Leave Your Message

Selecting the appropriate Blanket Gas Regulator is crucial for maintaining optimal pressure control in various industrial applications. According to the Gas Processors Association (GPA), effective pressure management can lead to significant improvements in operational efficiency and safety, reducing gas loss by as much as 20%. Additionally, the American Petroleum Institute (API) emphasizes that using the correct regulator minimizes the risk of system failures, which can result in costly downtime and safety hazards.

Selecting the appropriate Blanket Gas Regulator is crucial for maintaining optimal pressure control in various industrial applications. According to the Gas Processors Association (GPA), effective pressure management can lead to significant improvements in operational efficiency and safety, reducing gas loss by as much as 20%. Additionally, the American Petroleum Institute (API) emphasizes that using the correct regulator minimizes the risk of system failures, which can result in costly downtime and safety hazards.

With a myriad of options available in the market, understanding the specifications and capabilities of Blanket Gas Regulators becomes essential. Factors such as flow rate, material compatibility, and pressure ranges must be evaluated carefully to ensure reliable performance. This guide aims to provide insights on choosing the right regulator, helping industries enhance their gas handling systems while adhering to best practices in safety and performance.

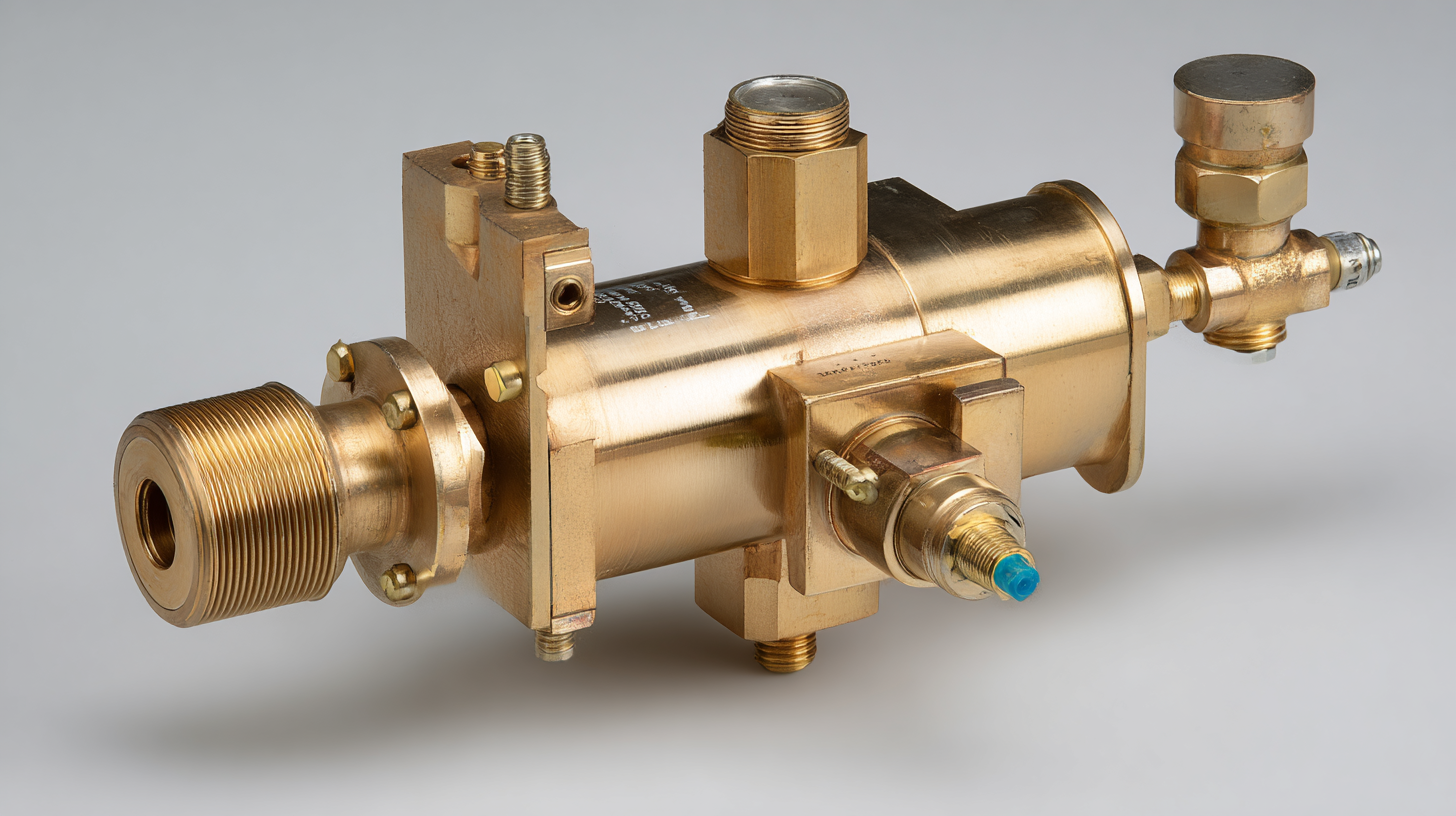

Blanket gas regulators play a crucial role in maintaining optimal pressure control across various industrial applications, particularly in the petrochemical and food processing industries. According to a report by the Gas Processors Association, nearly 40% of equipment failures are linked to improper pressure regulation, underscoring the significance of selecting the right blanket gas regulator. These regulators help maintain a consistent internal pressure within storage tanks or reactors, ensuring that gas is kept at a safe and functional level, thereby minimizing the risk of leaks and explosive atmospheres.

The performance of blanket gas regulators can significantly influence operational efficiency and product quality. A study conducted by the American Society of Mechanical Engineers found that appropriate pressure regulation not only enhances safety but also optimizes the flow rate in gas distribution systems, resulting in a reduction of energy costs by up to 15%. As industries strive for sustainability and cost-effectiveness, understanding the technical specifications, such as flow capacity and pressure range, becomes vital for choosing the right regulator that meets specific operational needs. The implementation of high-quality blanket gas regulators is essential for reliable pressure control and stable production processes.

