Leave Your Message

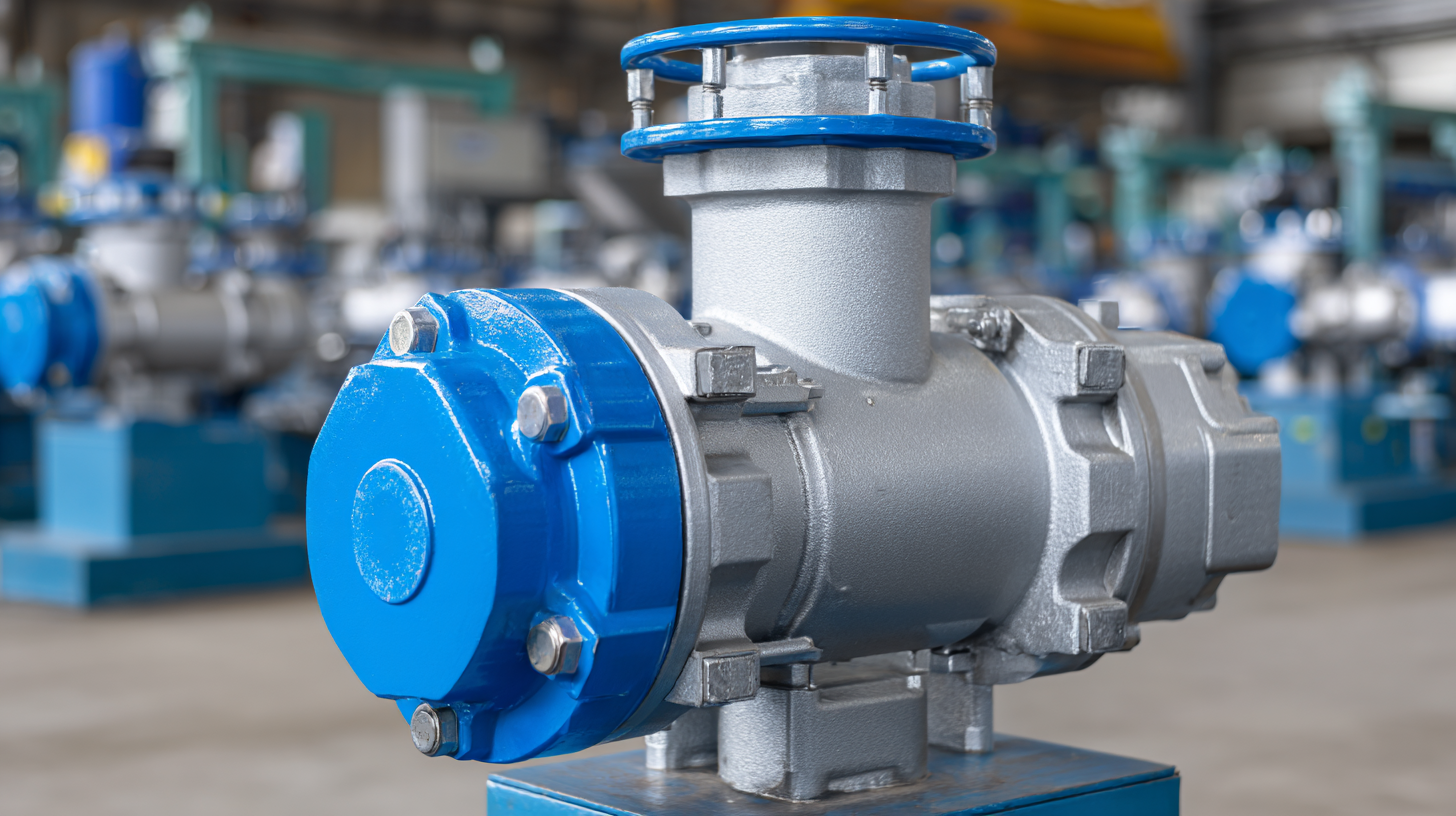

In today's industrial landscape, the significance of reliable Pressure Relief Valves (PRVs) cannot be overstated. According to a recent report by MarketsandMarkets, the global PRV market is projected to grow from USD 4.1 billion in 2021 to USD 5.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.2%. This growth is driven by increasing safety regulations across various sectors, such as oil and gas, water management, and manufacturing, where the integrity of pressure systems is paramount. Choosing the right PRV is essential for safeguarding equipment and ensuring operational efficiency. With the mantra "中国制造,全球共享,品质值得信赖," it is crucial to focus on quality and reliability when selecting these critical components, as they play a pivotal role in preventing pressure-related hazards. This blog will guide you through five essential tips for making an informed choice to enhance safety and performance in your operations.

