Leave Your Message

In the evolving landscape of industrial equipment, the Pressure Relief Valve (PRV) stands out as a critical component for ensuring safety and efficiency in various applications. As noted by renowned industry expert Dr. Emily Harrington, "The effectiveness of a Pressure Relief Valve can mean the difference between operational success and catastrophic failure." This statement underscores the integral role these valves play in protecting systems from overpressure, thereby preventing potential hazards that can arise from equipment malfunction.

As we look ahead to the trends and insights shaping the PRV industry in 2025, it is vital to consider not only technological advancements but also the growing emphasis on regulatory compliance and safety protocols. With increasing demands for reliability and performance, manufacturers are innovating to enhance the functionality and longevity of Pressure Relief Valves. The industry is likely to witness a surge in the integration of smart technologies, allowing for real-time monitoring and predictive maintenance, further solidifying the importance of these valves in modern industrial applications.

Understanding these trends will empower stakeholders to make informed decisions that promote safety and operational efficiency. As we delve deeper into the upcoming developments in Pressure Relief Valves, it is essential to stay updated on the latest insights that will shape the future of this indispensable component.

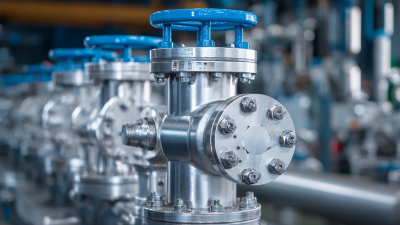

The market for pressure relief valves in 2025 is seeing a significant evolution driven by advancements in technology and increased regulatory requirements. With industries facing a growing emphasis on safety and efficiency, the demand for modern pressure relief valves is on the rise. These valves play a crucial role in preventing overpressure situations, making their reliability essential in sectors like oil and gas, chemical processing, and pharmaceuticals. As industries adapt to stricter safety standards, manufacturers are incorporating innovative materials and smart monitoring technologies to enhance the performance and longevity of their products.

Additionally, the pressure relief valve market is experiencing a shift towards automation and IoT integration. This trend allows for real-time monitoring and predictive maintenance, enabling companies to anticipate issues before they escalate into critical failures. Moreover, the increased focus on sustainability is leading to the development of more energy-efficient valves that minimize waste and reduce environmental impact. As organizations continue to prioritize both operational efficiency and environmental responsibility, the market is likely to attract new players focused on pioneering designs and sustainable practices.

| Region | Market Size (USD Million) | CAGR (%) | Key Trends | Application Areas |

|---|---|---|---|---|

| North America | 600 | 3.5 | Increasing industrial automation and safety regulations | Oil & Gas, Chemical Processing |

| Europe | 500 | 4.2 | Focus on renewable energy systems | Power Generation, Water Treatment |

| Asia-Pacific | 750 | 5.0 | Rapid industrialization and urbanization | Manufacturing, Pharmaceuticals |

| Latin America | 200 | 3.0 | Growing investments in infrastructure | Infrastructure, Mining |

| Middle East & Africa | 300 | 3.8 | Expansion of oil & gas projects | Oil & Gas, Chemical Industry |

The design of pressure relief valves (PRVs) is undergoing significant transformation, driven by technological advancements that prioritize efficiency, safety, and functionality. One of the key innovations shaping this sector is the integration of smart technologies into valve systems. According to the latest market analysis, the pressure relief valve market is projected to grow at a CAGR of 4.8% from 2023 to 2028, largely fueled by these advancements. Smart PRVs equipped with IoT capabilities enable real-time monitoring and remote control, allowing for enhanced operational oversight and proactive maintenance, reducing the risk of failures in industrial processes.

Additionally, the shift towards more environmentally sustainable practices is influencing PRV design. Manufacturers are focusing on developing valves that minimize leakage and enhance energy efficiency. Recent data from industry reports indicate that about 30% of PRV failures are due to improper sealing and design flaws, prompting a concerted effort to improve materials and engineering techniques. Innovations such as using advanced polymers and metals resistant to corrosion and wear are becoming commonplace, ensuring longer service lives and reducing the environmental impact of valve failures. As the industry evolves, continuous research and development will play a critical role in meeting the growing demands for safety and sustainability in pressure relief systems.

