Leave Your Message

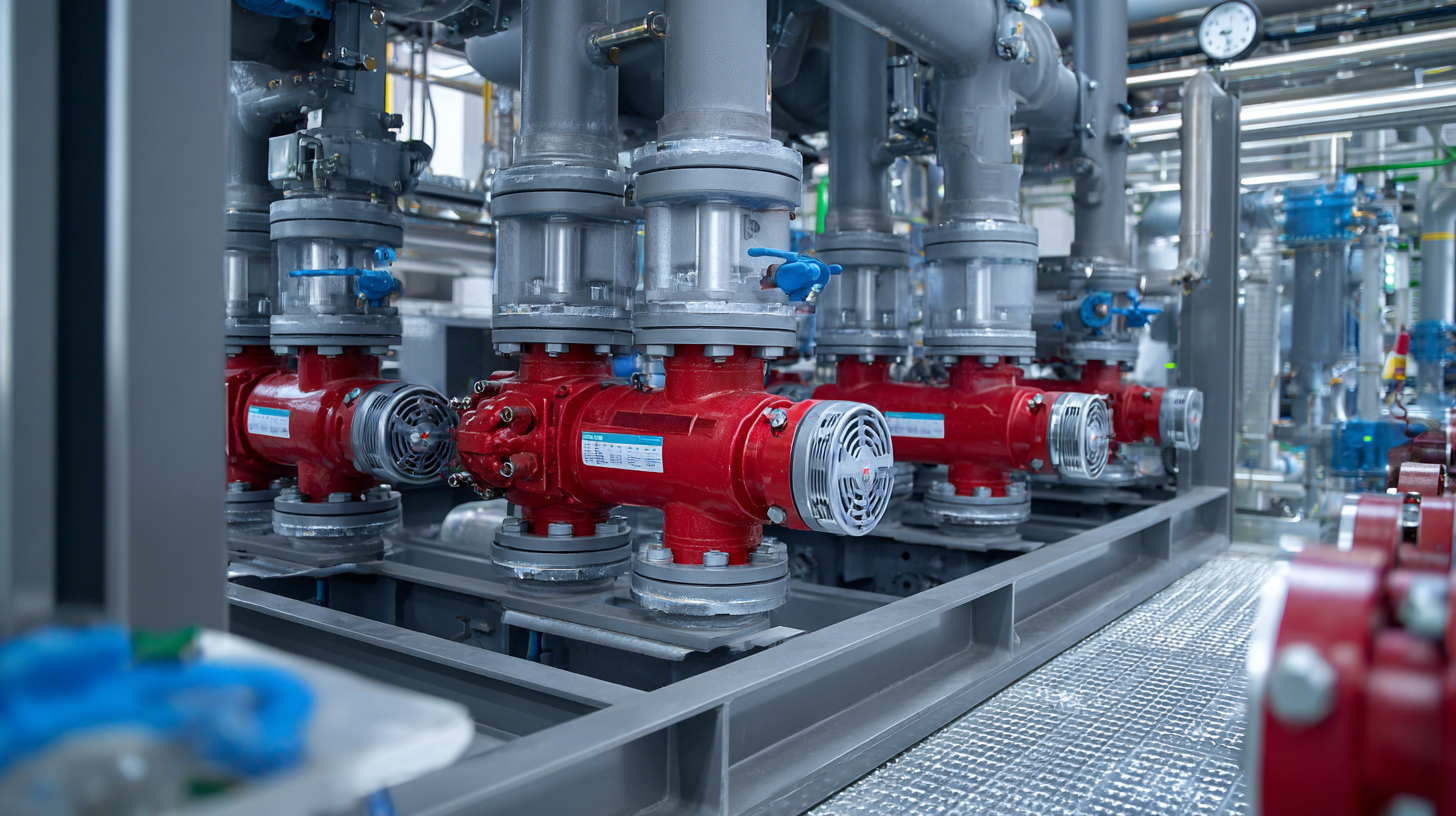

In the industrial landscape, the importance of a Vacuum Breaking Valve cannot be overstated, as these valves play a critical role in maintaining system integrity and safety. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $88.3 billion by 2025, highlighting the increasing need for specialized valve solutions, including vacuum breaking valves, across various sectors such as oil and gas, water management, and chemical processing. As industries strive for greater efficiency and safety, choosing the right vacuum breaking valve can significantly enhance operational performance and prevent potential environmental hazards. This ultimate checklist will guide you through the essential considerations and alternatives available, ensuring you make an informed decision tailored to your specific needs.

