Leave Your Message

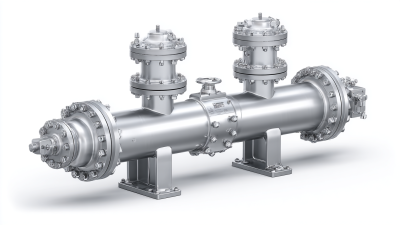

In the realm of modern industries, the pilot-operated diaphragm valve stands out as a pivotal component in fluid control systems. This specialized valve operates with exceptional precision to regulate the flow of liquids and gases, making it an essential choice for applications requiring reliable and efficient operation.

Understanding the functionality of pilot-operated diaphragm valves not only sheds light on their intricate design and operational mechanics but also highlights their myriad benefits, such as enhanced safety, reduced maintenance, and improved control of flow rates.

As industries continue to evolve, embracing advanced technologies that promote efficiency and sustainability, the pilot-operated diaphragm valve emerges as a key player, driving innovation while ensuring optimal performance in various applications.

This article will guide you through the essential aspects of these valves, illustrating their significance and operational advantages in today’s industrial landscape.

Pilot-operated diaphragm valves are essential components in modern industrial applications, providing a reliable solution for controlling the flow of fluids and gases. These valves utilize a separate pilot system that regulates the diaphragm's movement, offering precise control over varying pressure levels. According to a report by Grand View Research, the global diaphragm valve market is expected to reach USD 5.56 billion by 2025, underscoring the increasing demand for these innovative solutions across various sectors, including pharmaceuticals, water treatment, and food processing.

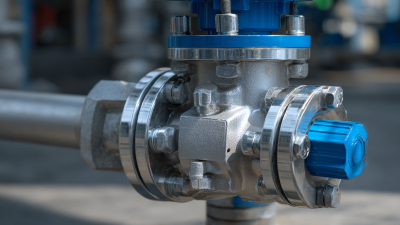

One of the key functional features of pilot-operated diaphragm valves is their ability to efficiently manage high-pressure differentials while maintaining leak-free operation. This is particularly beneficial in industries where contamination is a critical concern. A study published in the Journal of Chemical Technology & Biotechnology found that diaphragm valves significantly reduced the risk of leakage compared to traditional valve types, enhancing safety and operational integrity. By employing materials resistant to corrosive and abrasive substances, pilot-operated diaphragm valves further enhance their longevity and reliability, making them a preferred choice for industries requiring stringent adherence to safety standards.

Pilot-operated diaphragm valves are essential components in modern industrial applications, offering a range of efficiency metrics and performance data that highlight their advantages. One of the primary benefits is their ability to regulate flow with remarkable precision, which can lead to optimized processes and significant energy savings. These valves utilize a pilot pressure to control the diaphragm's movement, resulting in reduced wear and tear and longer service life compared to traditional valves.

When considering the adoption of pilot-operated diaphragm valves, it’s important to assess their impact on system efficiency. These valves often operate with lower pressure drops, enhancing the overall productivity of fluid systems. Additionally, they provide quicker response times, facilitating better control in dynamic applications.

**Tip:** Regular maintenance and periodic checks are crucial to ensure these valves function optimally. By maintaining appropriate operating conditions and promptly addressing any leaks or mechanical issues, industries can extend the lifespan of their pilot-operated diaphragm valves and maximize their operational efficiency.

In conclusion, the performance data collected from pilot-operated diaphragm valves indicates that they not only improve efficiency metrics but also contribute to substantial cost savings over time. Their versatility makes them suitable for a variety of applications, ensuring that industries can achieve reliable performance across diverse environments.

This chart illustrates the efficiency metrics and performance data of pilot-operated diaphragm valves across various applications in modern industries.

Pilot-operated diaphragm valves have emerged as essential components in modern process automation, particularly when contrasting with conventional valves. Unlike traditional valves that rely solely on mechanical means for operation, pilot-operated valves utilize a pressure differential to control flow, offering enhanced accuracy and efficiency. According to a recent industry report by the International Society of Automation, these valves can improve operational reliability by up to 30% compared to their conventional counterparts.

One of the critical advantages of pilot-operated diaphragm valves is their superior control over fluid dynamics, which reduces the chances of overpressure and minimizes wear. In high-stakes environments, such as chemical plants or water treatment facilities, the ability to finely adjust flow rates is crucial. The report highlights that using pilot-operated valves can enhance overall system efficiency by 20%, leading to lower energy consumption and reduced long-term maintenance costs.

**Tip:** When selecting valves for your process automation system, consider the specific demands of your application. Analyzing parameters such as pressure, temperature, and fluid characteristics can lead to more informed decisions and greater operational effectiveness. Transitioning to pilot-operated valves may significantly reduce downtime and improve safety, especially in dynamic industrial environments.

| Feature | Pilot-operated Diaphragm Valves | Conventional Valves |

|---|---|---|

| Operation method | Uses pilot pressure to control flow | Mechanically actuated |

| Response time | Fast response due to pilot control | Slower response, dependent on actuator |

| Leakage | Typically low leakage | Higher leakage potential |

| Maintenance | Less frequent maintenance required | More regular maintenance needed |

| Cost | Higher initial investment | Lower initial costs |

| Applications | Complex process control | Standard valve applications |

Pilot-operated diaphragm valves are increasingly recognized for their pivotal role in enhancing safety and control across various industries. These valves are particularly useful in applications such as chemical processing, water treatment, and food manufacturing, where precise control over fluid flow is essential. According to the Global Market Insights report, the pilot-operated valve market is projected to grow at a rate of 6.5% annually through 2030, driven by the need for improved safety measures and operational efficiency.

One of the key benefits of pilot-operated diaphragm valves is their ability to regulate flow and pressure with high precision, minimizing the risk of leaks and ensuring safe operation. The American Society of Mechanical Engineers (ASME) highlights that nearly 75% of industrial accidents are caused by fluid leakage, underscoring the importance of reliable valve systems. By utilizing pilot-operated diaphragm valves, industries can reduce the likelihood of hazardous incidents and maintain a safer working environment.

Tip: When selecting pilot-operated diaphragm valves, it's crucial to consider the specific pressure and temperature ratings of your application. This ensures optimal performance and longevity of the valve. Additionally, regular maintenance checks can further enhance safety by identifying wear and tear before they lead to potential failures.

Pilot-operated diaphragm valves are becoming increasingly popular in various industries due to their exceptional efficiency and reliability. A key consideration for businesses when adopting this technology is the cost analysis, particularly concerning long-term savings and return on investment (ROI). According to a recent report from the Flow Control Industry Association, companies can see a reduction in overall operational costs by as much as 25% when integrating pilot-operated diaphragm valves, thanks to their precise control and lower energy consumption.

Additionally, these valves contribute to significant maintenance savings. A study published by the Valve Manufacturers Association indicated that maintenance costs for traditional valve systems can be reduced by up to 40% when switching to pilot-operated designs. The longevity and reduced wear on components not only extend the life of the valve systems but also minimize downtime, allowing for better resource allocation within the plant. With the upfront investment often recouped within the first few years of implementation, the transition to pilot-operated diaphragm valves offers a compelling case for modern industries aiming for efficiency and cost-effectiveness.