The landscape of pressure relief valve applications is undergoing significant transformation due to a series of regulatory changes that aim to enhance safety and operational efficiency. Regulatory bodies are increasingly focusing on the performance and reliability of pressure relief systems to prevent hazardous incidents. This involves stricter guidelines for design, testing, and maintenance practices, which manufacturers and operators must adhere to in order to comply with new safety standards.

Given these changes, it is vital for industry stakeholders to stay informed about emerging regulations and best practices. Companies should invest in training programs that educate personnel on the latest compliance requirements and operational techniques. This ensures that everyone involved is aware of their responsibilities and the implications of non-compliance.

**Tips:** Regularly review regulatory updates and consider partnering with compliance experts to streamline adherence processes. Implementing robust documentation practices can also alleviate the challenges associated with staying aligned with current standards. Moreover, conducting periodic audits of pressure relief systems can help identify potential compliance gaps and areas for improvement, ultimately leading to safer and more efficient operations.

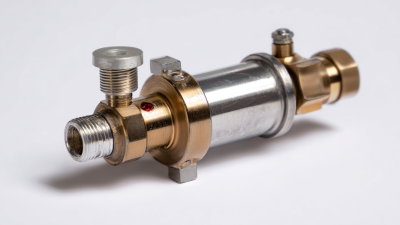

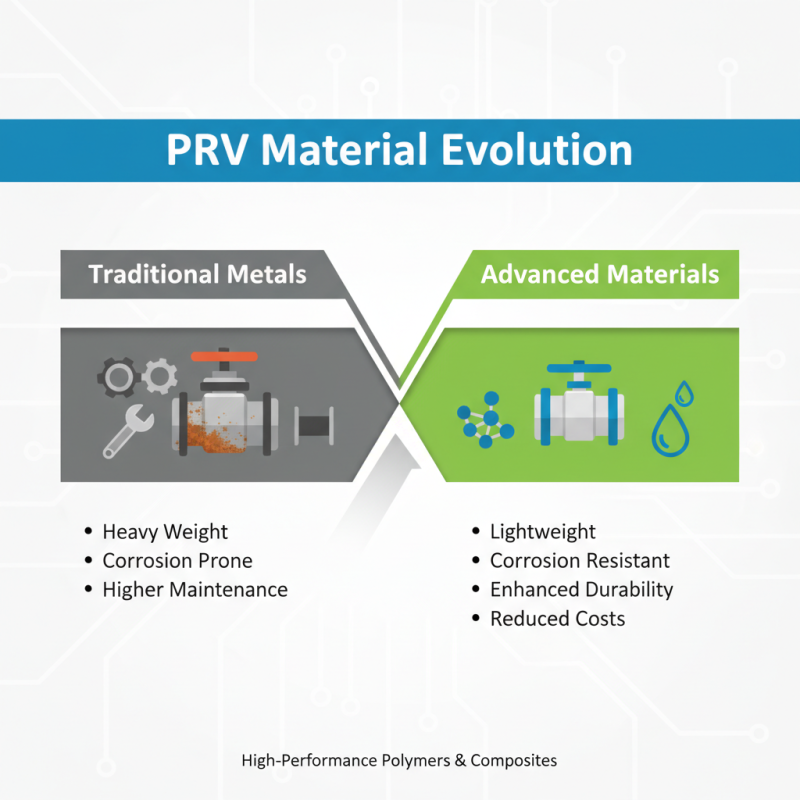

The pressure relief valve (PRV) industry is experiencing a significant shift in material choices, driven by advancements in technology and the growing demand for durability and performance. Emerging materials such as high-performance polymers and composite materials are becoming increasingly popular in the manufacturing of pressure relief valves. These materials offer enhanced corrosion resistance, lighter weight, and improved pressure handling capabilities compared to traditional metals. This shift not only improves the longevity of the valves but also contributes to a reduction in maintenance costs over time.

