Leave Your Message

In the industrial landscape, the effective management of gas pressure is vital for ensuring operational safety and efficiency, particularly in the chemical and oil industries. The Pilot Operated Nitrogen Blanket Gas Regulator plays a crucial role in maintaining a consistent pressure within storage vessels, thereby preventing oxidation and contamination of stored products. According to a report by the American Gas Association, improper gas regulation can lead to significant losses, with potential annual costs exceeding millions due to product spoilage and equipment damage. With the demand for nitrogen-based solutions projected to grow by 5% annually, selecting the right regulator has become increasingly important. This blog will explore five essential tips for choosing the right Pilot Operated Nitrogen Blanket Gas Regulator, ensuring you make informed decisions that enhance operational efficiency and safeguard your assets.

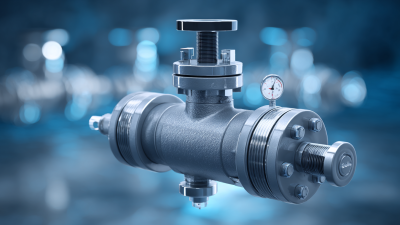

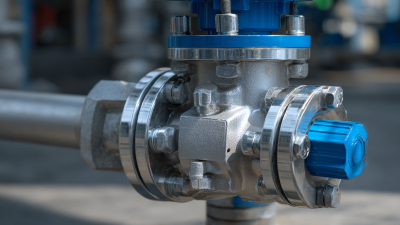

When selecting a pilot-operated nitrogen blanket gas regulator, understanding the specifications is crucial for ensuring optimal performance and safety in your operations. One of the key considerations is the pressure range of the regulator. It's essential to choose a model that can handle the specific pressures encountered in your system, which will not only maintain gas quality but also prevent equipment failure. Look for regulators designed to manage both low and high-pressure scenarios, as these can provide versatility in various applications.

Another important factor is the construction material of the regulator. Depending on the chemicals and environmental conditions in your settings, materials such as stainless steel or brass can offer better durability and resistance to corrosion. Additionally, ensure that the regulator features easy-to-read gauges for real-time pressure monitoring. This can enhance operational efficiency and safety by allowing quick adjustments based on system demands. By prioritizing these specifications, you can select a pilot-operated nitrogen blanket gas regulator that meets your unique requirements and enhances the stability of your gas supply system.

In industrial nitrogen systems, pressure regulation is crucial for maintaining safety and operational efficiency. The pressure within these systems must be controlled to prevent over-pressurization, which can lead to equipment failure, leaks, or even hazardous situations. A well-functioning pilot operated nitrogen blanket gas regulator is essential for achieving the accurate pressure levels needed for optimal system performance. By ensuring stable pressure, these regulators provide a protective gas blanket that helps to minimize oxidation and contamination of sensitive materials during storage and transportation.

Selecting the right pilot operated nitrogen blanket gas regulator not only safeguards the integrity of the industrial process but also enhances productivity. An appropriate regulator can adjust to fluctuations in input pressure and flow demands, ensuring that the operating environment remains consistent. This adaptability is particularly important in industries where precision is key, such as pharmaceuticals or food processing. Therefore, understanding the role of pressure regulation will enable organizations to make informed choices that improve reliability and efficiency in their nitrogen systems, ultimately contributing to their overall success.

| Tip Number | Tip Description | Importance | Considerations |

|---|---|---|---|

| 1 | Assess Flow Rate Requirements | Ensures sufficient gas supply for operational needs | Determine peak and average flow rates |

| 2 | Check Pressure Rating Compatibility | Prevents over-pressurization and system failures | Match regulator ratings with system specifications |

| 3 | Evaluate Temperature Range Operating Conditions | Ensures reliable operation under varying conditions | Consider ambient and process temperature ranges |

| 4 | Understand Maintenance Requirements | Reduces downtime and maintains efficiency | Select models with easy access for servicing |

| 5 | Consider Installation and Space Constraints | Facilitates effective integration in existing systems | Measure available space and configuration requirements |

When selecting a pilot-operated nitrogen blanket gas regulator, evaluating flow rates is crucial to ensure the efficient regulation of gases under varying conditions. The gas flow rate directly impacts system performance, particularly in applications involving volatile substances like ammonia, where effective gas dispersion is vital for safety. Recent studies highlight the necessity of assessing gas flow rates in relation to dispersion dynamics, especially on ammonia-fueled ships, which have shown regulatory gaps that could compromise safety during toxic release events.

Furthermore, industry reports suggest optimizing gas flow systems can significantly enhance operational efficacy. For instance, the assessment of various burner head geometries in gas stoves indicates that even minor adjustments in flow rates can lead to improved combustion efficiency and lower emissions. According to research, a well-tuned gas regulation system can result in a reduction of harmful emissions by up to 30%, showcasing the importance of integrating comprehensive flow evaluations into the selection process of gas regulators. This approach not only contributes to safety but also aligns with regulatory compliance and environmental sustainability goals.

When selecting a pilot operated nitrogen blanket gas regulator, one of the most crucial factors to consider is material compatibility. The choice of materials can significantly affect both the longevity and safety of the regulator. For instance, a study by the American Society of Mechanical Engineers (ASME) indicates that over 30% of regulatory failures in gas handling systems can be attributed to material incompatibility, leading to leaks and safety hazards. Utilizing materials that are resistant to corrosion and degradation, such as stainless steel or brass specifically designed for gas applications, can mitigate these risks and enhance the regulator's lifespan.

Moreover, the compatibility between the regulator and the specific gases being used cannot be overstated. The Gas Processors Association (GPA) emphasizes that the choice of elastomers and seals must align with the gas's chemical properties. For instance, certain rubber materials may deteriorate when exposed to nitrogen over extended periods, potentially resulting in catastrophic failures. According to data from the International Society of Automation (ISA), ensuring material compatibility can improve operational efficiency by up to 15%, highlighting the critical nature of this decision in the overall performance of nitrogen blanket systems. This careful consideration not only protects equipment but also supports compliance with safety regulations and standards within the industry.

When selecting a pilot-operated nitrogen blanket gas regulator, understanding the importance of industry standards and certifications is crucial. These standards define the safety, reliability, and efficiency required in the operation of pressure regulators, thereby minimizing risks associated with gas handling. Certifications from reputable organizations ensure that the regulator meets specific performance and safety benchmarks, which can significantly impact operational integrity. Moreover, selecting certified equipment can protect against legal liabilities that arise from non-compliance with industry regulations.

In addition to safety, the role of self-regulatory organizations (SROs) is also essential in the regulatory landscape. SROs typically develop and enforce standards tailored to specific industries, facilitating compliance and advancing best practices. The presence of such organizations in regulating equipment like gas regulators instills confidence in manufacturers and users alike, promoting a culture of accountability and continuous improvement within the industry. By adhering to these standards, operators can ensure optimal performance and safety in their applications, ultimately leading to greater efficiency and lower operational risks.

This chart represents the importance of various factors in choosing the right pilot operated nitrogen blanket gas regulator. The data illustrates the relative significance of each factor based on industry expert opinions.