When it comes to choosing the best pressure relief valve, understanding the importance of proper certification is paramount. The Pressure Equipment (Safety) Regulations 2016 lay out specific requirements that must be adhered to before pressure equipment can enter the Great Britain market. This includes ensuring that the pressure relief valves in question meet rigorous safety and performance standards. Certification acts as a guarantee that the product has undergone comprehensive testing, making it a critical factor in safeguarding against potential health and safety risks associated with incorrect installations, such as those seen with water heaters.

One essential tip in selecting the right pressure relief valve is to prioritize those that carry relevant certifications recognized in your region. Opting for certified valves not only ensures compliance with legal standards but also enhances the reliability of the equipment. Additionally, keep an eye on the market trends; with the global safety valve market expected to nearly double from USD 5.2 billion in 2025 to USD 11.87 billion by 2035, investing in certified and high-quality valves is a step toward future-proofing your projects while ensuring safety. Always conduct thorough research before making a purchase, as this can have significant implications for safety and efficiency in plumbing and heating applications.

When selecting a pressure relief valve (PRV), understanding key industry standards for certification is crucial. These standards ensure that the valves operate effectively and safely, relieving excess pressure in a system to prevent catastrophic failures. Organizations such as the American Society of Mechanical Engineers (ASME) provide guidelines for PRV design, testing, and maintenance, which are essential references for engineers and procurement teams.

One of the primary standards to consider is the ASME Section VIII for pressure vessels, which outlines specifications for the valves used in pressure relief applications. Additionally, the American National Standards Institute (ANSI) plays a significant role in establishing performance criteria. Familiarizing yourself with these standards not only guarantees compliance but also helps in choosing a reliable and durable valve that meets the operational needs of your system. Ensuring that your PRV conforms to recognized certifications will enhance safety, improve efficiency, and ultimately protect your investment in industrial processes.

Navigating international regulations for pressure relief valve imports and exports has become increasingly challenging, especially with the current uncertainties in global trade. As tariffs fluctuate and nations revise their trade policies, understanding how these elements impact pressure relief valve transactions is essential for companies looking to expand internationally. Businesses must stay informed about the latest tariff proposals and regulatory developments to ensure compliance and avoid unexpected costs.

Moreover, it’s crucial to strategically assess the potential impacts of tariffs on supply chain operations. By employing effective risk management strategies, companies can better navigate the complexities introduced by previous administrations' trade policies, including any potential returns to stringent tariffs. Companies should also focus on optimizing their operations within foreign-trade zones, which can offer relief from certain tariff burdens while allowing for seamless cross-border transactions. As the global landscape evolves, proactive adaptation to these trade dynamics will be key to sustaining competitiveness in the pressure relief valve market.

When selecting a pressure relief valve, ensuring compliance with safety standards is crucial for both equipment integrity and personnel safety. One of the first steps in this process is to familiarize yourself with the relevant regulations such as ASME, ISO, and API. These standards provide essential guidelines that help manufacturers and users alike understand the minimum safety requirements needed to operate safely under pressure. Engaging with these standards not only enhances the safety of your operations but also protects your investment by ensuring that your equipment meets industry benchmarks.

