Leave Your Message

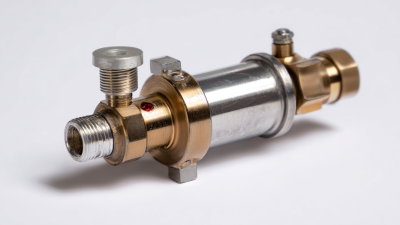

In the realm of industrial applications, maintaining product integrity and operational efficiency is paramount. One innovative solution to achieve these objectives is the use of the Pilot Operated Nitrogen Blanket Gas Regulator. This specialized device plays a crucial role in regulating the flow of nitrogen gas, creating an inert atmosphere that protects sensitive materials from oxidation and contamination. By understanding the benefits of incorporating this regulator into operations, industries can enhance their processes, reduce wastage, and prolong the shelf life of their products. This guide aims to provide a comprehensive overview of how to effectively implement and utilize Pilot Operated Nitrogen Blanket Gas Regulators, highlighting their operational advantages and the positive impact they can have on various industrial sectors.

In the realm of industrial applications, maintaining product integrity and operational efficiency is paramount. One innovative solution to achieve these objectives is the use of the Pilot Operated Nitrogen Blanket Gas Regulator. This specialized device plays a crucial role in regulating the flow of nitrogen gas, creating an inert atmosphere that protects sensitive materials from oxidation and contamination. By understanding the benefits of incorporating this regulator into operations, industries can enhance their processes, reduce wastage, and prolong the shelf life of their products. This guide aims to provide a comprehensive overview of how to effectively implement and utilize Pilot Operated Nitrogen Blanket Gas Regulators, highlighting their operational advantages and the positive impact they can have on various industrial sectors.

Pilot-operated nitrogen blanket gas regulators play a critical role in minimizing emissions within industrial settings. These regulators work by maintaining a constant pressure in storage tanks while utilizing nitrogen as a protective blanket. This process significantly reduces the risk of vapor loss, which is essential for industries that handle volatile substances. By efficiently regulating the internal environment of storage tanks, these systems effectively contain harmful emissions, leading to a cleaner and safer operational footprint.

In addition to their emission-reducing capabilities, pilot-operated nitrogen blanket gas regulators contribute to enhanced efficiency and safety. By preventing the exposure of volatile liquids to atmospheric pressure fluctuations, these systems ensure stability in production processes. They not only protect the integrity of the stored materials but also reduce the likelihood of accidents associated with gas releases. Consequently, industries can achieve compliance with stringent environmental regulations while simultaneously improving their operational efficiency and safeguarding their personnel. The integration of these regulators represents a proactive step towards sustainable industrial practices.

Nitrogen blanketing is an essential process in industrial applications, particularly in environments dealing with volatile substances. By creating an inert atmosphere, nitrogen blanket gas regulators help prevent the formation of explosive mixtures that could result from exposing flammable liquids or gases to air. This is crucial in industries such as chemical manufacturing, oil refining, and food processing, where safety is paramount. The use of pilot operated nitrogen blanket gas regulators enhances the effectiveness of this process by ensuring precise control over the nitrogen levels, thus maintaining optimum safety conditions.

In hazardous environments, even minor lapses in safety can lead to catastrophic consequences. The implementation of nitrogen blanketing not only mitigates the risk of explosions but also minimizes oxidation and reduces the potential for product degradation. Pilot operated gas regulators are designed to respond quickly to changes in pressure and flow, thereby providing a reliable safety net in challenging conditions. By maintaining a controlled and consistent nitrogen atmosphere, these regulators play a pivotal role in safeguarding both personnel and assets while enhancing overall operational efficiency.

This chart illustrates the impact of nitrogen blanketing on process safety in various industrial applications. The data highlights the reduction in incident probabilities associated with hazardous environments when utilizing pilot operated nitrogen blanket gas regulators.

Pilot operated nitrogen blanket gas regulators offer significant cost efficiency in industrial applications by optimizing gas management systems. These regulators maintain a consistent pressure within gas storage tanks, minimizing the risk of gas loss and reducing the frequency of system adjustments. By ensuring the nitrogen blanket remains intact, they help to prevent oxidation and contamination of stored materials, which is essential for maintaining product quality and extending the lifespan of equipment.

Furthermore, the design of pilot operated regulators allows for precise control over gas flow, which reduces energy consumption and enhances overall operational efficiency. With lower operational costs, businesses can allocate resources more effectively, enabling investments in other critical areas of production. This efficiency not only translates to immediate cost savings but also contributes to sustainable practices by lowering waste and emissions associated with over-pressurization and gas leakage, making pilot operated nitrogen blanket gas regulators a wise choice for industrial applications.

| Application Area | Cost Savings (%) | Efficiency Gain (%) | Maintenance Reduction (%) | Gas Consumption Reduction (%) |

|---|---|---|---|---|

| Oil and Gas Production | 15 | 20 | 25 | 10 |

| Chemical Manufacturing | 12 | 18 | 30 | 8 |

| Food and Beverage Industry | 10 | 15 | 20 | 5 |

| Pharmaceuticals | 14 | 22 | 18 | 9 |

| Metals and Mining | 16 | 19 | 35 | 12 |

In industrial operations, particularly within steam power plants, the implementation of nitrogen blanketing through pilot operated gas regulators proves to be crucial for enhancing operational reliability. Nitrogen blanketing serves as a protective layer that minimizes the exposure of equipment to oxygen and moisture, which are primary contributors to corrosion. By maintaining a controlled atmosphere around critical components, this method significantly extends the lifespan of machinery and reduces maintenance intervals, thus leading to improved overall efficiency.

In industrial operations, particularly within steam power plants, the implementation of nitrogen blanketing through pilot operated gas regulators proves to be crucial for enhancing operational reliability. Nitrogen blanketing serves as a protective layer that minimizes the exposure of equipment to oxygen and moisture, which are primary contributors to corrosion. By maintaining a controlled atmosphere around critical components, this method significantly extends the lifespan of machinery and reduces maintenance intervals, thus leading to improved overall efficiency.

As industries prepare for the inevitability of cycling operations, the benefits of nitrogen blanketing become even more pronounced. The reduction of equipment wear and tear can mitigate the costs associated with frequent maintenance and unexpected downtime. Advanced corrosion protection methods, such as film-forming technologies, complement the use of nitrogen blanketing by providing an additional barrier against corrosive agents. This integrated approach not only enhances equipment longevity but also supports a more sustainable operational environment, positioning plants to better manage the challenges posed by cycling conditions.

In industrial applications, the ability to monitor and control gas pressure in real time has become paramount. Advanced pilot-operated nitrogen blanket gas regulators utilize sophisticated technology that ensures stable gas flow, which enhances process efficiency. By providing continuous feedback on pressure levels, these regulators enable operators to make immediate adjustments, reducing the risk of overpressure or underpressure situations that can compromise system integrity. This real-time monitoring capability significantly minimizes downtime and optimizes resource use.

Tips: When selecting a gas regulator, consider one with integrated sensors for improved data accuracy. Regular maintenance and calibration of these devices are also essential to ensure they perform optimally and effectively respond to varying operational demands.

Implementing advanced gas regulation technology not only streamlines operational processes but also enhances safety protocols. The ability to predict and react to fluctuations in gas supply aids in preventing potential hazards, fostering a safer working environment. With the right tools in place, industrial facilities can achieve greater reliability and efficiency in their operations.

Tips: Always train staff on the proper use and troubleshooting techniques for gas regulators to ensure quick responses during abnormal pressure events. Consider regular training sessions to keep all personnel informed of the latest safety standards and technology updates.