temperature limits, will guide you in choosing the right flame arrestor that can withstand potential hazards.

Another significant factor to consider is the pressure drop across the arrestor. A well-designed flame arrestor should minimize pressure loss to maintain system efficiency while providing adequate protection against flames. It is vital to evaluate the flow rates and expected operating conditions, as these will influence the selection of the arrestor type and model.

**Tips:** Always consult with industry experts or professionals when assessing specific applications and requirements for flame arrestors. Regular maintenance and inspections should also be scheduled to ensure the devices remain effective over time. Additionally, familiarize yourself with relevant safety standards that apply to your industry to ensure compliance and optimal safety practices.

When it comes to ensuring safety and efficiency in gas systems, proper installation of flame arrestors plays a crucial role. According to a report from the National Fire Protection Association (NFPA), improper installation can lead to catastrophic failures, which are responsible for 60% of incidents in industrial settings. Therefore, adhering to best practices during installation not only protects personnel and assets but also enhances the overall performance of gas systems.

To maximize safety and efficiency, it is essential to position flame arrestors at appropriate locations within the gas piping system. Industry standards recommend assessing the flow dynamics and potential ignition sources before installation. Additionally, ensuring that the flame arrestor is matched to the specific application and gas type is critical; mismatched components can lead to decreased efficacy. Regular maintenance checks, as highlighted in the American Petroleum Institute (API) guidelines, further ensure that these systems remain operational and effective throughout their service life. By following these best practices, organizations can significantly mitigate risks and enhance operational efficiency.

| Flame Arrestor Type | Application | Material | Max Operating Pressure (psi) | Temperature Range (°F) | Typical Installation Location |

|---|---|---|---|---|---|

| End-of-Line Flame Arrestor | Storage Tanks | Stainless Steel | 150 | -40 to 150 | Aboveground Tanks |

| In-Line Flame Arrestor | Pipelines | Aluminum | 200 | -20 to 180 | Gas Transport Lines |

| Combination Flame Arrestor | Process Vessels | Carbon Steel | 250 | -40 to 250 | Industrial Facilities |

| Portable Flame Arrestor | Field Applications | Composite Materials | 100 | -20 to 120 | On-Site Operations |

Regular maintenance and inspection of flame arrestors are crucial for ensuring optimal performance in gas systems. A well-implemented maintenance schedule should include checking for blockages, corrosion, and wear that could compromise the unit's integrity. It’s essential to follow the manufacturer's guidelines for disassembly and inspection processes, as improper handling can lead to damage and increased risk of failure. Personnel should be trained to recognize signs of wear or malfunction, including changes in gas flow or unusual noises, which may indicate that maintenance is required.

Inspection procedures should involve a systematic approach to checking all components of the flame arrestor. This includes examining the mesh or baffle structures for any signs of accumulation or damage, as these elements are key to preventing flame propagation. Visual inspections should be complemented with functional tests to ensure that the device operates within specified parameters. Regular documentation of inspection results and any maintenance activities will help in tracking performance over time and identifying any recurring issues that may need addressing. Ultimately, a proactive approach to maintenance and inspection will contribute to the longevity and reliability of flame arrestors in gas systems, bolstering overall safety.