Leave Your Message

In the world of fluid and gas management, the importance of a properly functioning Vacuum Relief Valve (VRV) cannot be overstated. According to a recent industry report by Grand View Research, the global market for vacuum relief valves is anticipated to reach $1.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.5%. This growth is driven by the increasing demand for effective pressure management systems across various sectors such as oil and gas, pharmaceuticals, and food processing. As industries seek to optimize their operations, understanding the real-world applications of VRVs becomes crucial. This blog will explore top strategies to enhance the performance of vacuum relief valves, ensuring not just compliance with safety standards but also improved operational efficiency and cost savings.

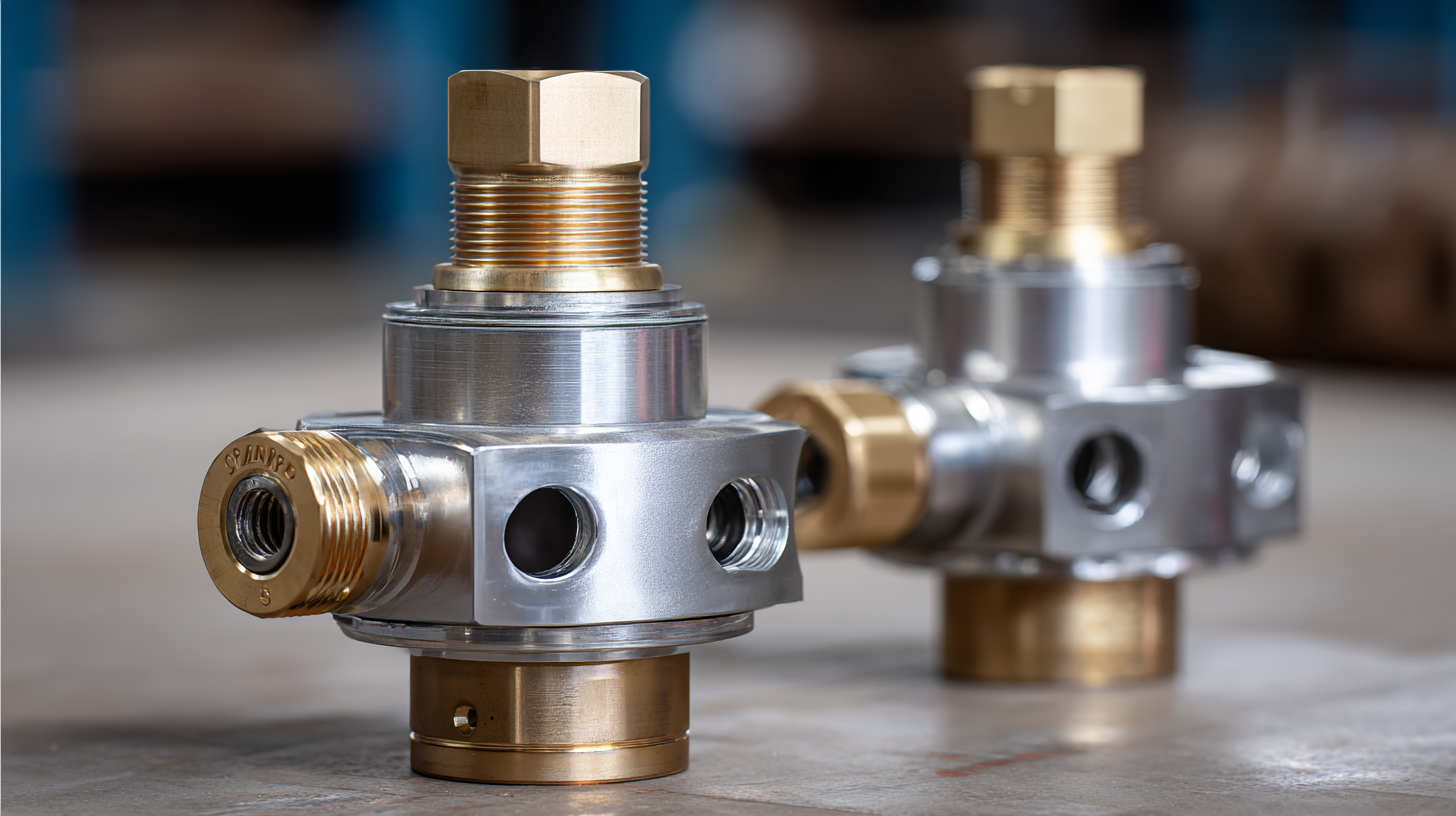

Understanding Vacuum Relief Valves: Function and Importance in Industrial Applications

Vacuum relief valves (VRVs) play a crucial role in maintaining the integrity of industrial systems by preventing vacuum conditions that could lead to equipment failure. These devices are designed to automatically open and admit air into a system when a certain negative pressure threshold is reached, thus preventing structural collapse or damage to vessels and piping. According to a report by the American Society of Mechanical Engineers (ASME), improper vacuum management can lead to equipment failure, resulting in downtime and maintenance costs that can exceed 20% of the total operational budget in industrial settings.

