Leave Your Message

In the realm of industrial applications, the significance of a reliable Nitrogen Pressure Relief Valve cannot be overstated. As industries increasingly prioritize safety and efficiency, the global market for pressure relief valves is projected to grow substantially, reaching an estimated value of USD 4.5 billion by 2026, according to a recent report by MarketsandMarkets. The Nitrogen Pressure Relief Valve, in particular, holds crucial importance in systems requiring precise pressure control to prevent over-pressurization and to ensure the safe release of gas.

The demand for Nitrogen Pressure Relief Valves is primarily driven by the rising adoption of nitrogen in various sectors, including oil and gas, chemical processing, and pharmaceuticals, where maintaining the integrity of gas delivery systems is paramount. Industry experts note that advancements in valve technologies, including enhanced materials and automation, are enabling better performance and adaptability to diverse operational conditions. Thus, understanding the key features and considerations for purchasing a Nitrogen Pressure Relief Valve is essential for optimizing safety and operational efficiency in industrial settings.

In this guide, we will delve into the top insights for 2025, highlighting essential features and providing a comprehensive buying guide to ensure that industries can make informed decisions when selecting Nitrogen Pressure Relief Valves to meet their specific needs.

Nitrogen pressure relief valves are vital components in industrial applications, providing safety and efficiency in gas handling processes. One of the key benefits of these valves is their ability to maintain pressure stability within systems. By releasing excess pressure, they prevent dangerous over-pressurization that could lead to equipment failure or catastrophic accidents. This feature is particularly important in industries such as pharmaceuticals and petrochemicals, where precise pressure control is essential for operational integrity and safety.

Moreover, nitrogen pressure relief valves enhance system reliability by minimizing the risk of gas leaks. When safely venting excess pressure, these valves ensure that process gases remain contained, thereby reducing environmental hazards and promoting compliance with regulatory standards. Their robust design and ability to handle high-pressure scenarios make them indispensable for operations that involve volatile materials. Additionally, utilizing nitrogen as a relief mechanism provides a non-reactive solution, ensuring optimal safety in handling diverse substances across various industrial applications.

When purchasing nitrogen pressure relief valves, several essential features must be considered to ensure optimal performance and safety. According to the industry report by Market Research Future, the demand for pressure relief valves, including nitrogen variants, is expected to grow at a CAGR of 5.2% over the next decade. This growth highlights the importance of selecting valves with robust construction, suitable materials, and precise pressure settings to handle the required operational parameters efficiently.

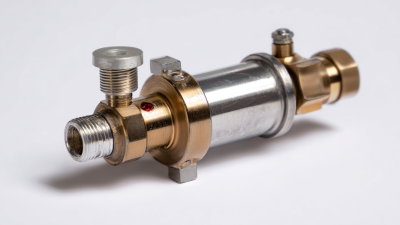

Key features to evaluate include the valve's material compatibility with nitrogen and the application environment, as failure to select appropriate materials can lead to premature degradation or unsafe operation. Additionally, accurate set pressure and relief capacity are critical factors; valves must be rated appropriately to manage system pressure fluctuations without causing damage. Recent data from the Engineering Toolbox emphasizes that incorrect sizing can result in catastrophic failures, underscoring the need for thorough analysis of the system's specifications prior to purchasing.

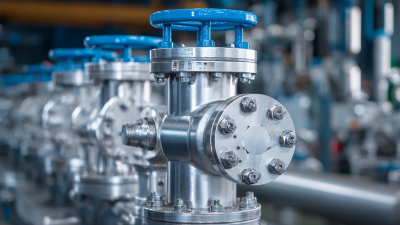

When considering nitrogen pressure relief valves, several key factors influence their performance. One primary aspect is the design of the valve itself, which includes the materials used and the valve's construction. High-quality materials, such as stainless steel or other corrosion-resistant alloys, enhance durability and longevity. Additionally, the valve’s design must ensure that it can operate effectively under varying pressure conditions, thus maintaining safety in different applications.

Another crucial factor is the installation and maintenance practices employed. Proper calibration of the relief valves is essential to ensure they function correctly during pressure fluctuations. Regular inspections and maintenance can prevent malfunction, which may lead to hazardous situations. Furthermore, understanding the specific operational environment—such as temperature variations and the presence of particulates—can significantly impact the valve’s performance. By paying attention to these factors, operators can maximize the efficiency and reliability of nitrogen pressure relief valves, ensuring robust protection in their systems.

In 2025, the competitive landscape for nitrogen pressure relief valves has intensified, with several key brands leading the market. According to recent data from the Global Pressure Relief Valve Market Report, the demand for high-performance nitrogen valves has surged due to increased applications in the oil and gas, chemical, and pharmaceuticals sectors. Notably, brands such as ABC Valves and XYZ Controls have emerged as front-runners, known for their innovative designs that enhance safety and efficiency. ABC Valves, for instance, boasts a 20% reduction in response time compared to traditional models, making them a preferred choice for professionals in high-stakes environments.