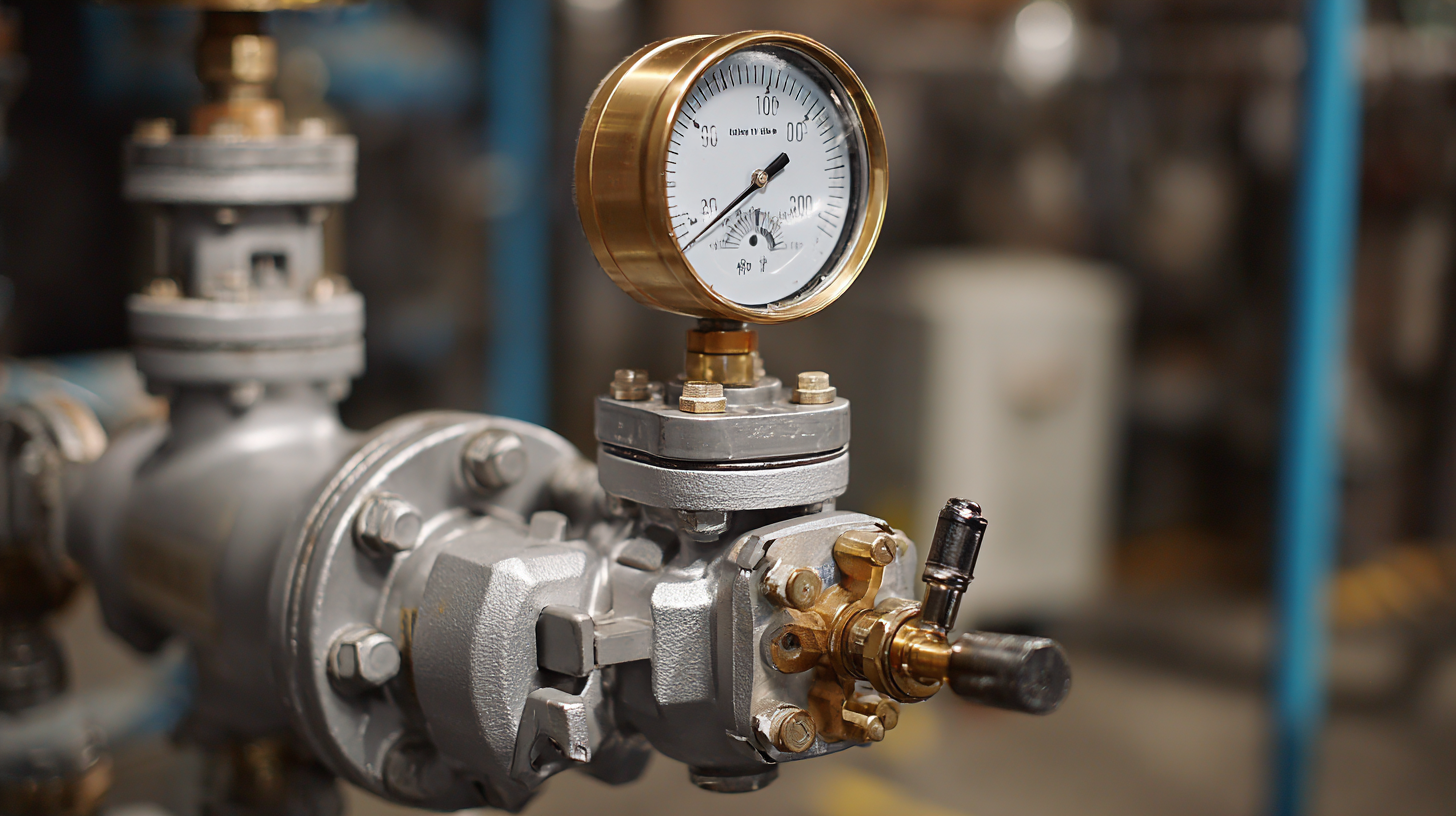

Another important aspect of compliance is the proper selection and installation of the pressure relief valve itself. It's essential to choose a valve that is adequately sized for your specific application, as this will ensure it functions optimally under varying pressure conditions. Additionally, the valve must be installed in accordance with the manufacturer's guidelines and regulatory standards to prevent malfunctions. Regular inspections and maintenance are also necessary to keep the valve functional and compliant over time. By prioritizing these elements, you can ensure that your pressure relief system meets safety standards effectively, thereby safeguarding both personnel and processes.

| Tip Number | Tip Description | Compliance Standard | Installation Requirement |

|---|---|---|---|

| 1 | Determine the set pressure based on system requirements | ASME Section VIII | Properly sized to the system |

| 2 | Select a suitable valve material for the application | API 520 | Material compatibility with media |

| 3 | Check the Flow Rate to ensure adequate performance | NFPA 70 | Installation position consideration |

| 4 | Ensure proper sizing to prevent overpressure | ISO 4126 | Minimum and maximum pressure evaluations |

| 5 | Regular maintenance and testing for reliability | OSHA 29 CFR 1910 | Routine inspection schedule |

When selecting pressure relief valves, understanding the role of certification bodies is critical for ensuring compliance and safety in operations. Certification bodies not only verify that these valves meet established standards but also ensure that manufacturers adhere to necessary regulations before placing their products in various markets, such as Great Britain. These requirements are outlined in safety regulations like the Pressure Equipment (Safety) Regulations, which help maintain safety across industries utilizing pressure equipment.

In an industry projected to hit a market value of nearly USD 21 billion by 2034, compliance with safety standards is paramount. Certification processes encompass everything from type approval test specifications to regular audits, providing a structured framework for manufacturers. These standards are crucial not just for market access, but for customer trust and product reliability. The assurance that a pressure relief valve meets rigorous safety and performance criteria can be the defining factor for consumers when choosing the best product for their needs.