Leave Your Message

In today's increasingly competitive manufacturing landscape, optimizing operational efficiency is paramount. The Vacuum Sequence Valve technology has emerged as a critical component in enhancing system performance across various industrial applications. According to a recent report by MarketsandMarkets, the global vacuum systems market is projected to reach $7.3 billion by 2025, driven by the rising demand for automation and precision in manufacturing processes. These valves are essential in controlling the sequence of vacuum applications, minimizing downtime, and improving energy consumption by up to 30%. Implementing effective strategies for leveraging Vacuum Sequence Valve technology not only streamlines production workflows but also drives significant cost savings and sustainability efforts. This blog will provide five essential tips to maximize efficiency through the intelligent use of Vacuum Sequence Valves, ensuring that your operations remain at the forefront of industry innovation.

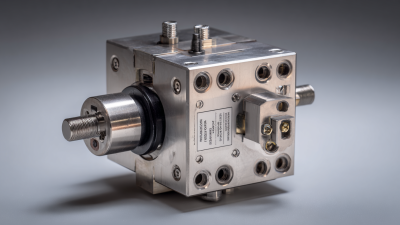

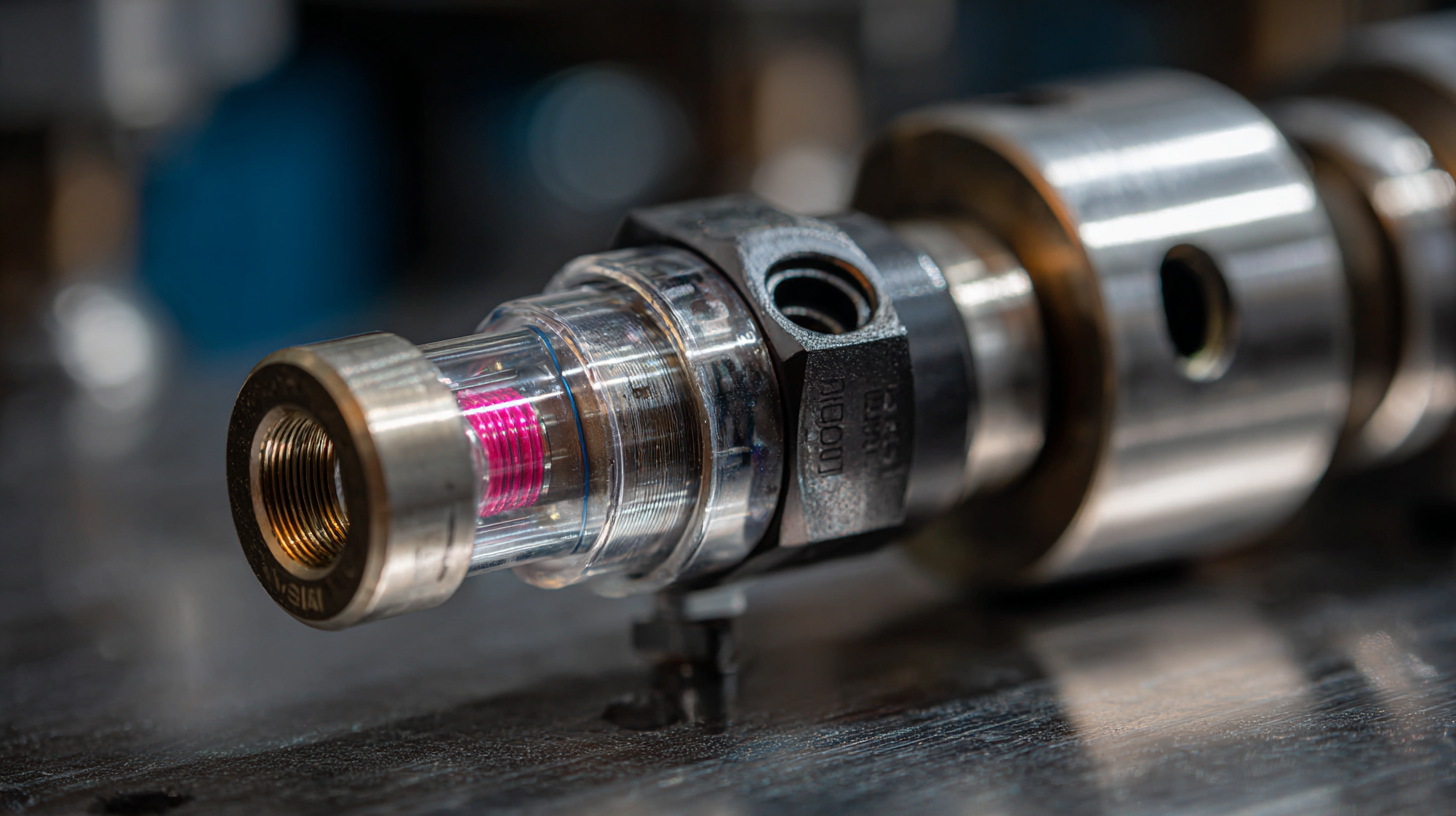

Vacuum sequence valve technology plays a crucial role in various industrial processes, particularly in applications like chemical vapor deposition (CVD). Understanding the fundamentals of this technology is essential for optimizing efficiency and performance. At its core, a vacuum sequence valve regulates the flow of gases in a system, allowing for precise control during operations that require specific atmospheric conditions. By mastering these basics, operators can anticipate potential issues and implement strategies to mitigate them, enhancing overall system reliability.

