Leave Your Message

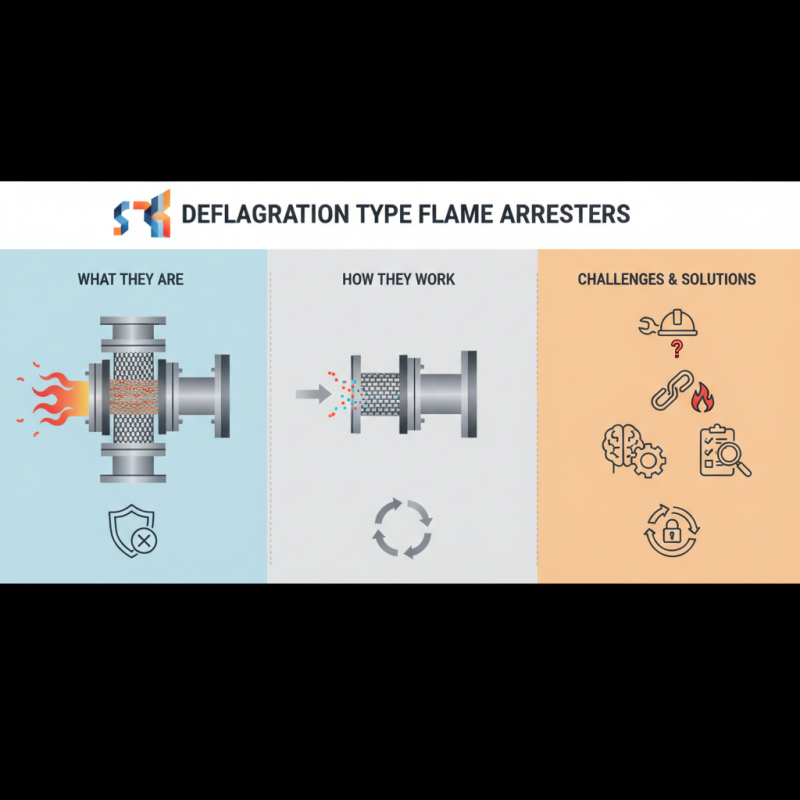

Deflagration Type Flame Arresters are crucial devices in the safety engineering landscape. These instruments help prevent flame propagation in gas and vapor processes. According to Dr. Emily Carter, a leading expert in fire prevention, "Deflagration Type Flame Arresters are vital for minimizing fire hazards in industrial applications."

These devices work by slowing down the combustion process. They do this through specific mechanisms that quench flames before they can travel through pipelines. Understanding how they operate is essential for industries handling flammable gases.

However, the industry faces challenges in ensuring the effectiveness of Deflagration Type Flame Arresters. Many systems may be installed incorrectly or inadequately maintained. Fire safety is not just about equipment, but also awareness. Continuous training and inspections can significantly enhance safety. While Deflagration Type Flame Arresters are essential, they are not foolproof. Regular reviews and updates to safety protocols are necessary.

Deflagration type flame arresters are vital safety devices in various industries. They prevent flames from traveling back into equipment and storage areas. In 2022, it was reported that flame arresters reduced explosion risks by over 30% in chemical plants. This significant decrease highlights their importance.

These devices work by cooling and dissipating the energy of the flame. They usually contain a series of metal mesh or plates that create turbulence. This turbulence slows down the flame front, effectively stopping it. A report from the National Fire Protection Association showed that proper installation could further increase safety measures by about 20%.

However, not all installations are perfect. Users often overlook maintenance, which can compromise effectiveness. Regular checks and replacements are necessary. While flame arresters are crucial, reliance on them without proper training can lead to dangerous situations. A lack of understanding in handling these devices can result in lapses in safety protocols. Identifying weaknesses in training is essential for improving workplace safety.

Deflagration type flame arresters play a crucial role in enhancing safety in industrial settings. These devices are engineered to prevent the propagation of flames from a pipeline or vessel into the surrounding environment. They work by cooling and quenching the flame front. This occurs when the flame passes through a series of closely spaced obstacles or screens, which encourage turbulence and heat dissipation.