In applications such as chemical processing and oil refining, maintaining optimal pressure levels is vital for safety and efficiency. A study conducted by the Chemical Engineering Magazine highlighted that systems equipped with properly functioning vacuum relief valves demonstrated a 30% reduction in product loss due to leaks and ruptures compared to those without. Furthermore, effective VRVs can enhance energy efficiency by preventing excessive energy consumption associated with compensating for pressure loss. With these statistics in mind, it is evident that investing in high-quality vacuum relief valves and optimizing their performance can significantly improve operational reliability and reduce overall costs in various industrial applications.

In the rapidly evolving landscape of industrial applications, vacuum relief valves play a critical role in ensuring operational safety and efficiency. Key features of high-performance vacuum relief valves include their ability to maintain optimal pressure levels, prevent vacuum formation that could lead to system failures, and facilitate the efficient transfer of materials. The global industrial vacuum valves market is projected to surpass USD 1.6 billion, reflecting a robust demand driven by advancements in manufacturing processes and the need for reliable systems in diverse applications.

Advanced designs of vacuum relief valves incorporate innovative materials and technologies that enhance performance under extreme conditions. For instance, optimizing these valves can involve the integration of smart sensors that monitor system performance in real-time, addressing challenges in hydraulic fluid power systems used in various engineering sectors. As industries continue to embrace automation and efficiency, the importance of high-performance vacuum relief valves will only grow, supporting cleaner production methods and sustainability efforts across the board.

In the manufacturing sector, the implementation of vacuum relief valves has led to remarkable enhancements in operational efficiency and safety. Case studies from various companies reveal how these valves have been pivotal in optimizing production processes. For instance, companies in Batu Kawan Industrial Park have shared success stories about how vacuum relief valves have mitigated the risks associated with system overpressurization, thereby improving the consistency of their manufacturing practices. By effectively managing vacuum conditions, these valves ensure that production can proceed without interruptions, leading to increased output and reduced downtime.

Another compelling example is from the recent research on 3/16” tubing, which highlighted its effectiveness in maintaining vacuum performance without significant elevation drop. This advancement has helped manufacturers to enhance their systems, ensuring that vacuum relief valves operate at peak performance. The ability to properly optimize valve functionality not only prevents equipment damage but also contributes to overall process reliability. Such real-world applications exemplify the crucial role vacuum relief valves play in modern manufacturing, showcasing how strategic investments in equipment can yield significant long-term benefits.

| Case Study | Industry | Problem | Solution Implemented | Results |

|---|---|---|---|---|

| Case Study 1 | Food Manufacturing | Frequent system failures due to vacuum loss | Implemented high-performance vacuum relief valves | Reduced downtime by 30% and improved production efficiency |

| Case Study 2 | Pharmaceuticals | Contamination risk from vacuum fluctuations | Installed advanced sensors and vacuum relief systems | Eliminated contamination incidents and ensured product safety |

| Case Study 3 | Chemical Processing | Inefficient vacuum recovery leading to losses | Optimized vacuum relief valve settings and sizes | Increased efficiency by 25% and reduced operational costs |

| Case Study 4 | Oil and Gas | Inconsistent vacuum levels affecting extraction | Upgraded to automated vacuum relief valves | Enhanced extraction rates by 15% and improved safety |