Moreover, addressing vacuum system performance problems can significantly impact production efficiency. As seen in various industrial sectors, such as manufacturing or material coating processes, the proper function of each component—especially those involving complex mechanisms like converging-diverging steam jets—is vital. Regular maintenance and a solid understanding of vacuum system dynamics can help prevent malfunctions. By concentrating on these foundational aspects of vacuum sequence valve technology, industries can improve their operational effectiveness while reducing downtime, ultimately leading to better product quality and lower costs.

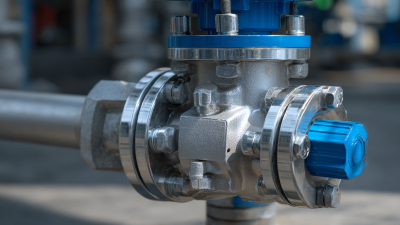

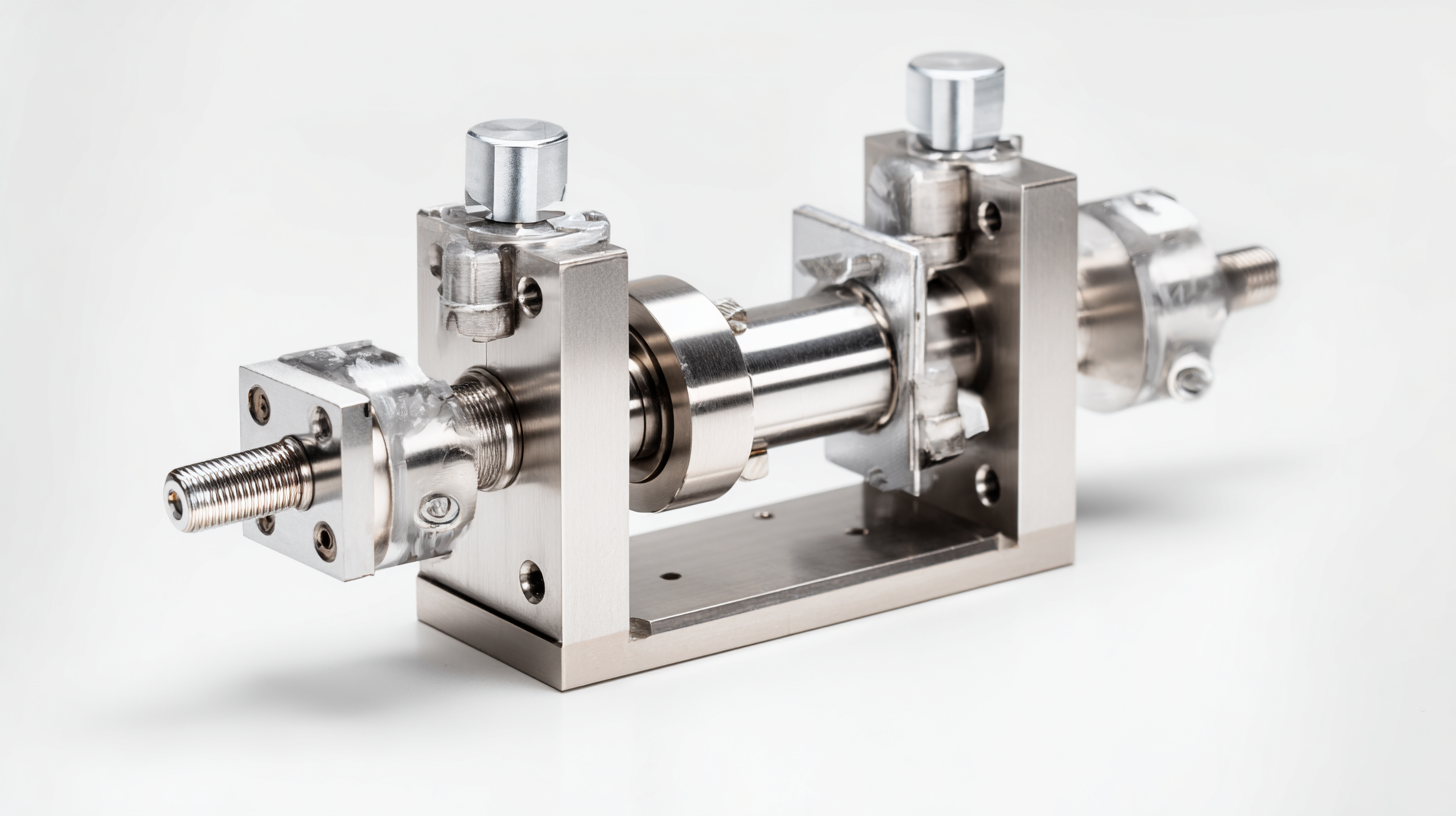

Optimizing system design is crucial for enhancing efficiency when integrating vacuum sequence valve technology. A well-thought-out design not only improves performance but also minimizes energy consumption and operational costs. Begin by assessing the specific requirements of your application, which will inform the selection of appropriate valves and their arrangement within the system. By strategically positioning valves to streamline airflow and reduce unnecessary resistance, you can significantly enhance the overall efficiency of your vacuum system.