According to industry data, flame arresters can reduce the risk of explosions by up to 90% when properly installed. This is particularly vital in sectors dealing with flammable gases and vapors. The effectiveness of a deflagration flame arrester hinges on its design and the specific flow characteristics of the gas it protects. However, not all installations meet stringent safety standards. Regular inspection and maintenance are necessary to ensure functionality.

Moreover, the operational principles involve the consideration of various gas types and their ignition properties. Each application can present unique challenges. For instance, the design parameters must match the gas’s specific energy release rate. Failure to do so could lead to catastrophic outcomes. Anecdotal evidence suggests that improper sizing or placement of these devices can severely compromise safety measures. This raises questions about compliance and industry practices. Addressing these issues is vital for advancing safety protocols.

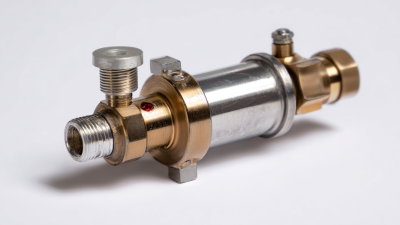

Deflagration type flame arresters are crucial safety devices. They prevent flames from traveling back into hazardous areas. Understanding their key components helps in selecting the right arresters for various applications.

One essential component is the flame mesh. This mesh absorbs heat from a flame. It creates a barrier that cools and extinguishes the flame. Materials like stainless steel or bronze are often used for durability. The materials must withstand high temperatures without degrading. This is critical for maintaining effectiveness.

Another important part is the housing. Many flame arresters have a robust metal housing. This protects internal components from damage. Some designs incorporate sight glass for easy monitoring. However, it's important to remember that even the best materials may fail. Regular inspections and maintenance are necessary to ensure reliability. This can reflect the user's commitment to safety.

| Component | Material | Function | Typical Applications |

|---|---|---|---|

| Housing | Carbon Steel, Stainless Steel | Provides structural integrity and containment | Chemical plants, oil & gas |

| Screen/element | Perforated Metal, Mesh | Prevents flame propagation while allowing gas flow | Storage tanks, fueling stations |

| Pressure Relief Valve | Brass, Stainless Steel | Ensures safe pressure levels | Pipelines, reactors |

| Flame Arresting Backing | Ceramic, Metal Alloy | Absorbs and mitigates heat | Industrial burners, boilers |

| Flame Detector | Silicon, Infrared Sensors | Monitors for flame presence | Safety systems, automation |

Deflagration type flame arresters are crucial in industries where flammable gases may be present. These devices prevent flames from traveling down pipelines. They work by cooling and dissipating heat while allowing gas flow. Effective design is vital for their performance.

Industry standards for flame arresters include rigorous testing protocols. These standards ensure reliability and safety in different environments. Testing evaluates the arrester's ability to stop flames at various pressures and temperatures. Factors like material durability and flow characteristics are carefully analyzed. Actual field conditions can be unpredictable, leading to potential challenges.

Moreover, discrepancies in test results may occur due to equipment variances. Sometimes, unanticipated variables may affect performance. Regular maintenance of flame arresters plays a critical role. Without proper upkeep, their effectiveness might diminish over time. Industries must continuously evaluate their systems to enhance safety measures.

This chart displays the performance of various deflagration type flame arresters under different testing scenarios. The data represents the maximum pressure drop (in mbar) measured during the deflagration test across various mediums.

Deflagration flame arresters are critical safety devices widely used across industries. They prevent the spread of flames and explosions in environments where flammable gases or vapors are present. In chemical manufacturing, for example, these devices can reduce the risk of catastrophic incidents. According to the National Fire Protection Association (NFPA), explosions in chemical plants account for approximately 10% of all fire-related incidents annually.

In the petroleum industry, deflagration flame arresters are essential for managing vapor emissions. These devices ensure that any ignition within a pipeline or tank doesn’t result in overwhelming damage. A recent report by the Oil and Gas Journal highlighted that proper installation of flame arresters can cut down vapor release incidents by nearly 30%. Such statistics emphasize the importance of integrating safety measures into everyday operations.

The food and beverage industry also utilizes these arresters. During processes like fermentation and distillation, there is a significant risk of explosive atmospheres. The International Society for Safety in the Chemical and Process Industry (ISCP) noted that many facilities have experienced near accidents. Continuous training and adherence to safety standards are crucial. Reflecting on these areas can lead to better practices and enhanced safety protocols over time.