Leave Your Message

In an ever-evolving industrial landscape, safety remains the utmost priority, especially in environments dealing with flammable gases and vapors. One of the essential components in mitigating fire risks is the Inline Flame Arrestor, a device designed to prevent the propagation of flames within piping systems. As industries continue to advance and adopt new technologies, understanding the key features and benefits of the top Inline Flame Arrestors available in 2025 becomes crucial for ensuring operational safety and compliance.

Inline Flame Arrestors play a vital role in protecting equipment and personnel by acting as barriers that extinguish flames before they can travel through pipes. The effectiveness of these devices is influenced by factors such as their construction materials, design, and installation practices. In this article, we will delve into the various types of Inline Flame Arrestors, highlighting their critical features and the advantages they offer across different applications. By doing so, we aim to provide a comprehensive understanding that assists in making informed decisions when selecting the right flame arrestor for specific industrial needs.

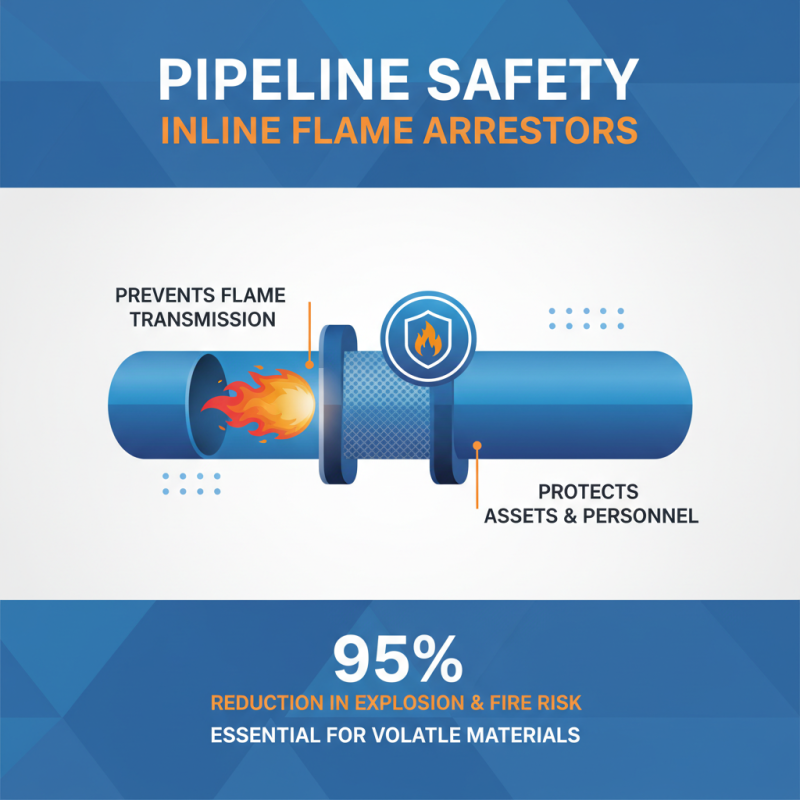

Inline flame arrestors play a crucial role in various industrial applications by preventing the propagation of flame through piping systems. These devices are strategically installed to mitigate the risks associated with flammable gases and vapors. Their primary function is to extinguish flames that may travel back towards the source of ignition, thereby protecting equipment and personnel from potential explosions and fires. In industries such as oil and gas, chemical processing, and wastewater treatment, flame arrestors are essential components that enhance safety protocols and ensure operational integrity.

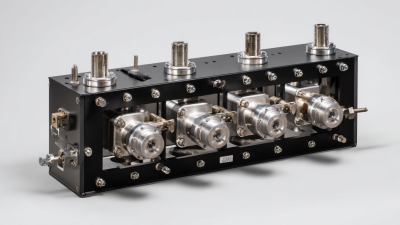

When selecting an inline flame arrestor, it is essential to consider key features such as the material construction, size, and pressure drop characteristics. For instance, materials like stainless steel or aluminum are often preferred for their durability and resistance to corrosive environments. It's also important to ensure that the arrestor is appropriately sized for the piping system to maintain efficiency while preventing undue pressure loss.