Vacuum breaking valves play a crucial role in various industrial applications, especially in preventing vacuum formation that can lead to equipment malfunction or damage. Understanding the key features and functions of these valves is essential for selecting the right one for your needs. According to a recent industry report by Grand View Research, the global market for vacuum technology is projected to reach USD 38.95 billion by 2025, highlighting the increasing demand for reliable and efficient vacuum management solutions.

One of the primary functions of vacuum breaking valves is to protect systems from negative pressures. When a fluid is drained from a tank or pipeline, a vacuum can be created, potentially causing collapse or damage. Vacuum breaking valves are designed to allow air to enter the system, equalizing pressure and safeguarding equipment integrity. Key features to consider include materials that resist corrosion and high temperatures, as well as size and flow capacity, which should align with your specific operational requirements. A study from the International Journal of Engineering Research and Technology indicates that the right selection of a vacuum breaking valve can increase overall system efficiency by up to 20%, making informed choices imperative for optimal performance.

This bar chart represents the key features and functions of vacuum breaking valves that are critical for selecting the best option for your needs.

When it comes to choosing the best vacuum breaking valve for your needs, quality standards play a crucial role in ensuring reliability and performance. One important aspect to consider is the country of origin, particularly focusing on products labeled "Made in China." In recent years, China has significantly improved its manufacturing processes and quality control measures, making it possible to find high-quality vacuum valves that meet international standards. Being aware of these enhancements allows buyers to make informed decisions while navigating the complexities of the global market.

"Made in China" no longer carries the stigma it once did. Many Chinese manufacturers have adopted cutting-edge technologies and adhere to stringent quality certifications. This shift not only enhances product durability and efficiency but also offers competitive pricing. When selecting a vacuum breaking valve, it's essential to evaluate the manufacturer's reputation, certifications, and customer feedback. A thorough assessment can reveal whether a product genuinely meets the quality standards you require, ultimately ensuring that your investment results in reliable and efficient performance.

When selecting the best vacuum breaking valve, understanding the performance and reliability of top brands in the market is crucial. According to a recent industry report by Research and Markets, the global vacuum breakers market is projected to grow at a CAGR of 4.5% over the next five years, highlighting the increasing demand for reliable and efficient solutions in various industries. Notably, brands like Anderson and Watson McDaniel stand out for their innovative designs and robust performance records. Anderson, for instance, boasts a 99% reliability rating based on customer feedback and extensive testing, making it a top choice for many applications.

**Tip:** When comparing brands, consider the materials used in valve construction. High-quality materials can significantly impact longevity and effectiveness, particularly in high-pressure environments.

Moreover, performance metrics such as flow capacity and pressure drop should guide your selection process. According to a comparative analysis published by the American Society of Mechanical Engineers (ASME), valves that maintain low pressure drops while offering high flow rates tend to perform better in real-world applications. Brands like Cash Acme are recognized for their exceptional flow rates, setting industry benchmarks.

**Tip:** Always consult performance graphs and charts, which can provide valuable insights into how a valve will operate under various conditions. This data can help ensure that you choose the right valve for your specific requirements.

| Model | Flow Rate (GPM) | Pressure Rating (PSI) | Material | Weight (lbs) | Warranty (Years) | User Rating (1-5) |

