Leave Your Message

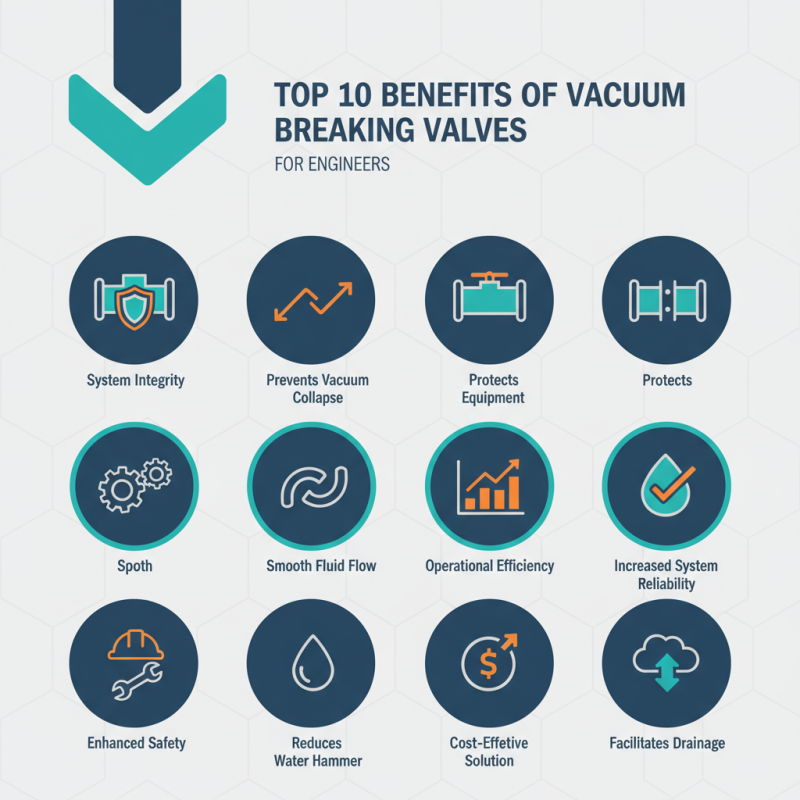

In the realm of fluid management and pressure control, vacuum breaking valves play a pivotal role in ensuring system integrity and operational efficiency. According to Dr. Emily Carter, a renowned expert in fluid dynamics, "The effectiveness of a vacuum breaking valve can significantly reduce the risk of vacuum collapse in pipelines, which is crucial for maintaining system reliability." This underscores the vital importance of understanding the multifaceted benefits that these valves bring to engineering applications.

Engineers and designers must recognize that vacuum breaking valves are not merely ancillary components but are essential elements that enhance the operational safety and performance of various systems. From preventing structural damage due to vacuum conditions to facilitating smooth fluid flow, the advantages of incorporating vacuum breaking valves are manifold. This article delves into the top ten benefits, offering essential insights that can help engineers make informed decisions in their projects, ensuring both efficiency and safety in fluid transport systems.

Vacuum breaking valves are critical components in various engineering applications, particularly in water and sewage systems. Their primary function is to protect piping systems from vacuum conditions that can lead to collapse or damage. According to a report by the American Society of Civil Engineers, approximately 30% of pipeline failures can be attributed to vacuum-related issues, emphasizing the need for effective vacuum prevention strategies. Understanding how vacuum breaking valves work is essential for engineers aiming to enhance system reliability and extend the lifespan of infrastructure.

