Leave Your Message

In the industrial sector, ensuring safety during the handling of flammable gases and liquids is paramount. According to a 2020 report by the National Fire Protection Association, incidents related to gas explosions account for approximately 20% of all industrial fires, underscoring the critical need for effective flame control solutions.

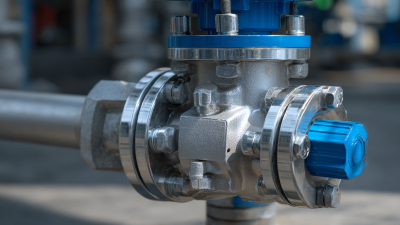

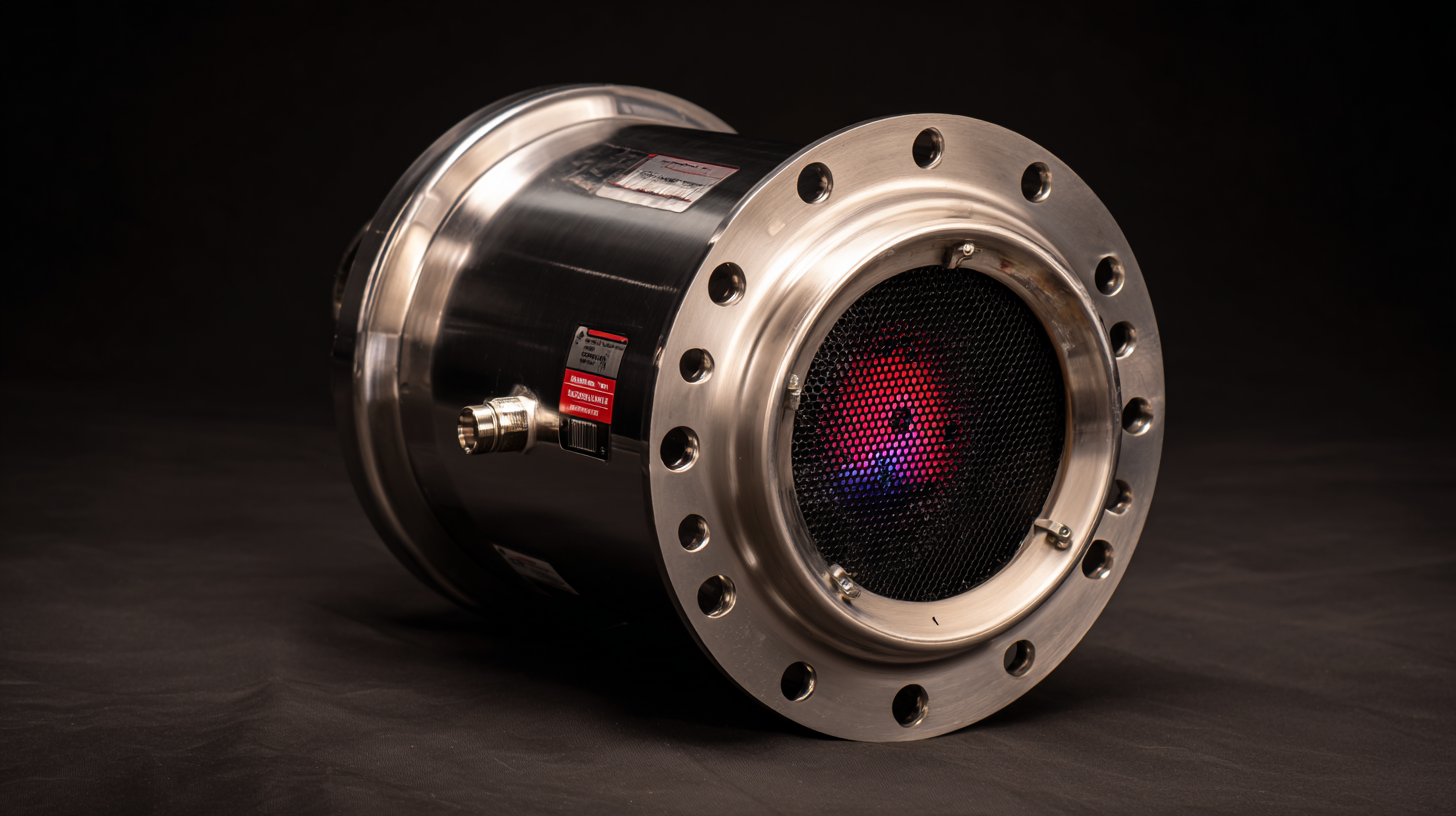

One such solution, the Inline Flame Arrestor, plays a vital role in preventing flames from propagating along pipelines, safeguarding both personnel and equipment. This device operates by absorbing heat and quenching flames, thus preventing the threat of explosions. As industries adapt to evolving safety regulations and standards, the selection of the right Inline Flame Arrestor becomes crucial. This guide aims to navigate the complexities of choosing an appropriate Inline Flame Arrestor tailored to specific operational needs, ensuring optimal safety and compliance in hazardous environments.

One such solution, the Inline Flame Arrestor, plays a vital role in preventing flames from propagating along pipelines, safeguarding both personnel and equipment. This device operates by absorbing heat and quenching flames, thus preventing the threat of explosions. As industries adapt to evolving safety regulations and standards, the selection of the right Inline Flame Arrestor becomes crucial. This guide aims to navigate the complexities of choosing an appropriate Inline Flame Arrestor tailored to specific operational needs, ensuring optimal safety and compliance in hazardous environments.

