Leave Your Message

In the realm of industrial safety, the significance of an Inline Flame Arrestor cannot be understated. These devices play a crucial role in preventing the propagation of flames within gas and vapor systems, ensuring that operations remain safe and efficient. As Dan Thompson, a leading expert in industrial safety solutions, aptly stated, "Investing in high-quality Inline Flame Arrestors is not just a regulatory measure; it's a commitment to protecting your workforce and your assets."

This sentiment resonates deeply within industries that handle flammable materials, where the risks of fire and explosion are ever-present. The right Inline Flame Arrestor can drastically reduce these risks while maintaining optimal performance in various applications. With countless options available on the market, selecting the best flame arrestor can be daunting. In this article, we will explore the ten best Inline Flame Arrestors, highlighting their features, benefits, and what makes them exemplary choices for enhancing safety and performance in industrial settings.

Understanding the nuances of these devices is essential for operators and safety managers looking to fortify their systems against potential hazards. By examining the top performers in the industry, we aim to equip professionals with the knowledge to make informed decisions tailored to their specific operational needs.

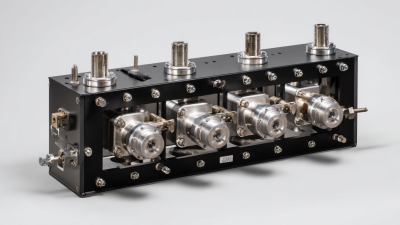

Inline flame arrestors are crucial components in industrial applications, designed to enhance safety by preventing the spread of flames through conduits. One key feature of these devices is their ability to withstand high temperatures and pressures, ensuring that they can operate safely in hazardous environments. Made from durable materials, such as stainless steel and other heat-resistant alloys, these arrestors provide robust protection against potential ignition sources while allowing for efficient gas or fluid flow.

Another essential characteristic is the design of the flame arrestor mechanism itself. Many inline flame arrestors utilize a series of intricate baffles or mesh screens that cool and extinguish flames before they can propagate. This design not only meets stringent industrial safety standards but also minimizes pressure drops that could hinder system performance. Furthermore, reliable manufacturers often offer models equipped with features like easy maintenance access and pressure monitoring, which contribute to improved operational efficiency and long-term reliability in industrial settings.

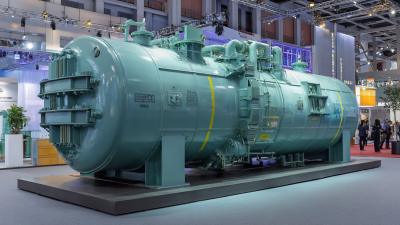

The application of inline flame arrestors in combustible gas management is critical for enhancing safety in various industrial settings. These devices play a pivotal role in preventing the propagation of flame through gas pipelines, thereby protecting infrastructure and personnel from potential hazards associated with explosive gases. Their use is particularly vital in industries such as oil and gas, chemical manufacturing, and wastewater treatment, where flammable gases are frequently present. Effective management of these gases not only minimizes the risk of fire incidents but also ensures compliance with safety regulations.

Recent discussions surrounding fire safety have brought attention to the importance of stringent control measures in construction and industrial environments. The scrutiny of building materials and inspection practices, as highlighted by recent news reports, underscores the necessity of employing comprehensive safety devices like inline flame arrestors to mitigate risks. By integrating these technologies into gas management systems, industries can foster a safer work environment and enhance overall operational efficiency. Such measures are essential for preventing disasters that have historically occurred due to inadequate safety practices.

