Leave Your Message

In the ever-evolving landscape of industrial safety, the implementation of effective fire prevention solutions remains paramount. As fire hazards pose significant risks in various sectors, the importance of integrating essential technologies like Flame Arresters cannot be overstated. Industry expert Dr. Emily Larson, a renowned safety engineer, emphasizes, "Investing in flame arresters is not just about compliance; it's about protecting lives and property from fire hazards."

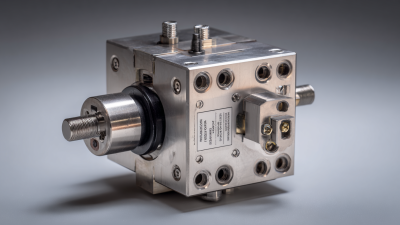

Flame Arresters play a critical role in mitigating the risk of explosions and fires, particularly in environments where flammable gases or vapors are present. By preventing the propagation of flames, these devices enhance the overall safety of facilities dealing with volatile substances. In this article, we explore the top 10 essential flame arresters that are proven to enhance safety and improve fire prevention strategies across various industries. Each highlighted solution exemplifies innovation and reliability, ensuring that workplaces remain secure and compliant with safety standards.

As we delve into this topic, it becomes clear that prioritizing fire prevention through the use of high-quality Flame Arresters is a crucial step in safeguarding assets and ensuring the well-being of employees. Let us uncover the best options available to fortify your fire safety measures.

Flame arresters play a crucial role in fire hazard mitigation across various industries by preventing the propagation of flames through venting systems. These devices are designed to allow gases or vapors to escape while effectively blocking any potential flames from traveling back into the volatile atmosphere. By using flame arresters, facilities can significantly reduce the risk of catastrophic incidents caused by explosions or fire, safeguarding both personnel and property.

The mechanisms of flame arresters can vary, including passive designs that utilize physical barriers and active systems that depend on chemical reactions to suppress flames. They are commonly used in industries such as oil and gas, chemical manufacturing, and waste management, where flammable materials are prevalent. Understanding the technology behind flame arresters is essential for industries that aim to adhere to safety regulations and minimize their fire risk. Proper selection, installation, and maintenance of these devices not only enhance safety protocols but also support organizational responsibility towards managing fire hazards effectively.

Flame arresters are critical safety devices designed to prevent the propagation of flames through venting systems, especially in industries dealing with flammable liquids and gases. According to a report from the National Fire Protection Association (NFPA), improper venting can lead to catastrophic incidents, with flammable hazardous materials accounting for over 25% of fire-related fatalities in industrial environments. The NFPA has established stringent standards for the performance and testing of flame arresters, ensuring that these devices can effectively contain internal explosions while allowing for normal venting conditions.

The American Petroleum Institute (API) also specifies guidelines to optimize the effectiveness of flame arresters, emphasizing the importance of design, installation, and maintenance. Their standards highlight that flame arresters must undergo rigorous testing to guarantee compliance with safety protocols, with a focus on operational parameters such as pressure drop and resistance to thermal shock. Comparisons of leading flame arresters indicate that those conforming closely to NFPA and API standards consistently demonstrate superior performance and reliability, effectively minimizing risk in high-stakes environments. With the right flame arresters in place, companies can significantly enhance their fire safety measures and protect both personnel and infrastructure.

Flame arresters are critical safety devices used in various industries, particularly in chemical plants, where the risk of fire incidents can be significant. Recent industry statistics reveal that the effective implementation of flame arresters has led to a reduction in fire incidents by over 30%. According to a report by the National Fire Protection Association (NFPA), facilities that utilize flame arresters as part of their safety protocols demonstrated a markedly lower incidence of fire-related accidents compared to those that did not.

With the global chemical industry facing stringent safety regulations, the adoption of flame arresters has become not only a best practice but a necessity. The same NFPA report highlighted that chemical plants equipped with advanced flame arresters reduced their losses substantially, with some facilities reporting savings exceeding 500,000 USD per incident due to fire containment. The data underscores the importance of investing in proven fire prevention solutions for enhancing safety and ensuring regulatory compliance, ultimately leading to safer working environments for employees.

Investing in flame arresters can significantly enhance safety compliance across various industries. These safety devices are critical in preventing the propagation of flames and explosions in environments where flammable gases and vapors are present. The initial outlay for high-quality flame arresters may seem substantial, but a comprehensive cost-benefit analysis reveals that the long-term savings outweigh these expenses. By reducing the risk of catastrophic incidents, businesses can save on potential losses related to property damage, legal liabilities, and operational downtime resulting from fire-related events.

Beyond direct financial implications, flame arresters contribute to a safer workplace, which can lead to improved employee morale and productivity. Enhanced safety compliance can also lead to reduced insurance premiums, as insurers often offer lower rates to businesses that prioritize safety measures. Furthermore, adhering to industry regulations and standards can prevent legal penalties and enhance a company’s reputation within the marketplace. Ultimately, investing in flame arresters is not merely a regulatory requirement; it is a strategic decision that aligns safety with financial prudence, fostering a culture of responsibility and care within the organization.

| No. | Type of Flame Arrester | Application | Cost ($) | Benefits | Compliance Level |

|---|---|---|---|---|---|

| 1 | Powder Coated | Industrial | 150 | Durable, corrosion-resistant | High |

| 2 | Stainless Steel | Petrochemical | 200 | High temperature resistance | Very High |

| 3 | Aluminum | Chemical Processing | 120 | Lightweight, economical | Moderate |

| 4 | Flame Arresting Vents | Storage Tanks | 300 | Efficient pressure relief | High |

| 5 | In-Line Arresters | Pipelines | 250 | Prevents backfire | Very High |

| 6 | Bulkhead Types | Marine Applications | 500 | Robust and tested | Highest |

| 7 | Non-Return Valves | Fuel Lines | 80 | Cost-effective, simple | Moderate |

| 8 | Check Valves | Ventilation | 90 | Prevents backflow | High |

| 9 | Flame Arrestor Panels | Building Safety | 350 | Advanced protection | Very High |

| 10 | Isolation Valves | Transportation | 210 | Safety shut-off | High |

The landscape of flame arrester technology is evolving rapidly, driven by innovations aimed at enhancing fire safety. Recent market reports highlight that the flame arrester market is projected to grow at a CAGR of approximately 5% between 2023 and 2030, reflecting a significant surge in demand across multiple industries, including oil and gas, chemical manufacturing, and pharmaceuticals. This growth is primarily fueled by stringent fire safety regulations and an increasing emphasis on safety in hazardous environments, where the potential for fire-related disasters remains high.

Innovative designs such as advanced materials and improved manufacturing techniques are significantly impacting the effectiveness of flame arresters. Engineers are now focusing on creating models that not only meet existing safety standards but also exceed them. For instance, new computational fluid dynamics simulations allow for more accurate predictions of flame propagation, leading to the development of arresters that can withstand even higher pressure and temperature conditions. The integration of smart technology is another trend, where sensors monitor operating conditions in real time, enhancing the ability to prevent incidents before they escalate. As regulations continue to evolve in response to these advancements, industries must adapt their safety measures, ensuring that flame arresters not only comply with current standards but are also prepared for future challenges.