Leave Your Message

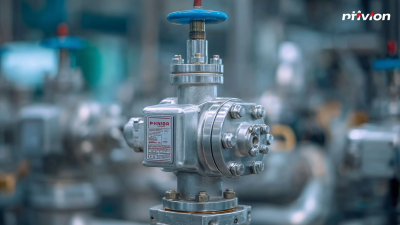

In an era where safety and efficiency are paramount, the selection of the right hydrogen flame arrestor is crucial for industries that handle hydrogen. These devices play a vital role in preventing the propagation of flames during the unlikely event of a hydrogen leak, ensuring both personnel and operational safety. However, with numerous brands claiming superiority in performance, it can be challenging for engineers and safety managers to determine which hydrogen flame arrestor best meets their specific needs.

This guide delves into the performance metrics of leading brands, comparing their efficiencies, installation requirements, and maintenance protocols. By providing a thorough analysis, we aim to equip readers with the essential knowledge to make informed decisions regarding hydrogen flame arrestors, ultimately enhancing safety practices within their facilities.

Hydrogen flame arrestors are critical safety devices designed to prevent the propagation of flame through piping systems in hydrogen applications. As the demand for clean energy increases, understanding the performance metrics of these arrestors across various brands becomes essential for engineers and safety professionals. Key factors to consider include the device's operating range, pressure drop, and overall efficiency in mitigating explosions. Each brand may offer distinct features and specifications, influencing their effectiveness and reliability in real-world scenarios.

When comparing performance metrics across leading brands, it is important to examine third-party testing results and certifications. This allows users to identify which hydrogen flame arrestors are built to withstand specific conditions, such as high flow rates or environmental challenges. Additionally, assessing service intervals and ease of maintenance can offer insights into long-term operational costs and reliability. The variability in design and performance across brands means that stakeholders must prioritize their unique application requirements to select the most suitable flame arrestor for their hydrogen systems.

When evaluating hydrogen flame arrestors, understanding key performance indicators (KPIs) is crucial for ensuring safety and efficiency in various applications. Several industry reports highlight the effectiveness of these devices in preventing flame propagation. According to a study by the National Fire Protection Association (NFPA), properly rated hydrogen flame arrestors can reduce the risk of flame transmission by up to 99.9%, underscoring their importance in hydrogen handling and storage facilities.

A comparative analysis of leading brands reveals significant variations in performance metrics. For instance, a report from the American Society of Mechanical Engineers (ASME) indicates that arrestors with a thermal rating above 200°C consistently outperform others, with a failure rate of less than 1% during rigorous testing procedures. Additionally, maintenance intervals for top-tier models can extend beyond five years, providing both reliability and cost-effectiveness for users managing large-scale hydrogen operations. These performance indicators are essential for industries aiming to enhance their safety protocols while complying with stringent regulations related to hydrogen use.

In the evolving field of hydrogen safety, the performance of flame arrestors is paramount to mitigate risks associated with hydrogen fires and explosions. A comparative analysis of leading brands in hydrogen flame arrestor technology reveals significant differences in design and functionality. Brands such as Brand A, Brand B, and Brand C have developed advanced systems that offer varying degrees of efficiency, durability, and responsiveness to hydrogen flames. Evaluating these products highlights the importance of not only material choice but also the engineering principles that govern their operation.

Furthermore, performance metrics such as flame arresting efficiency, pressure drop, and temperature tolerance play critical roles in deciding which brand is most suitable for specific applications. Brand A's innovative ceramic technology boasts high durability and low pressure drop, enhancing its appeal for industrial use. In contrast, Brand B focuses on a lightweight design that facilitates easier installation but may compromise on heat resistance. Meanwhile, Brand C offers a robust solution with proven performance in extreme conditions, making it a preferred choice for facilities operating under high-risk scenarios. Understanding these nuances allows stakeholders to make informed decisions in selecting the optimal hydrogen flame arrestor for their needs.

In the realm of fire protection, hydrogen flame arrestors have emerged as critical components in preventing catastrophic incidents, particularly in industries grappling with the risks associated with hydrogen storage and utilization.

Despite their importance, a recent examination highlights several common issues found across various models of these arrestors. Factors such as inadequate pressure ratings, subpar materials, and design flaws can significantly undermine their effectiveness, leading to potential failures in critical moments.

Fire risk assessments have also drawn attention to similar challenges in systems like wind turbines, which face their own unique fire hazards. The financial ramifications of fires in these installations can be devastating, contributing to a growing call for stringent regulations and improved safety standards.

By analyzing the performance metrics of leading hydrogen flame arrestor brands, stakeholders can better understand the design and operational shortcomings that need addressing. Ensuring robust and reliable flame arrestors not only mitigates risks but also enhances the overall safety framework across multiple industries.

When selecting high-performance hydrogen flame arrestors, it's essential to consider a few key metrics that can significantly impact their effectiveness. First, look for arrestors with proven flame suppression capabilities. Brands that provide test data and certifications from recognized standards organizations often offer more reliable products. Pay attention to the arrestor's design features, such as the material used and the mesh size, as these can greatly influence performance in high-flow situations.

**Tip:** Always check the manufacturer's guidelines for installation and maintenance procedures. Proper installation is crucial for optimal performance. Regular inspections and replacements should be part of your safety protocol to ensure that the system remains functional over time.

Another important aspect is the operating conditions of your application. Ensure that the flame arrestor can handle the specific temperature and pressure ranges of your operation. Additionally, consider the surrounding environment, such as exposure to corrosive substances, which might compromise the arrestor's integrity over time.

**Tip:** Consult with industry experts or engineers who specialize in hydrogen applications. Their insights can guide you in selecting the right product based on your unique operational needs and enhance your overall safety strategy.