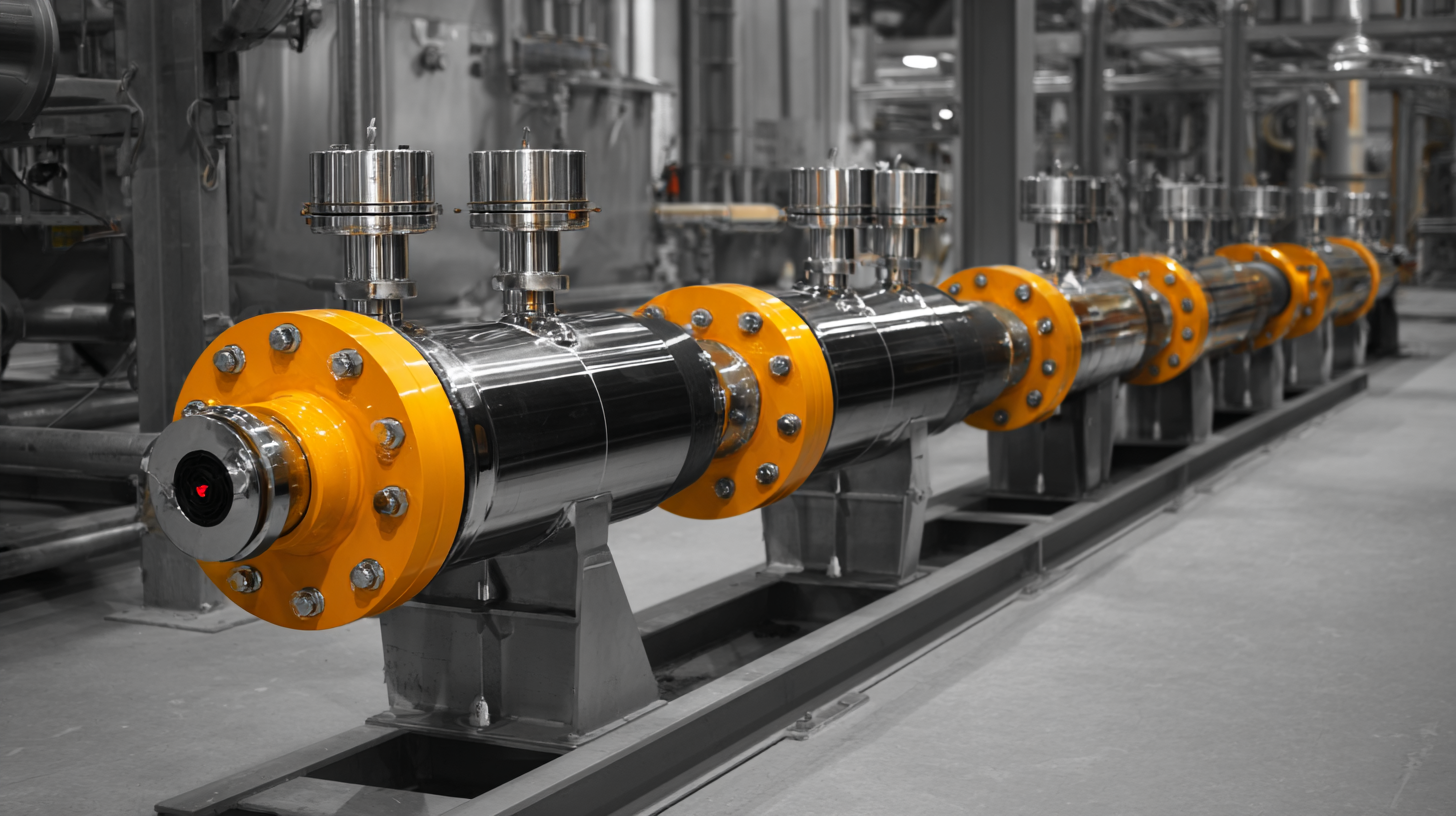

When selecting inline flame arrestors for industrial applications, performance metrics play a crucial role in ensuring both safety and efficiency. Key parameters include the arrestor's pressure drop, maximum operating temperature, and material compatibility. According to the Industrial Safety Standards Report 2022, a pressure drop of less than 5 psi is ideal, as this minimizes energy loss while maintaining desired flow rates. The report states that systems featuring arrestors with optimal pressure characteristics can improve overall system efficiency by up to 15%.

Another significant metric is the arrestor's thermal endurance, typically indicated by its maximum operating temperature. Studies show that flame arrestors designed to withstand temperatures exceeding 950°F exhibit a lower failure rate, thus enhancing safety in high-risk environments. Additionally, materials such as stainless steel or carbon steel with proper coatings have been shown to improve durability and resistance against corrosive substances, as detailed in the Advanced Materials for Industrial Applications report. This robustness is essential, given that failure to maintain integrity can lead to catastrophic incidents and substantial financial losses, potentially upwards of $1 million, as highlighted by the Loss Prevention Association.

Ultimately, thorough evaluation of these performance metrics can lead to more informed decisions, resulting in greater safety and reliability in industrial operations.

| Model | Material | Diameter (inches) | Pressure Rating (psi) | Temperature Rating (°F) | Efficiency (%) | Applications |

|---|---|---|---|---|---|---|

| Model A | Stainless Steel | 2 | 150 | 500 | 98 | Natural Gas |

| Model B | Carbon Steel | 3 | 200 | 450 | 95 | Diesel Fuel |

| Model C | Aluminum | 4 | 250 | 600 | 99 | Propane |

| Model D | Brass | 1.5 | 100 | 300 | 92 | Biodiesel |

| Model E | Composite | 2.5 | 150 | 550 | 97 | Chemical Processing |

When choosing inline flame arrestors for industrial applications, understanding regulatory compliance and certification standards is crucial.

Flame arrestors must meet specific guidelines to operate safely and effectively, mitigating risks in environments where flammable vapors or gases are present.

Common standards include those set by organizations like the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL).

It's essential to verify that the flame arrestors you select are tested and certified according to these guidelines to ensure they provide the necessary protection.

Tips for ensuring compliance include regularly reviewing updates to safety standards and conducting thorough assessments of your equipment supplier's certifications.

Proper installation is equally important, as it can significantly affect the performance of the flame arrestor.

Always follow the manufacturer’s installation recommendations and consider professional assistance if needed.

Additionally, periodic maintenance checks are vital to keep flame arrestors functioning optimally.

Inspecting for signs of wear and ensuring that they remain free from obstructions can enhance their performance and longevity.

Keeping records of inspections and maintenance can also help demonstrate compliance during audits or inspections, ultimately contributing to a safer working environment.

When selecting inline flame arrestors for industrial applications, efficiency is paramount. A comparative analysis of top brands reveals variations in design, material, and performance features that significantly impact safety. High-quality flame arrestors employ advanced materials that enhance their thermal stability and resistance to corrosive environments. This results in improved durability and longer service life, which are crucial for industries operating in high-risk scenarios. Brands with robust engineering processes often offer products that demonstrate superior flame quenching capabilities, effectively preventing the propagation of flames through vent systems.

Moreover, the efficiency of inline flame arrestors can be measured not only by their ability to extinguish flames but also by their pressure drop characteristics. Brands that optimize their designs to minimize pressure loss ensure that industrial systems maintain operational efficiency without compromising safety. A thorough examination of these elements across various models leads to informed choices that enhance both safety and performance in critical industrial settings. As industries continue to evolve, the demand for reliable and efficient flame arrestors will likely grow, necessitating constant innovation and adaptation from leading manufacturers.