Leave Your Message

In the world of industrial safety, a Flame Arrestor is a critical component. It helps prevent the propagation of flames in gas and vapor systems. According to Dr. Jane Smith, a leading expert in fire safety technology, "A Flame Arrestor is essential for avoiding catastrophic incidents." This statement underscores its importance in protecting both lives and property.

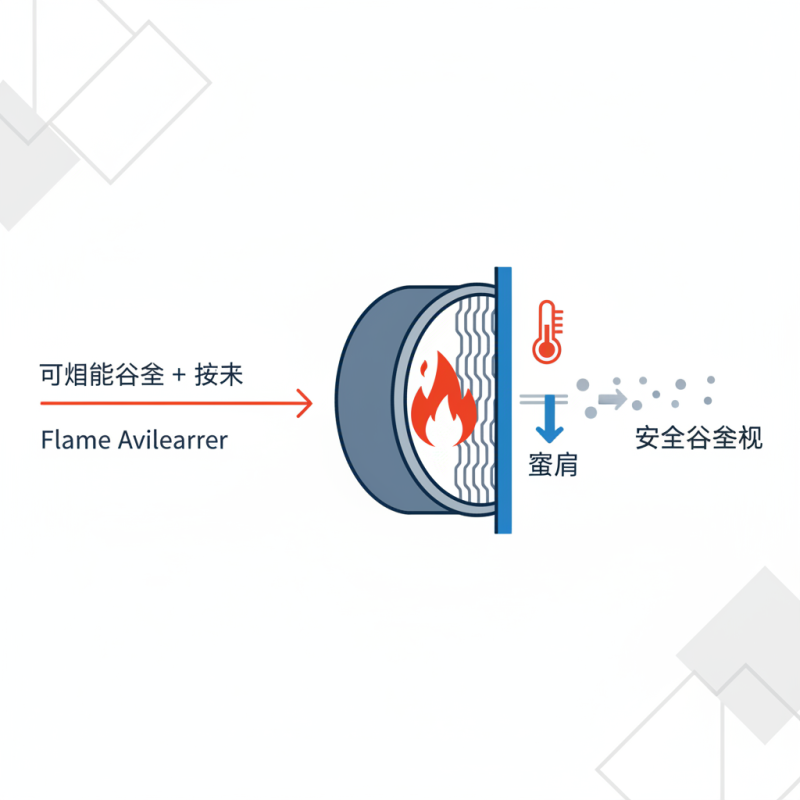

Flame Arrestors work by employing a simple yet effective mechanism. They allow gas to pass through while blocking the flame. When combustible gases ignite, the Flame Arrestor cools the flame front. This process can significantly reduce risks in various industries, such as oil and gas. Nevertheless, the effectiveness of these devices depends on correct installation and maintenance.

Despite the advancements in technology, misconceptions about Flame Arrestors persist. Some people may think that they offer absolute protection. However, these devices need regular inspections and replacements. When neglected, they can fail to function properly in critical moments. Awareness and education about their role are essential in minimizing hazards.

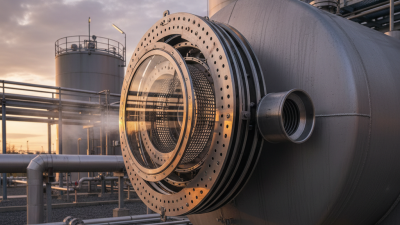

A flame arrestor plays a crucial role in industrial safety. It prevents the propagation of flames in systems that handle flammable gases and liquids. When a volatile substance ignites, the flame arrestor acts as a barrier. The device cools the gas and limits the flame's energy. This reduces the risk of explosion and protects both workers and equipment.

According to the National Fire Protection Association (NFPA), flame arrestors have been instrumental in reducing workplace incidents. In industries like chemical manufacturing and oil refining, proper installation can decrease explosion risks by over 60%. Visual evidence shows that sites with flame arrestors experience fewer fire-related incidents. However, improper maintenance poses a challenge.

Industry experts emphasize the importance of regular inspections. A malfunctioning flame arrestor can lead to catastrophic failures. In fact, a report by the Center for Chemical Process Safety highlights that nearly 40% of incidents stem from equipment failure. These statistics remind us to prioritize device integrity. Flame arrestors are vital, but they require diligence to ensure safety.

