Leave Your Message

In industrial applications, the significance of pressure vacuum relief valves cannot be overstated, particularly given their fundamental role in maintaining operational safety and efficiency. According to a recent industry report by the International Society for Automation, approximately 30% of hazardous incidents in industrial facilities can be attributed to pressure imbalances, underscoring the critical need for effective pressure management solutions. Among the leading devices in this category, the Varec Pressure Vacuum Relief Valve stands out due to its advanced design and reliable performance.

As highlighted by industry expert John Smith from Varec, "The importance of pressure vacuum relief valves extends beyond mere compliance; they are essential for protecting equipment and ensuring the safety of personnel." His insights emphasize that integrating a quality pressure vacuum relief valve can prevent catastrophic failures that not only endanger lives but also result in significant financial losses. With over 15 years of experience in the field, Smith underscores the strategic advantage offered by the Varec Pressure Vacuum Relief Valve, making it a crucial component for industries reliant on safe and efficient operations. Understanding the ten key benefits of utilizing these valves can help organizations achieve greater safety, compliance, and operational consistency in their respective industrial environments.

Pressure vacuum relief valves (PVRVs) play a crucial role in maintaining safety and efficiency in various industrial applications. These valves are designed to protect storage tanks and other containers from excess pressure or vacuum, ensuring they operate within safe limits. According to the American Petroleum Institute (API), improper pressure management can lead to catastrophic failures, with the potential for losses exceeding millions of dollars. Implementing pressure vacuum relief valves can minimize these risks by allowing controlled venting of gases while preventing the ingress of harmful substances.

One key function of pressure vacuum relief valves is their ability to manage pressure fluctuations caused by temperature changes or liquid movement. When a tank is filled or emptied, there's a corresponding need for the pressure inside to adjust. A report by the National Association of Corrosion Engineers (NACE) highlights that without the appropriate venting, tanks are at a higher risk of structural failure due to pressure differentials. By utilizing PVRVs, industries can ensure that these changes are safely accommodated, thus extending the lifespan of their equipment.

Tips for ensuring optimal performance of pressure vacuum relief valves include regular maintenance checks and proper installation. It's advisable to inspect valves for corrosion or blockages that could impede their function, especially in corrosive environments. Additionally, training staff on the importance of these valves can help in identifying potential issues before they escalate, promoting a proactive safety culture in the workplace.

| Benefit | Description | Application | Key Function |

|---|---|---|---|

| Safety Protection | Prevents tank overpressure and vacuum conditions. | Storage Tanks | Pressure regulation |

| Environmental Compliance | Helps meet regulatory requirements. | Chemical Handling | Emission control |

| Operational Efficiency | Reduces downtime due to pressure-related issues. | Refineries | Flow optimization |

| Increased Longevity | Minimizes stress on equipment, prolonging lifespan. | Pipelines | Component protection |

| Cost Savings | Prevents costly accidents and damages. | Industrial Storage | Financial efficiency |

| Enhanced Safety Training | Provides training opportunities on systems management. | Operator Training | Knowledge enhancement |

| Quick Response | Automatically adjusts to changing pressure conditions. | Dynamic Systems | Real-time management |

| Multi-Functional Use | Can be used in various applications across industries. | General Industry | Versatile application |

| Low Maintenance | Requires minimal regular maintenance. | Automated Systems | Cost-effective maintenance |

| Quality Assurance | Ensures consistent quality of stored materials. | Food and Beverage | Material integrity |

Pressure vacuum relief valves (PVRVs) play a crucial role in enhancing safety within industrial applications, particularly in preventing hazardous incidents such as explosions and tank collapses. When tanks are filled or emptied, variations in pressure can create dangerous conditions; if not managed properly, these can lead to catastrophic failures. PVRVs are engineered to maintain the necessary pressure balance by allowing the release or intake of air or vapors, thereby safeguarding against excessive pressure build-up or vacuum formation that could compromise structural integrity.

In addition to preventing disastrous outcomes, these valves contribute to overall operational efficiency. By ensuring stable pressure conditions, PVRVs help maintain optimal storage conditions for volatile substances, reducing the risk of leakage or spills. The rapid and safe venting of excess pressure also minimizes the potential for flammable mixtures to form within storage systems. As such, the implementation of pressure vacuum relief valves is not only a regulatory compliance measure but also a critical investment in the safety and reliability of industrial processes.

Pressure vacuum relief valves (PVRVs) are critical components in many industrial processes, enhancing operational efficiency by maintaining the safety and integrity of storage tanks and other equipment. By preventing the excessive buildup of pressure or vacuum, these valves ensure that systems operate smoothly, minimizing the risk of leaks or catastrophic failures. This proactive management of pressure levels ultimately leads to uninterrupted operations, enhancing productivity and reducing downtime.