Moreover, incorporating automation into your design can lead to even greater efficiency gains. Automated control systems can adjust valve operation based on real-time feedback, ensuring optimal performance under varying conditions. This not only maximizes the effectiveness of the vacuum sequence valves but also extends their lifespan by preventing unnecessary wear and tear. Additionally, regular maintenance schedules should be integrated into the system design from the outset, as this proactive approach helps maintain high efficiency levels throughout the operational lifespan of the equipment.

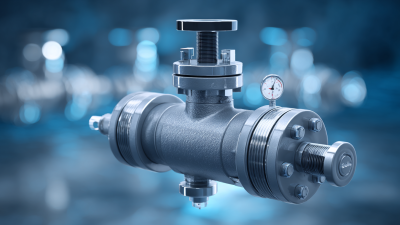

The longevity and performance of vacuum sequence valves are heavily influenced by regular maintenance practices. According to the American Society of Mechanical Engineers (ASME), effective preventive maintenance can extend the lifespan of such valves by up to 30%. This is critical, as a well-maintained valve system not only operates more efficiently but also reduces the risk of costly breakdowns. Routine checks for wear and tear, as well as ensuring that seals and gaskets are in good condition, can lead to significant operational savings. Data from the Valve Manufacturers Association (VMA) indicates that a mere 10% improvement in valve reliability can enhance overall system efficiency by approximately 7%.

Incorporating a structured maintenance schedule that includes cleaning the valve components, inspecting for obstructions, and performing performance tests can significantly impact operational outcomes. A report from the International Journal of Pressure Vessels and Piping suggests that regularly serviced valves have an average failure rate that is 50% lower than those that are neglected. This emphasizes the necessity of not only establishing a rigorous maintenance routine but also adhering to manufacturer specifications to ensure optimal functioning. By prioritizing preventive measures, industries can enjoy not just enhanced efficiency but also longer valve life and reduced operational costs.

Integrating automation into vacuum sequence valve technology is crucial for enhancing overall performance and operational efficiency. Automation streamlines the control processes associated with vacuum systems, reducing the risk of human error and ensuring consistent operation. By implementing programmable logic controllers (PLCs) or advanced software solutions, manufacturers can set precise timing and sequencing of valves, optimizing the entire vacuum cycle. This not only enhances throughput but also minimizes downtime, leading to a more efficient production process.

Moreover, automation allows for real-time monitoring and diagnostics of the vacuum systems. With smart sensors and IoT integration, operators can gather valuable data on system performance, quickly identifying any irregularities that may arise. This proactive approach to maintenance ensures that any issues are addressed before they result in significant production delays. By integrating automation, companies can achieve not only improved efficiency but also a higher level of reliability in their operations, ultimately driving better business outcomes.

This chart illustrates the significant improvement in efficiency achieved through the integration of automation in Vacuum Sequence Valve Technology. The data shows a rise from 60% efficiency before automation to 90% after implementing automated systems.

When dealing with vacuum systems, troubleshooting common issues is critical to maintaining efficiency and performance. One of the most prevalent problems is inconsistent vacuum pressure, which can be caused by leaks in the system. Regularly inspecting all connections and seals for wear can help preemptively tackle this issue. Additionally, using a vacuum gauge can assist in monitoring pressure levels and identifying anomalies early.

Another common concern involves the vacuum sequence valve itself. If the valve is not operating correctly, it can lead to improper sequencing and disrupted processes. Cleaning the valve periodically and ensuring that it is free from debris can dramatically enhance its functionality. Moreover, ensure that the actuator is in good condition and calibrated properly to guarantee the system operates as intended.

Lastly, operator training cannot be overlooked. A well-informed team can spot issues that might go unnoticed otherwise. Regular training sessions on the vacuum system and its components ensure that operators understand how to troubleshoot effectively, leading to quicker problem resolution and less downtime. By following these tips and addressing common issues head-on, you can maximize the efficiency of your vacuum systems reliably.

| Tip Number | Tip Description | Common Issues | Troubleshooting Steps |

|---|---|---|---|

| 1 | Regular Maintenance Checks | Leakage in valves | Inspect seals and connections for any wear and tear. |

| 2 | Calibration of Sensors | Inaccurate pressure readings | Perform sensor calibration according to manufacturer’s specifications. |

| 3 | Optimize System Design | Inefficient flow paths | Redesign flow paths to minimize bends and obstruction. |

| 4 | Use Quality Components | Frequent component failures | Replace low-quality components with high-grade alternatives. |

| 5 | Implement Control Systems | Lack of automation | Install automation controls to enhance efficiency and response times. |