Choosing the right blanket gas regulator is crucial for maintaining optimal pressure control in various applications, including packaging and fermentation processes. When selecting a blanket gas regulator, there are several key factors that one should consider. Firstly, understanding the pressure requirements of your system is essential. Ensure that the regulator can handle the specific pressure ranges necessary for your operations to avoid disruptions and maintain efficiency.

Another important aspect to consider is the compatibility of the regulator with the gas being used. Different gases have unique properties, and not all regulators are suitable for every type. For example, if you are dealing with corrosive or reactive gases, you must choose a regulator made from materials that can withstand those conditions. This prevents leaks and potential hazards.

Tips: Always check for certifications and standards that the regulator meets to ensure safety and reliability. It's also wise to consult with manufacturers or suppliers to get recommendations based on your specific needs. Additionally, consider the ease of maintenance and availability of replacement parts, as this can save you from downtime in the long run.

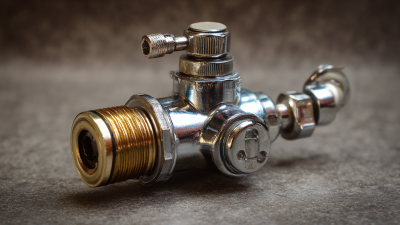

When it comes to selecting the appropriate blanket gas regulator, understanding the various types available is crucial for ensuring optimal pressure control in a range of applications. The most common types include spring-loaded regulators, dome-loaded regulators, and electronic regulators.

Spring-loaded regulators are ideal for low- to medium-pressure applications, providing reliable performance for processes that demand stable pressure but are sensitive to minor fluctuations. They are often used in industries such as food and beverage, where precise control is essential.

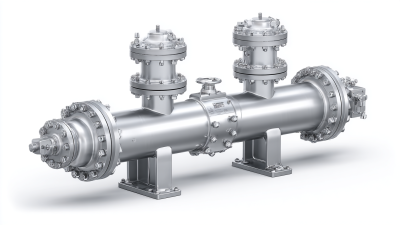

Dome-loaded regulators, on the other hand, are designed for high-pressure situations and are often employed in environments where pressure variations can lead to significant operational issues. These regulators utilize a dome mechanism to maintain consistent outlet pressure despite fluctuations in inlet pressure, making them suitable for applications in chemical processing and pharmaceuticals.