Tips: Regular maintenance and inspection of flame arrestors can significantly prolong their life and effectiveness. It's advisable to incorporate them into routine safety audits to identify any signs of wear or damage. Additionally, understanding the specific requirements of your application can aid in selecting the right flame arrestor, ensuring optimal performance and safety.

Inline flame arrestors are critical safety devices designed to prevent the propagation of flames in piping systems, effectively protecting equipment and personnel from catastrophic incidents. Their operation hinges on a simple yet effective mechanism that utilizes a series of carefully designed passages and cooling elements. When a flame approaches the arrestor, the constricted flow channels dissipate heat, cooling the gases as they pass through. A report by the National Fire Protection Association highlights that the implementation of inline flame arrestors in industrial settings can reduce the risk of explosions by up to 60%, underscoring their importance in safety protocols.

The design of these devices is rooted in specific engineering principles that ensure their effectiveness. Each unit must meet stringent standards regarding the materials used and their thermal resistance capabilities. According to a study published in the Journal of Hazardous Materials, the optimal performance of inline flame arrestors is linked to their ability to withstand significant pressure differentials and high-temperature environments, attributes that are essential in industries such as petrochemical production and pharmaceuticals. Furthermore, regular maintenance is crucial, as a report by the American Institute of Chemical Engineers indicates that failure to inspect arrestors can lead to a 30% increase in operational hazards over time. With proper design, installation, and maintenance, inline flame arrestors remain indispensable components in industrial safety systems.

Inline flame arrestors are essential safety devices designed to prevent flames from traveling along pipelines in various industrial applications. There are several major types of inline flame arrestors—each with unique characteristics tailored for specific environments. The two primary classifications are passive and active flame arrestors.

Passive flame arrestors, often designed as a simple barrier made from a metal mesh or screen, function by cooling and quenching the flames as they attempt to propagate. These devices are ideal for less volatile gas systems where the risk of flame transmission is lower. On the other hand, active flame arrestors utilize more complex mechanisms, often incorporating cooling elements or specialized materials to extinguish flames effectively. They are particularly necessary in high-risk settings where flammable gases are frequently handled.

Another important category includes deflagration and detonation arrestors. Deflagration arrestors are used to stop low-speed flames, making them suitable for most gas pipelines. In contrast, detonation arrestors are engineered to withstand high-speed shockwaves, crucial for scenarios where explosive mixtures may be present. Understanding the different types and their specific uses is critical for selecting the most appropriate inline flame arrestor to ensure maximum safety and compliance in industrial operations.

The installation of inline flame arrestors in pipeline systems plays a critical role in enhancing safety and operational efficiency. These devices serve as passive fire prevention mechanisms, designed to stop the transmission of a flame through the pipeline, thus protecting various assets and personnel from the potential hazards of flammable substances. According to industry reports, utilizing inline flame arrestors can reduce the risk of explosions and fires in industrial operations by up to 95%, providing an essential layer of protection for facilities handling volatile materials.

Moreover, inline flame arrestors contribute significantly to compliance with safety regulations in many sectors, including oil and gas, petrochemicals, and pharmaceuticals. The Global Fire Protection Equipment Market is projected to reach $100 billion by 2026, emphasizing the increasing priority given to safety measures. Moreover, these devices can enhance system efficiency by maintaining pressure and flow rates, which means that organizations can not only ensure safety but also improve their operational performance. The investment in flame arrestors yields long-term benefits, illustrating their importance in a reliable and safe pipeline infrastructure.

When selecting an inline flame arrestor, several critical factors must be considered to ensure optimal performance and safety. The first aspect is the operating environment, including the temperatures and pressures that the device will experience. It's essential to choose an arrestor that can withstand the necessary conditions, as this will directly impact its effectiveness in preventing flame propagation. Materials used in construction should also be assessed; for instance, corrosion-resistant options are preferable in chemical applications or environments exposed to moisture.

Another important consideration is the flow rate and the size of the flame arrestor. The device must be appropriately sized to handle the maximum flow expected without causing a significant pressure drop in the system. This requires a balance between the size of the arrestor and the required performance parameters. Additionally, understanding the specific application and the type of fuel can guide users in selecting the right design, whether it’s a passive or active flame arrestor, ensuring optimal safety and efficiency in gas or vapor transport systems.