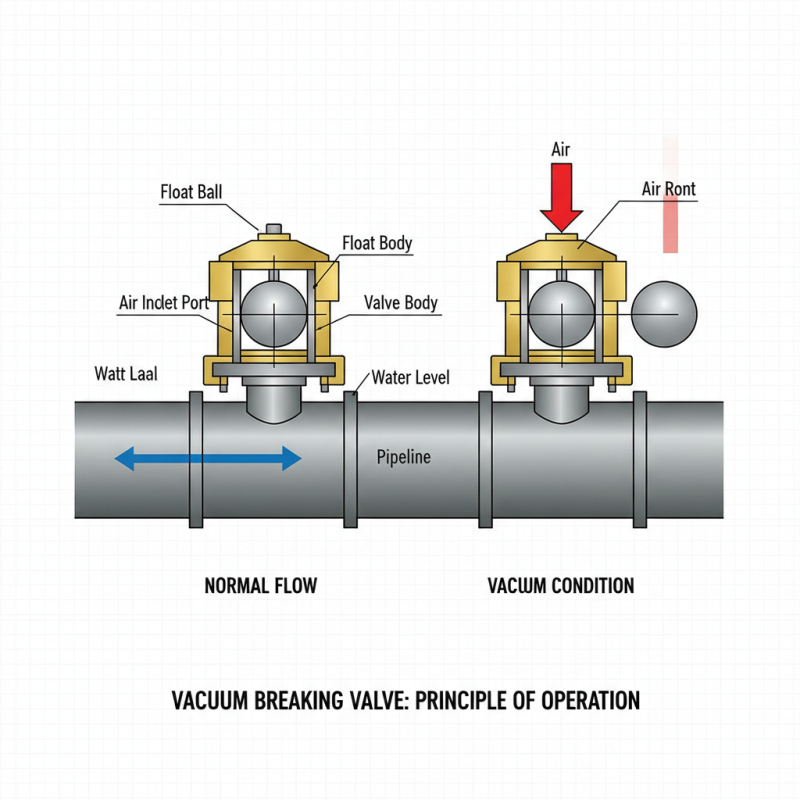

These valves operate by allowing air to enter a pipeline when the internal pressure drops below atmospheric pressure, preventing a vacuum from forming. In a 2021 study published in the Journal of Hydraulics, it was reported that the installation of vacuum breaking valves could reduce the risk of pipeline collapse by over 50%. This data highlights the importance of incorporating these valves into system designs, particularly in areas susceptible to sudden pressure changes, such as during heavy rainfall or rapid fluid withdrawal. Additionally, the integration of vacuum breaking valves not only improves system safety but also optimizes the operational efficiency of fluid transportation networks.

Vacuum breaking valves play a crucial role in various engineering applications, particularly in preventing the formation of vacuum conditions that can lead to system failures. These valves are designed to automatically allow air into the system when a vacuum forms, thereby equalizing pressure and mitigating risks associated with collapsing pipes or destructive operational conditions. Understanding their key functions and mechanisms is essential for engineers involved in fluid control systems.

One of the primary mechanisms of vacuum breaking valves is their spring-loaded design, which ensures quick responsiveness to changes in pressure. When a negative pressure is detected, the valve opens, permitting air to flow into the system. This process not only protects the integrity of the piping infrastructure but also enhances operational efficiency by preventing disruptions in flow. Additionally, some valves feature integrated sensors that provide real-time monitoring, further improving safety and reliability.

Tips: When selecting vacuum breaking valves for your systems, always consider compatibility with the fluids being handled and the specific environmental conditions. Regular maintenance checks are recommended to ensure the valves function correctly over time, as wear can affect performance. Lastly, consider implementing redundant systems for critical applications, ensuring that even in a failure scenario, the risk of vacuum-related incidents is minimized.

Vacuum breaking valves play a crucial role in various engineering applications, offering a range of advantages that enhance system efficiency and safety. One of their main benefits is the prevention of vacuum conditions within pipelines, which can lead to collapse and significant structural damage. By maintaining atmospheric pressure, these valves ensure that fluid flow remains uninterrupted and systems operate smoothly, reducing downtime and maintenance costs.

Tips for implementation: When installing vacuum breaking valves, it's essential to ensure they are strategically placed at points where a vacuum is likely to occur. This proactive approach can significantly mitigate risks associated with pressure fluctuations and protect the integrity of your systems. Regular inspection and maintenance are also critical to ensure that the valves function correctly, guaranteeing consistent performance.