When operating in hazardous environments, understanding the functionality and significance of inline flame arrestors becomes crucial. These specialized devices are designed to prevent flame propagation within piping systems by absorbing and dissipating heat from a developing flame. Their effectiveness hinges on the specific application and the materials being transported. Choosing the right flame arrestor ensures safety and compliance with industry regulations, making it an essential investment for any facility handling flammable substances.

**Tip 1:** Assess the operational environment carefully. Consider factors such as temperature, pressure, and the type of gases or liquids present. This assessment will help you select a flame arrestor that offers the best protection for your specific situation.

**Tip 2:** Regular maintenance is paramount. Schedule routine inspections and cleanings of your flame arrestors to ensure they function correctly and to extend their lifespan. Neglecting these aspects can lead to catastrophic failures in case of an emergency.

Understanding these aspects of inline flame arrestors will empower you to make informed decisions that enhance safety in your operations.

| Type of Inline Flame Arrestor | Material | Max Operating Pressure (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Standard Flame Arrestor | Stainless Steel | 150 | -40 to 150 | Chemical Processing |

| High-Pressure Flame Arrestor | Carbon Steel | 300 | -20 to 200 | Oil & Gas |

| Corrosive Environment Flame Arrestor | Hastelloy | 150 | -40 to 180 | Pharmaceuticals |

| Low-Pressure Flame Arrestor | Aluminum | 50 | -40 to 140 | Ventilation Systems |

When selecting an inline flame arrestor, understanding key industry standards and regulations is crucial for ensuring safety and compliance. One of the primary standards is the National Fire Protection Association (NFPA) 30, which outlines guidelines for flammable and combustible liquids. Adhering to these guidelines can significantly reduce the risk of fire hazards in industrial settings. According to the NFPA, improper installation or selection of flame arrestors can lead to a 30% increase in the likelihood of catastrophic incidents involving flammable vapor ignition.

Additionally, the American National Standards Institute (ANSI) provides specifications that manufacturers must meet to ensure optimal performance of flame arrestors. For instance, ANSI/API 2000 sets the standards for venting pressure relief and allows for pressure build-up during operational processes. As highlighted in a recent report by the Industrial Safety and Health Administration (ISHA), 70% of industrial accidents involving flammable substances were linked to non-compliance with these standards. Therefore, selecting a flame arrestor that conforms to ANSI/APIs guidelines is essential in mitigating risks and protecting personnel and equipment.

When selecting an inline flame arrestor, evaluating material compatibility is crucial for optimal performance. According to the American Petroleum Institute (API), compatibility with the operating environment can significantly affect the longevity and reliability of flame arrestors. For instance, materials like stainless steel and aluminum are often preferred due to their resistance to corrosion and high temperatures, making them suitable for various applications in the petrochemical sector. Reports indicate that improper material selection can lead to premature failure or even dangerous incidents, emphasizing the need for careful consideration.

Performance metrics are equally vital in ensuring the effectiveness of inline flame arrestors. The National Fire Protection Association (NFPA) guidelines suggest evaluating the minimum extinction ratio (MER) – a critical measure that indicates the device's ability to prevent flames from propagating. Devices should meet a minimum MER of 0.3 for effective performance in gas service, while liquid applications may require more stringent standards. Moreover, flow rates and pressure drops should also be assessed; a study by the Compressed Gas Association reveals that a properly rated flame arrestor can maintain flow efficiency without compromising safety, reinforcing the need for precise evaluations in the selection process.

This bar chart illustrates the maximum operating temperatures of various materials used in inline flame arrestors. It helps in evaluating which material type would be the most suitable based on performance metrics.

When choosing an inline flame arrestor, understanding the impact of flow rate and pressure drop is crucial for ensuring optimal efficiency. The flow rate indicates the volume of gas or vapor passing through the arrestor, while the pressure drop refers to the loss of pressure as the gas flows through the device. Selecting a flame arrestor that accommodates the specific flow rate of your system can significantly enhance its performance, preventing potential hazards.

Tips: Always consult the manufacturer's specifications to determine the recommended flow rates for different models of flame arrestors. It’s essential to assess your process requirements and make adjustments accordingly to avoid bottlenecks or excessive pressure losses that could compromise safety.

Additionally, monitor pressure drop closely during operation. A significant increase may suggest blockages or inefficiencies in the system that require immediate attention. Regular maintenance and inspections can help sustain optimal performance, ensuring that your inline flame arrestor functions effectively under varying conditions. Stay proactive in addressing any changes in flow rates to maintain safety and efficiency in your operation.

When selecting an inline flame arrestor, it's crucial to understand the different types available and their specific applications across various industries.

Standard inline arrestors are designed for low-pressure systems and are commonly utilized in chemical processing plants. Their compact design allows for easy installation within piping systems while ensuring maximum safety. On the other hand, high-temperature versions are better suited for industries handling extreme heat, such as oil and gas.

Tip: Always assess the environmental conditions and chemical compatibility when choosing a flame arrestor to ensure optimum performance and longevity.

Applications in the automotive and pharmaceutical industries require specialized flame arrestors that can withstand unique challenges.

Automotive applications might benefit from catalytic arrestors, which not only prevent flames but also assist in reducing emissions.

Meanwhile, the pharmaceutical industry often opts for stainless steel arrestors that maintain cleanliness and resist contamination.

Tip: Consider consulting with industry experts to identify the most effective flame arrestor for your specific operational needs and regulatory compliance.