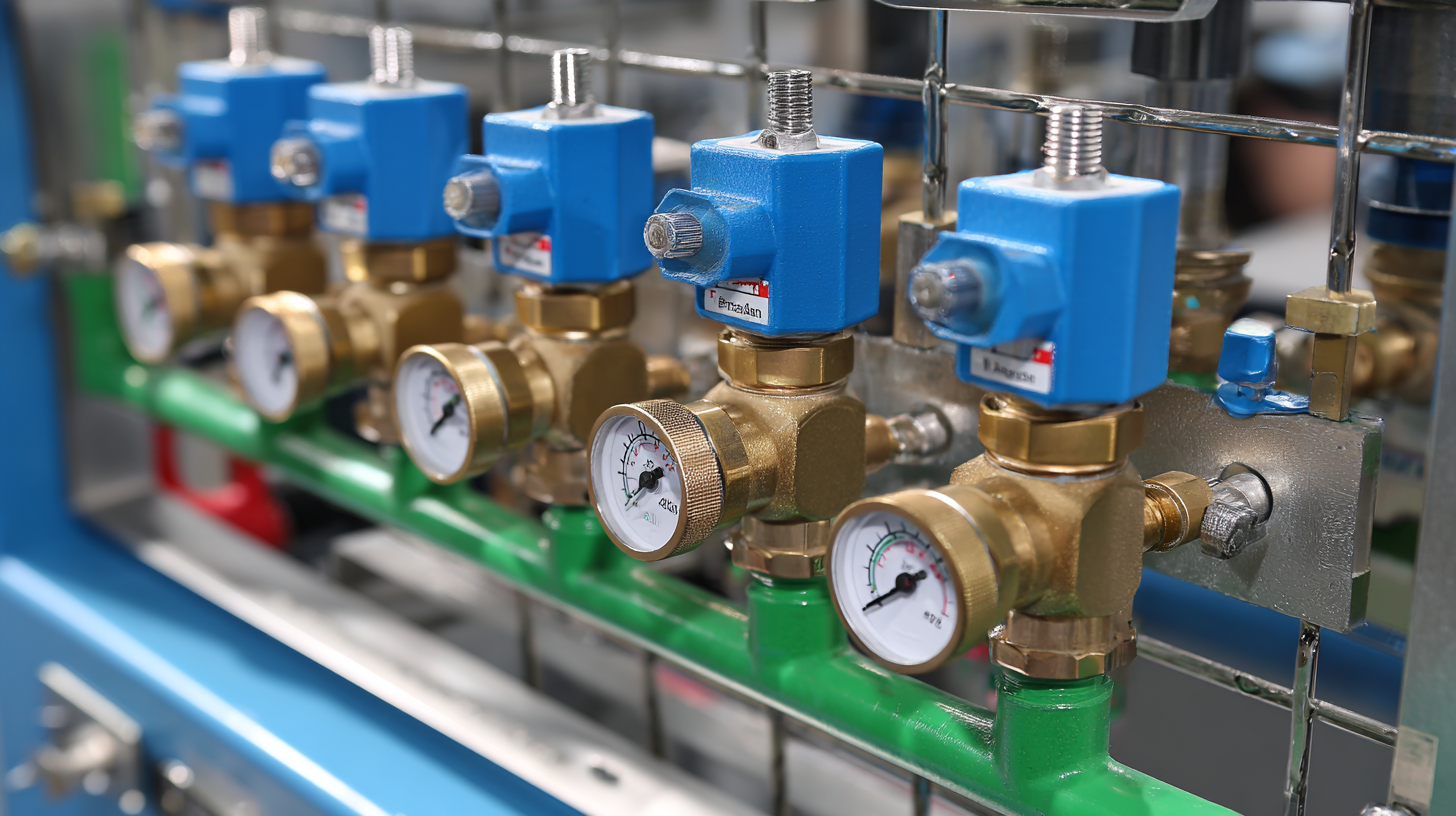

Electronic regulators provide advanced control capabilities, allowing for remote monitoring and adjustments, which is increasingly valuable in automated systems and high-tech manufacturing environments. Each type of regulator has distinct advantages, and the choice ultimately depends on the specific requirements of the application at hand.

When selecting a blanket gas regulator, it is crucial to assess its compatibility with your specific gas system to ensure optimal pressure control and safety. Industry reports indicate that improper regulator selection can lead to pressure fluctuations that may compromise the integrity of the entire system. For example, a study by the Gas Technology Institute revealed that up to 15% of gas supply issues stem from mismatched regulators and systems, which can significantly increase operational costs and downtime.

To evaluate compatibility, consider the gas type, pressure requirements, and the regulator’s specifications. High purity gases, for instance, require regulators with specific materials to prevent contamination. According to a report from the American Society of Mechanical Engineers, using a regulator designed for industrial gas services in a laboratory setting can lead to unintentional chemical reactions and hazards. Furthermore, ensure that the regulator can handle the required flow rate. A mismatch here can lead to either a surplus or deficit of gas supply, further exacerbating efficiency problems. By focusing on these key compatibility factors, operators can enhance system reliability and achieve better pressure control, ultimately resulting in improved operational efficiency.

To ensure the long-term performance of your blanket gas regulator, regular maintenance is essential. Start by inspecting the regulator for any signs of wear or damage. Look for cracks or leaks in the body and check all connections to ensure they are secure. Regularly cleaning the regulator can help prevent buildup of contaminants that may affect its functionality. Utilizing a soft cloth and the appropriate cleaning solution can keep the regulator in good condition.

Another crucial aspect of maintenance is monitoring the pressure settings. Over time, the pressure may drift from the desired levels, affecting the performance of the equipment it serves. Make it a habit to check the pressure gauges frequently and recalibrate the regulator as needed. Additionally, replacing any worn-out seals or components promptly can prevent potential failures and extend the life of the regulator. Implementing these maintenance practices will help ensure that your blanket gas regulator functions optimally for years to come.