Another noteworthy advantage is the conservation of water resources. Vacuum breaking valves can help optimize water usage in irrigation systems by maintaining required pressure levels, promoting efficient flow, and reducing wastage. This not only supports environmental sustainability but also enhances the overall effectiveness of resource management in engineering projects. Implementing these valves can lead to improved system resilience and cost savings over time.

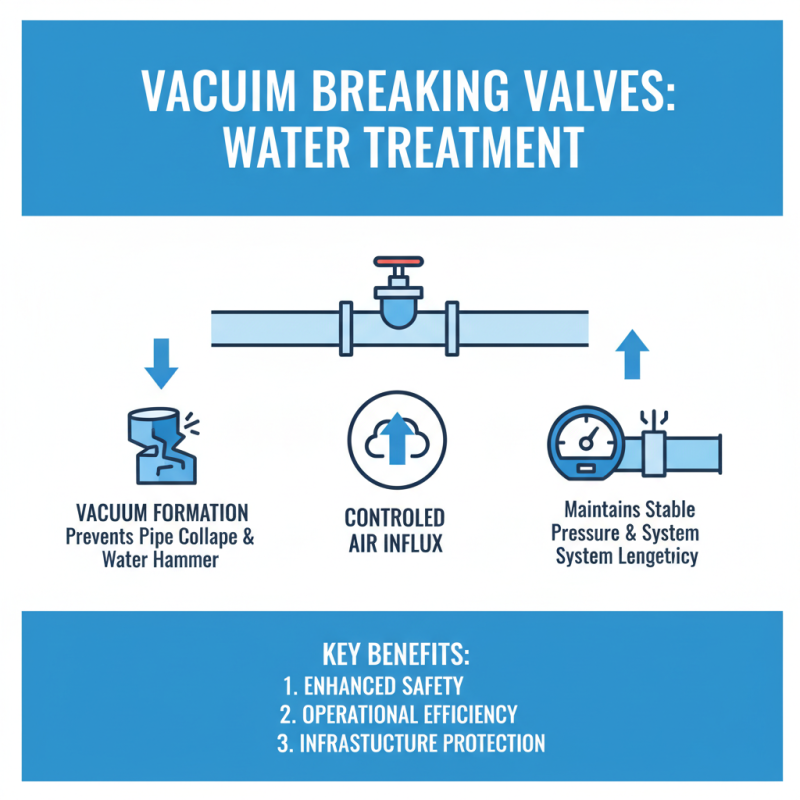

Vacuum breaking valves are crucial components across various industries, facilitating safety and efficiency in fluid management systems. In the water treatment sector, these valves prevent the formation of vacuum conditions that can lead to pipe collapses or water hammering. By ensuring that there is a controlled influx of air into the system, vacuum breaking valves help maintain stable pressure levels, which is essential for the longevity of pipelines and associated infrastructure.

In the food and beverage industry, vacuum breaking valves play a significant role in the processing and transportation of liquids. They help maintain product integrity by preventing contamination and ensuring that vacuum conditions do not affect the flow of sensitive materials. Additionally, in the chemical manufacturing sector, these valves protect equipment by minimizing the risks associated with sudden pressure changes, thereby contributing to safer operational environments. Their versatility and essential function make vacuum breaking valves integral to diverse industrial applications.

Maintenance of vacuum breaking valves is critical to ensure their optimal performance and longevity. Regular inspections should be conducted to check for signs of wear, corrosion, or debris buildup, which can impair the valve’s functionality. Engineers should develop a routine maintenance schedule that includes cleaning the valve components, verifying the seal integrity, and testing the valve’s operational response under various conditions. Ensuring that all connections are tight and leak-free plays a vital role in maintaining system reliability and preventing potential failures.

Best practices for vacuum breaking valves also encompass proper installation techniques and system design considerations. Engineers should always refer to guidelines for the correct placement of valves to maintain the intended vacuum pressure levels. Additionally, incorporating pressure relief mechanisms can provide an extra layer of protection against overpressure scenarios. Training personnel in the correct operating procedures and the importance of regular maintenance can further enhance the efficacy of vacuum breaking valves, ultimately leading to improved system performance and reduced downtime.