When selecting materials for pressure relief valves, it is essential to consider the specific application and environmental conditions. For instance, high-performance plastics may be ideal for less corrosive environments, while metal alloys might be necessary for extreme pressure and temperature conditions.

**Tips:** Always assess the compatibility of materials with the fluids they will come into contact with. This can help prevent premature failure and ensure optimal performance. Additionally, keep an eye on emerging materials and technologies; they can provide innovative solutions that improve efficiency and reliability in your systems. Investing in research about material advancements will not only keep you ahead of the curve but also enhance the safety and effectiveness of your operations.

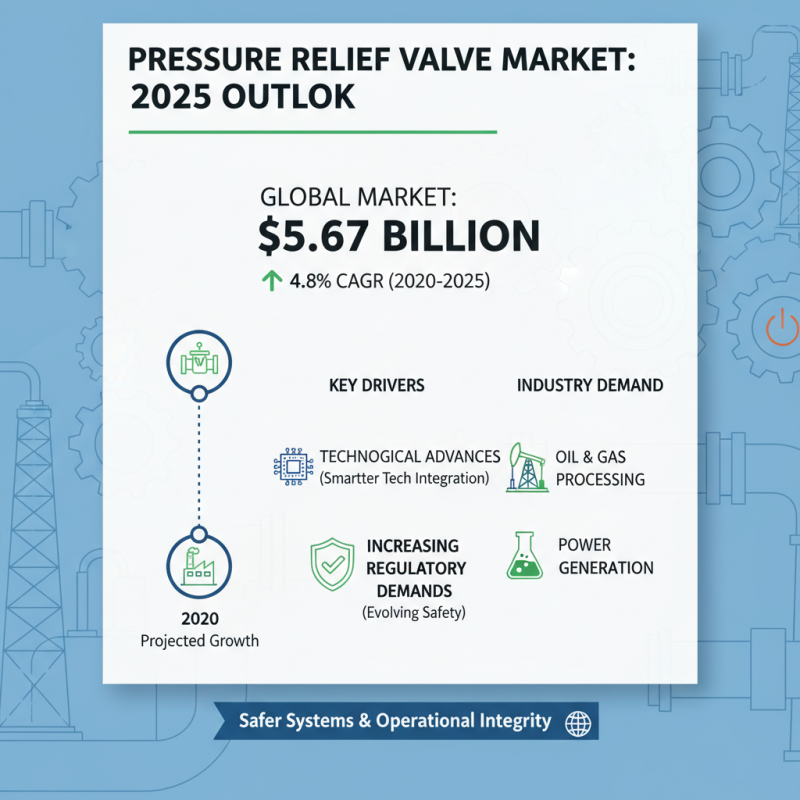

The manufacturing landscape for pressure relief valves is set to undergo significant transformations by 2025, driven by both technological advances and increasing regulatory demands. According to a recent market study, the global pressure relief valve market is expected to reach $5.67 billion by 2025, exhibiting a compound annual growth rate (CAGR) of 4.8% from 2020. This growth can be attributed to the need for safer systems in industries such as oil and gas, chemical processing, and power generation, where the operational integrity of pressure relief valves is paramount. As manufacturers prepare to meet this rising demand, they face the challenge of integrating smarter technologies while adhering to evolving safety regulations.

Anticipating future challenges in the manufacturing process, companies must emphasize innovation in design and materials. Reports indicate that the deployment of IoT technology in pressure relief systems could enhance monitoring and maintenance, addressing issues of reliability and operational performance. Additionally, manufacturers are increasingly exploring advanced materials and coatings that can withstand harsher environments, which is critical in sectors prone to corrosive conditions. As organizations prioritize sustainability, the shift towards eco-friendly materials and energy-efficient production techniques will also play a significant role in shaping the industry. Embracing these trends can help manufacturers not only to comply with regulatory standards but also to stay competitive in a market that demands high efficiency and safety standards.