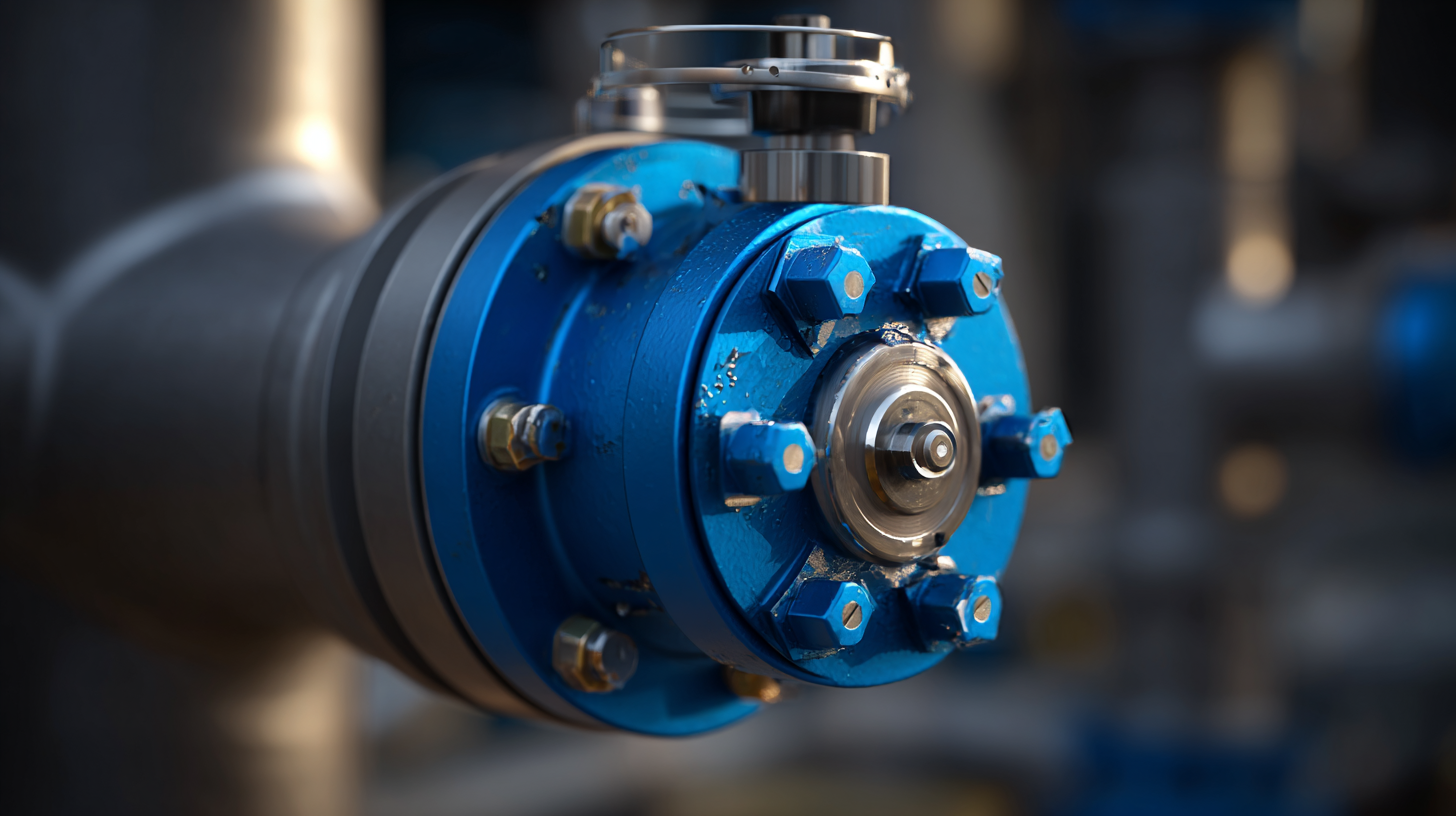

Installing and maintaining vacuum relief valves is crucial for ensuring system efficiency and safety in various industrial applications. One key best practice during installation is to select the right valve size and type that suits the specific requirements of your system. This involves calculating the maximum and minimum pressure conditions, as well as considering the flow characteristics of the materials being handled. Proper positioning of the valve is also essential; it should be installed in a location where it can effectively relieve excessive vacuum conditions without obstruction or turbulence that could compromise its functionality.

Regular maintenance is equally important to optimize the performance of vacuum relief valves. Schedule routine inspections to check for signs of wear, corrosion, or blockages that may hinder valve operation. Cleaning the valve and its surroundings can prevent buildup that could lead to malfunction. Additionally, testing the valve periodically ensures that it opens and closes properly under varying pressure conditions. Documenting maintenance activities and any changes made to the system helps track performance over time, allowing for timely adjustments or replacements when needed. By adhering to these best practices, you can ensure your vacuum relief valves operate efficiently and reliably, safeguarding your industrial processes.

The future of vacuum relief valve technology is increasingly leaning towards automation and enhanced efficiency. As industries strive for greater precision and reliability, the integration of smart sensors and IoT connectivity into vacuum relief valves is paving the way for real-time monitoring and data analysis. These advancements not only optimize performance by ensuring the valves open and close at the right moments, but they also minimize waste and reduce the risk of system failures. Industries are now able to maintain optimal pressure levels more effectively, thus prolonging the lifespan of equipment and ensuring safety standards are met.

Global manufacturing insights reveal a shift towards sustainable practices and materials in the production of vacuum relief valves. Manufacturers are focusing on eco-friendly alternatives, such as recyclable materials and energy-efficient production techniques. This not only addresses the growing demand for sustainable solutions but also aligns with regulatory pressures for reducing carbon footprints. Additionally, as international supply chains evolve, manufacturers are investing in localized production to enhance resilience and reduce lead times, allowing for a more responsive approach to market demands and technological advancements in vacuum relief systems.