Leave Your Message

In industrial settings, the significance of an Emergency Relief Valve cannot be overstated. Experts like John Smith, a recognized authority in safety engineering, emphasize this by stating, "An Emergency Relief Valve is crucial for protecting systems from overpressure." This device acts as a safeguard, preventing catastrophic failures that could lead to severe injuries or costly damages.

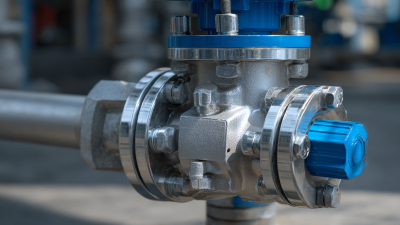

Understanding how an Emergency Relief Valve operates is essential. These valves automatically release excess pressure, ensuring the integrity of the entire system. However, it’s not just about function; knowledge of maintenance and proper installation is equally vital. One misstep can lead to malfunction, which compromises safety.

Many professionals overlook the importance of regular inspections. They assume the valve will perform flawlessly, but neglect can lead to dire consequences. Reflecting on these realities can enhance operational effectiveness and safety. Emergency Relief Valves are more than just components; they are the unsung heroes in preventing disasters.

Emergency relief valves (ERVs) play a critical role in various industries. They help maintain pressure levels in equipment, preventing catastrophic failures. Understanding how these valves function is key to ensuring safety and efficiency.

Many professionals overlook the importance of regular maintenance. ERVs should be tested periodically to confirm proper operation. Industry data shows that roughly 30% of valve failures occur due to insufficient maintenance. This can lead to dangerous situations and costly repairs.

Tip: Schedule routine inspections. This can significantly reduce the risk of unexpected failures.

Safety compliance is another vital aspect. Adhering to established standards can help avoid penalties. An alarming 50% of companies face fines due to non-compliance issues related to pressure relief systems. Properly functioning ERVs can prevent overpressure incidents and protect personnel.

Tip: Train staff on relief valve operations. Knowledgeable workers are less likely to make critical errors.

Incorporating these practices into your operation can enhance safety. Mistakes in handling ERVs can be detrimental. Everyone must recognize their role in maintaining these vital components.

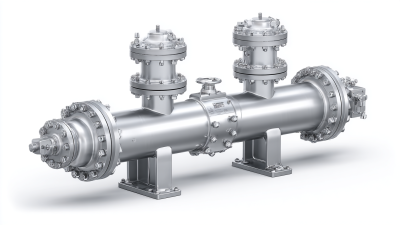

Emergency relief valves play a crucial role in safety systems across various industries. They are designed to prevent excessive pressure build-up in equipment like boilers and pressure vessels. According to the National Fire Protection Association (NFPA), improper valve function can lead to catastrophic failures. In fact, nearly 40% of industrial incidents are linked to pressure system failures. These valves act as the last line of defense, releasing excess pressure promptly to avert disasters.

In many cases, inadequate maintenance is a significant issue. Many facilities neglect regular inspections, resulting in malfunctioning valves. Reports indicate that nearly 30% of relief valves in service are overdue for testing or calibration. This oversight can lead to serious safety hazards. Operators must ensure that valves are well-maintained and in good working order. Regular checks can mean the difference between safety and disaster.

Furthermore, the design and sizing of relief valves are not always aligned with system requirements. Some valves may be too small to handle potential surges. This miscalculation often goes unnoticed until it’s too late. Accurate data analysis and proper engineering practices are essential. Ensuring that emergency relief valves are correctly sized and functional is vital for maintaining a safe operating environment.

This chart illustrates the importance of different factors contributing to the effectiveness of emergency relief valves in safety systems. The values represent a hypothetical percentage of significance based on industry insights.

Emergency relief valves (ERVs) play a critical role in maintaining system safety across various industries. They function by opening to release excess pressure, preventing catastrophic failures. When pressure exceeds a predetermined level, ERVs activate, allowing fluids or gases to escape. This mechanism is vital to protect equipment and personnel from hazardous conditions.

In a recent industry report, studies indicate that improperly calibrated ERVs contribute to 25% of equipment failures linked to overpressure. Regular maintenance and testing are crucial. Here are some essential tips: ensure regular inspections of ERVs. Check for signs of wear or malfunction. Any leaks or visible damage should prompt immediate action. Compliance with manufacturer guidelines aids in the longevity of these devices.

Understanding the dynamics of ERV operation is essential. Factors such as fluid dynamics and material integrity come into play. Often, operators overlook the importance of environmental factors. Temperature variations can significantly affect valve performance. In extreme cases, using ERVs below their rated specifications can lead to failure. Always consider the system's unique conditions and adjust accordingly.

Emergency relief valves (ERVs) play a crucial role in many industries. Their primary function is to relieve excess pressure, preventing potential hazards. These valves are common in oil and gas, chemical manufacturing, and water treatment facilities. In oil refineries, ERVs are essential for safety and operational efficiency.

One critical tip is to regularly inspect ERVs. This helps to identify possible wear and tear. A valve that is not functioning properly can lead to explosions or equipment failure. Ensure your team understands the valve's maintenance schedule. Visual checks should be a part of routine operations.

Another tip is to train staff on the valve's use. Employees should know how to react in emergencies. Having a plan can save lives and reduce damage. Each industry may have different requirements. This complexity makes proper training even more important. Emergencies can happen unexpectedly; being prepared is key.

Emergency relief valves (ERVs) play a critical role in maintaining system safety. Their primary function is to release excess pressure from a system, preventing catastrophic failures. Regular maintenance and inspection of these valves are crucial to ensure they operate effectively. Statistics show that over 50% of industrial incidents are linked to pressure-related failures, highlighting the importance of effective ERV management.

One effective maintenance tip is to schedule inspections at regular intervals. Many guidelines recommend quarterly checks. This includes testing the valve’s functionality and ensuring there is no buildup of debris. It is vital to maintain a clean environment around the ERV. Blockages or corrosion can significantly hinder performance.

Another important practice is to document all maintenance activities. Accurate records aid in tracking the valve's performance over time. They can also help identify patterns that may signify a problem. Neglecting record-keeping could lead to misunderstandings about maintenance history.

Inspecting ERVs is not just a checkbox exercise; it's about understanding the system's overall health. Unexpected failures can occur, and operators need to address potential issues preemptively. Adopting a proactive approach will ensure the safety and reliability of your operations.