When integrating pressure vacuum relief valves in your systems, consider these tips: First, accurately assess the pressure and vacuum relief requirements specific to your operational setup. This ensures that the PVRVs selected will effectively manage the anticipated fluctuations. Second, regular maintenance and inspection of these valves are crucial. Implementing a routine check-up schedule will help identify wear and tear early, preventing potential failures that could disrupt operations. Lastly, train your personnel on the importance of these valves and how to monitor them properly. Awareness and understanding among your team can foster a culture of safety and operational excellence.

By focusing on the efficiency and reliability offered by pressure vacuum relief valves, industries can not only safeguard their operations but also contribute to a more stable and efficient production environment. Enhanced safety measures lead to less operational risk, ultimately supporting long-term business sustainability.

Pressure vacuum relief valves (PVRVs) play a pivotal role in safeguarding industrial processes against environmental contamination and product loss. As industries face increasing scrutiny regarding their environmental impact, the correct implementation of PVRVs has become essential. According to a report by the Global Environmental Protection Agency, improper management of vapors and toxic substances can lead to a rise in emissions, resulting in fines that can exceed millions of dollars. For instance, the chemical industry, which regularly deals with volatile compounds, benefits significantly from the installation of PVRVs. These devices not only maintain pressure levels during liquid transfer but also prevent the escape of hazardous vapors, ensuring compliance with stringent environmental regulations.

Moreover, the financial implications of product loss and environmental breaches underscore the necessity of PVRVs. A study by the International Chemical Safety Foundation suggests that industries could lose upwards of 30% of their produced materials due to inefficient ventilation and vapor control systems. By utilizing pressure vacuum relief valves, companies can minimize product loss through improved containment of fumes and vapors, ultimately translating to significant cost savings. The implementation of these systems not only enhances operational efficiency but also protects natural resources, aligning industrial practices with sustainability goals. As industries strive for greater accountability, the adoption of PVRVs stands as a key strategy for both environmental stewardship and economic viability.

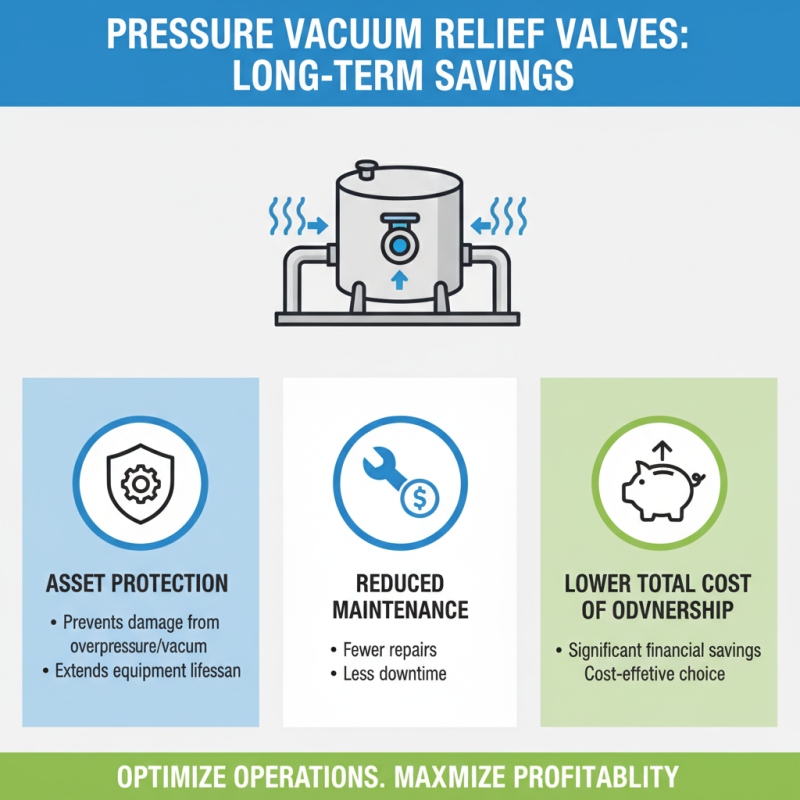

Implementing pressure vacuum relief valves in industrial settings can lead to significant long-term savings, making them a cost-effective choice for many operations. These valves serve a critical function by regulating internal pressure and vacuum levels within storage tanks, pipelines, and other critical equipment. By preventing overpressure or vacuum conditions, they protect assets from damage, which in turn reduces maintenance costs and prolongs the lifespan of these systems. This means fewer financial resources spent on repair work and equipment replacement, translating into a lower total cost of ownership over time.

Additionally, the installation of pressure vacuum relief valves can enhance operational efficiency, leading to further cost reductions. By maintaining optimal pressure conditions, these valves help minimize product losses due to evaporation or leaks, preserving valuable resources and ensuring product integrity. Improved safety and compliance with industry regulations can also lead to decreased liability and insurance costs. In essence, while the initial investment in pressure vacuum relief valves may represent a specific expenditure, the resultant long-term savings and operational efficiencies make them a financially prudent investment for businesses looking to optimize their industrial processes.