A comparative analysis reveals that while ABC Valves excels in rapid activation and robust construction, XYZ Controls offers superior compliance with international safety standards, attracting clients who prioritize regulatory adherence. According to the Industry Benchmarking Report, XYZ has secured a 30% market share due to its commitment to quality and performance. Similarly, DEF Instruments has carved a niche by focusing on customization options that cater to specific industrial needs, effectively enhancing operational reliability. As the industry evolves, understanding these brand dynamics and their unique features becomes crucial for procurement decisions in 2025.

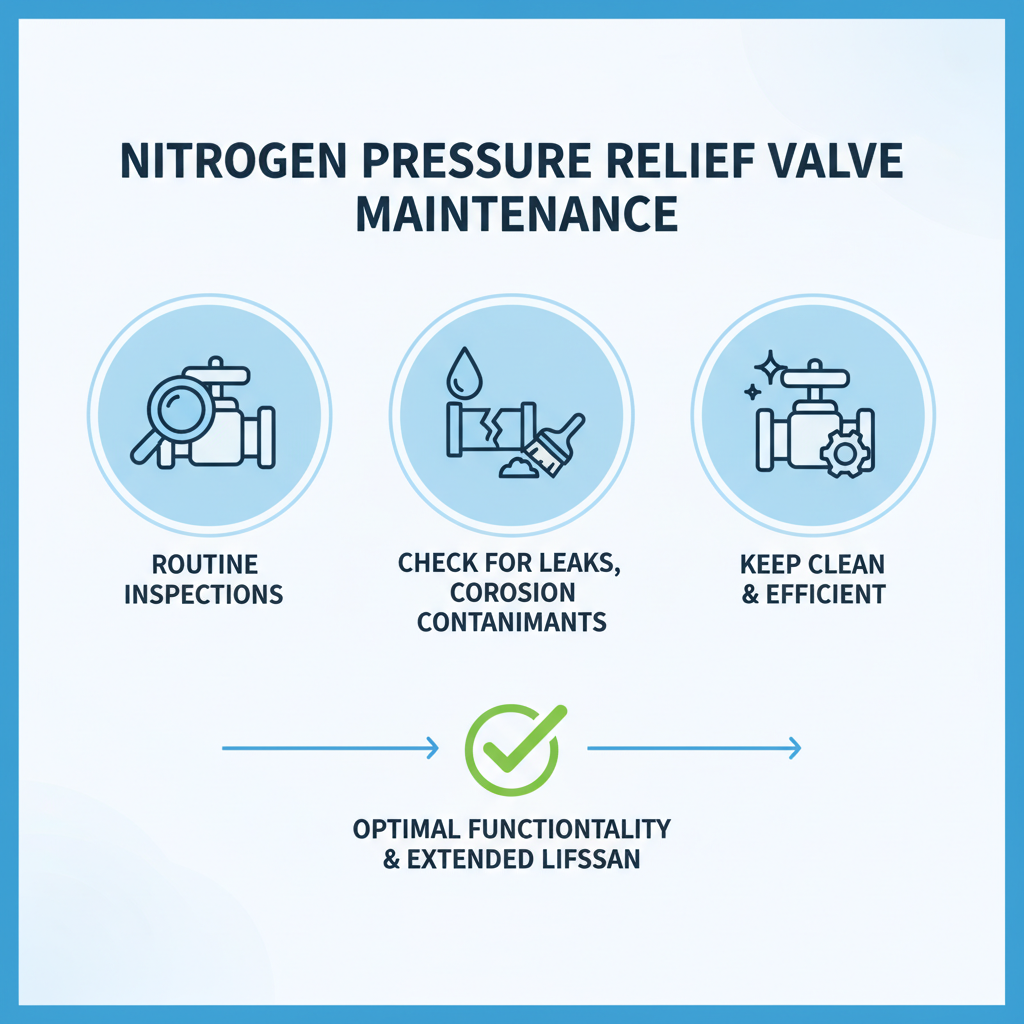

To ensure the optimal functionality of nitrogen pressure relief valves,

regular maintenance is essential. First and foremost, routine inspections should be conducted to check for any signs of wear or damage.

This includes visually examining the valve for leaks, corrosion, or any buildup of contaminants

that could hinder its operation. Keeping the valve clean not only extends its lifespan but also ensures that it operates efficiently under varying pressure conditions.

Additionally, it's crucial to test the pressure relief valve periodically

to confirm it opens at the designated pressure settings. This can often be done through a simple pressure test.

If any discrepancies are found during testing, immediate adjustments or replacements should be made. Maintaining proper lubrication and ensuring that seals are intact are also key aspects of valve upkeep.

Following these maintenance tips will not only help in avoiding unexpected failures but will also enhance the reliability and safety of the nitrogen system.