|---|---|---|---|---|---|---|

| Model A | 15 | 150 | PVC | 5 | 3 | 4.2 |

| Model B | 20 | 200 | Stainless Steel | 6 | 5 | 4.8 |

| Model C | 10 | 120 | Brass | 4 | 2 | 4.0 |

| Model D | 25 | 250 | Aluminum | 7 | 4 | 4.5 |

| Model E | 18 | 180 | Polypropylene | 5.5 | 3 | 4.1 |

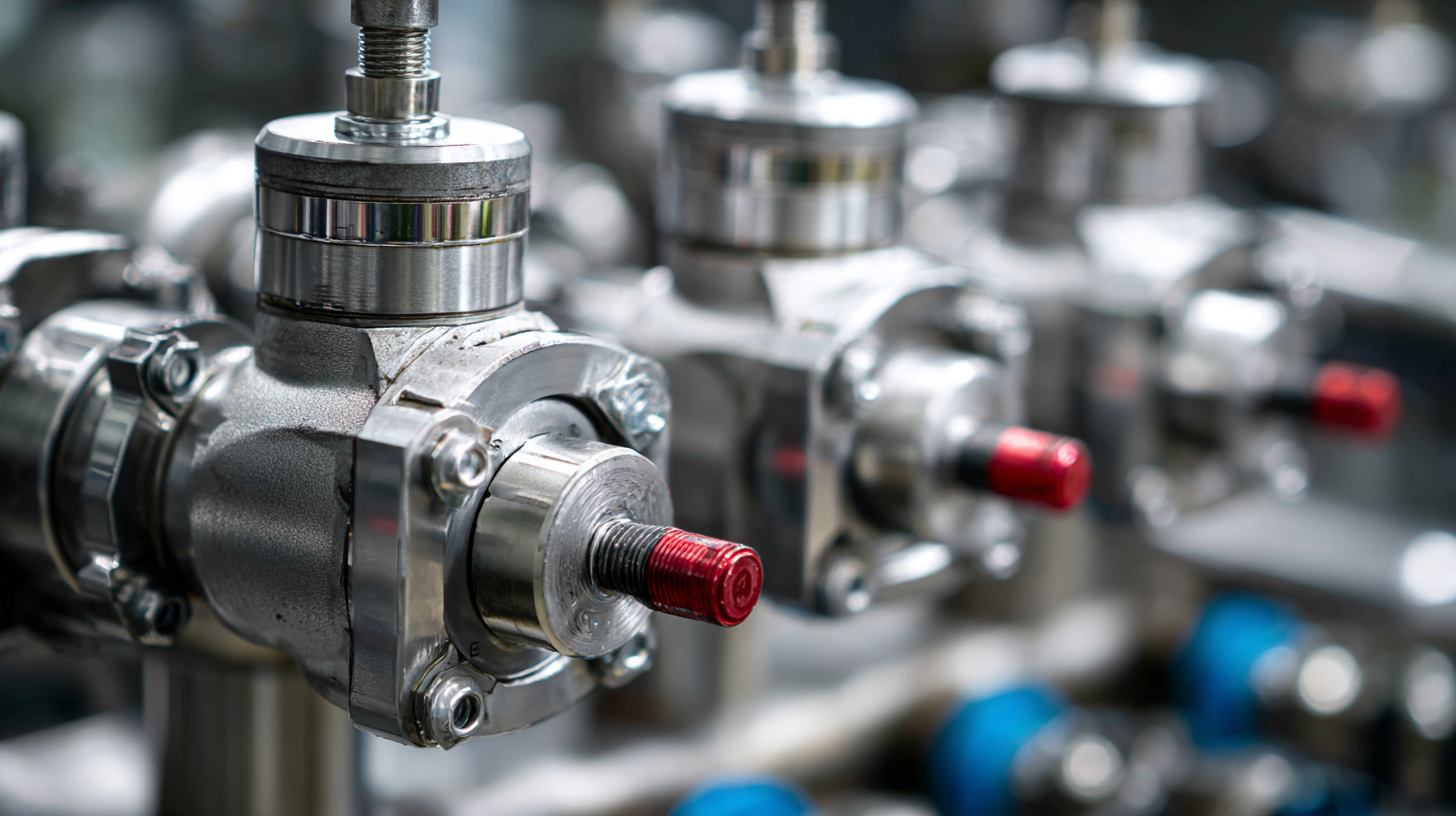

When selecting a vacuum breaking valve, one of the most critical aspects to consider is the size and type that best fits your application. The right size ensures that the valve can effectively manage the pressure fluctuations and vacuum conditions specific to your system. Calculate the flow rate requirements and evaluate the diameter of the pipelines involved. A valve that is too small may restrict flow and create unnecessary stress on the system, while an oversized valve could lead to inadequate control, compromising system efficiency.

Additionally, the type of vacuum breaking valve plays a significant role in its performance. There are various designs, including pilot-operated, direct acting, and vacuum relief valves, each suited for different environments and applications. For instance, pilot-operated valves are ideal for systems requiring precise control, while direct acting valves can handle simpler applications. Understanding the unique demands of your system will help you select a valve that not only fits physically but also performs optimally under your specific conditions. By addressing both size and type, you can ensure a successful operation of your vacuum systems.

When investing in a vacuum breaking valve, understanding the importance of regular maintenance is essential for maximizing its lifespan and ensuring optimal performance. According to industry reports, proper maintenance can extend the life of a vacuum breaking valve by up to 50%. This emphasizes the need for routine checks and timely repairs to avoid costly replacements. Regular tasks such as cleaning, inspection for wear and tear, and ensuring proper sealing can significantly enhance the valve's efficiency and functionality.

Moreover, just as with other home appliances, periodic maintenance practices can prevent major failures that may result in expensive repairs. Industry experts suggest conducting biannual inspections to assess the valve's condition and performance metrics. This includes checking for leaks, assessing operating pressures, and verifying the valve's responsiveness. Additionally, following a strategic maintenance schedule not only prolongs the equipment's life but also optimizes energy efficiency, which can lead to substantial cost savings over time. By investing in these maintenance practices, users can rest assured that their vacuum breaking valves will operate effectively and sustainably for years to come.