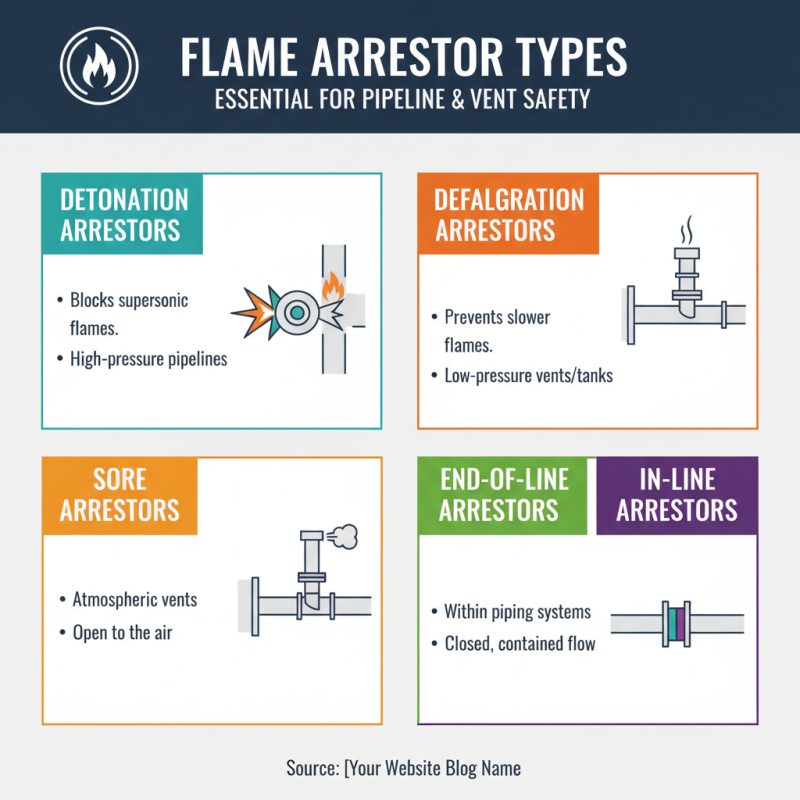

Flame arrestors play a crucial role in safety by preventing flames from traveling through pipelines or vents. They come in various types, tailored for different applications and conditions. Understanding these types is essential for effective safety measures.

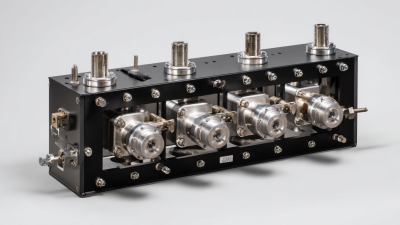

One common type is the passive flame arrestor. It uses a mesh or baffle to cool and extinguish flames. In contrast, active flame arrestors rely on sensors and control systems. They activate in response to fire conditions, providing an extra layer of protection.

Tips: Regularly inspect flame arrestors to ensure they are functioning properly. Check for any signs of wear or damage.

Choosing the right flame arrestor can be challenging. Factors include temperature, pressure, and the specific gas involved. Miscalculations can lead to serious hazards.

Tips: Engage with experts when selecting a flame arrestor. Their experience can help avoid costly mistakes.

Ultimately, the correct installation of flame arrestors matters greatly. Improper installation can negate their protective features. Address any concerns thoroughly to enhance safety measures.

Flame arrestors are crucial devices designed to prevent fires and explosions in various settings. They work by allowing gas to flow while blocking flames from traveling back into the source. This mechanism relies on a series of barriers and passages that cool and quench flames. When a flame attempts to move back through the device, it encounters these obstacles, which reduce its energy and extinguish it.

Tips: Regularly check the condition of flame arrestors. Look for signs of wear or blockages. Keeping the device clean can ensure efficient operation.

The design of a flame arrestor varies based on its application. Some models use mesh screens or ceramic materials, while others incorporate specific geometries. Maintaining proper airflow is essential. An improperly sized device may fail under certain conditions. Regular inspections are beneficial.

Tips: Always consult guidelines for installation. Correct placement is crucial for functionality. Understand the specific needs of your environment to select the right type.

This bar chart illustrates the efficiency of different types of flame arrestors in preventing fire and explosion. The types represented include Metal Mesh, Perforated Plate, Flame Screen, and Ceramic Foam, each with varying levels of effectiveness.

Flame arrestors play a crucial role in industrial safety. They prevent flames from spreading through pipes or tanks. Adhering to industry standards is essential for their design and functionality. Various organizations establish these standards to ensure safety and reliability.

One significant standard is the National Fire Protection Association (NFPA) guidelines. These guidelines outline essential requirements for flame arrestors. Manufacturers must consider these criteria to ensure effective performance. Other standards from organizations like the American National Standards Institute (ANSI) are also relevant. They provide specifications for materials, testing methods, and installation procedures.

Compliance with such standards is not just a formality. It is a measure of safety. However, some designs may fall short. For instance, improper installation can lead to failures. Regular assessments are vital. Facilities must reevaluate their systems and update designs accordingly. Balancing innovation with compliance can be challenging but necessary for user safety.

Flame arrestors are essential in many industries to prevent explosions from rapidly spreading. Regular maintenance is crucial for their effective operation. According to a study by the National Fire Protection Association, neglecting these components increases the risk of accidents by over over 30%.

Inspecting flame arrestors should happen at regular intervals. Check for any visible signs of wear, corrosion, or blockages. The frequency of these inspections can depend on the environment and the materials being handled. In harsher settings, more frequent checks are advisable.