Leave Your Message

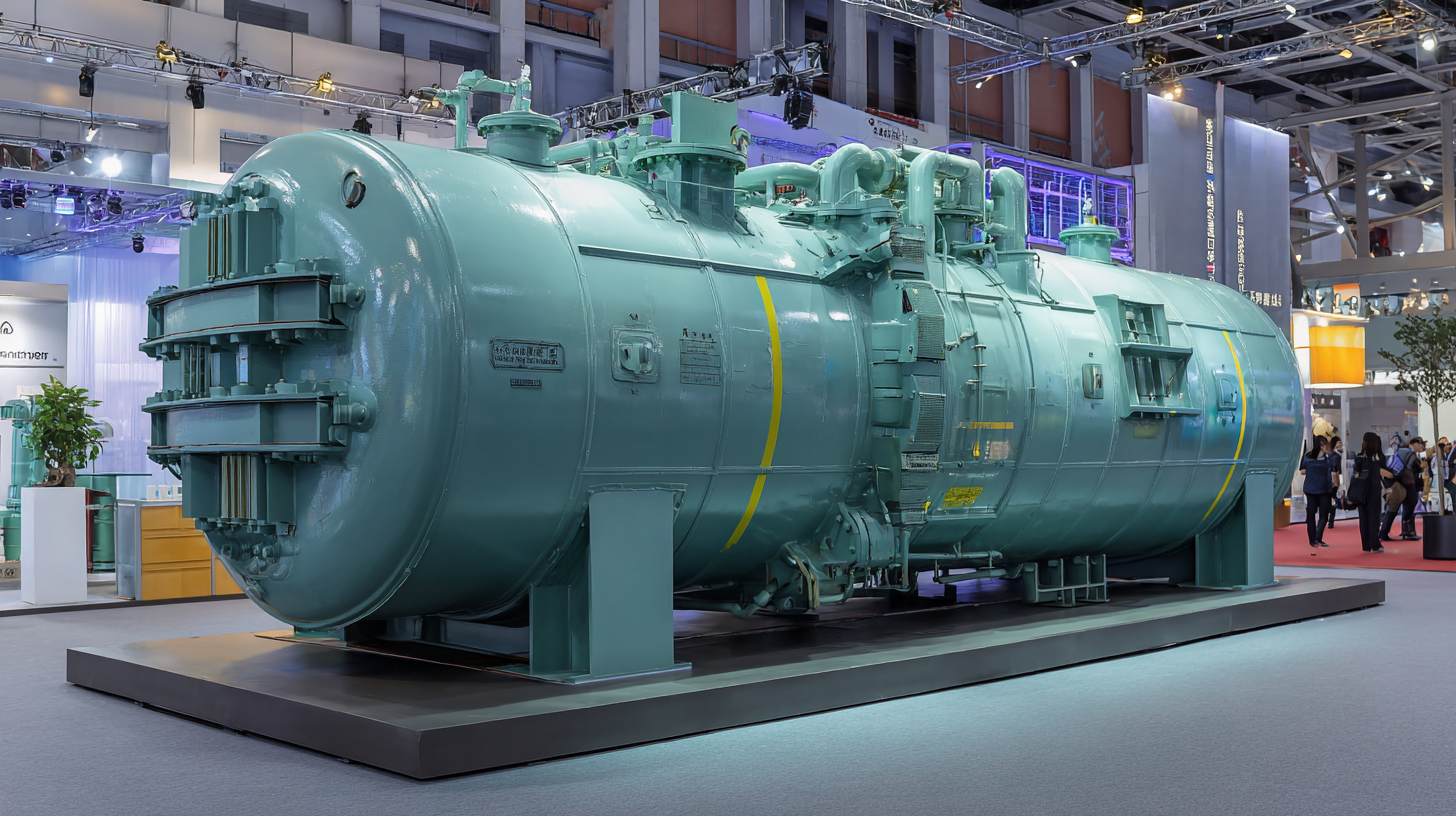

The 138th China Import and Export Fair, set to take place in 2025, presents a pivotal opportunity to explore advancements in industrial safety, particularly through the use of Tank Flame Arrestors. These critical safety devices play a significant role in preventing the propagation of flames within tanks containing flammable liquids, thereby protecting both personnel and property from catastrophic incidents. As the fair showcases cutting-edge technologies and innovations, the introduction of Tank Flame Arrestors is expected to draw considerable attention from industry professionals seeking to enhance operational safety. This introduction aims to highlight the importance of these devices in modern industrial applications, emphasizing their effectiveness in mitigating fire hazards and compliance with safety regulations. As the fair approaches, discussions surrounding Tank Flame Arrestors will become increasingly relevant, underpinning the broader narrative of safety and innovation within the context of global trade and commerce.

Flame arrestors play a crucial role in industrial safety measures, particularly in high-risk environments such as biogas plants and the oil and gas industry. These devices are designed to prevent the propagation of flames and explosions, serving as a vital line of defense against fires that can arise from various operational hazards. In biogas plants, where flammable gases are produced from organic waste, the implementation of flame arrestors is essential for safeguarding personnel and equipment from potential ignition events. By aligning with international standards and best practices in fire risk management, these measures significantly enhance the safety profile of renewable energy operations.

Similarly, the use of flame arrestors in the oil and gas sector is increasingly critical due to the volatile nature of the materials handled. As companies aim to meet robust safety and environmental protection requirements, flame arrestors provide an effective solution for mitigating fire risks associated with equipment and processes. The emphasis on these safety devices highlights the industry's commitment to maintaining a secure working environment while minimizing the potential for catastrophic incidents. By integrating advanced flame arrestor technology, industries can reinforce their safety measures and ensure compliance with evolving regulatory standards.

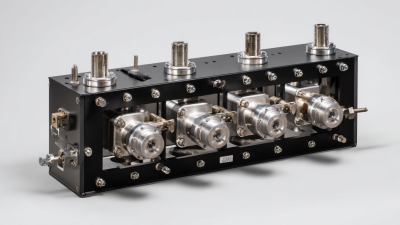

Recent advancements in tank flame arrestor technology have significantly contributed to enhancing safety measures in industrial settings, particularly at events such as the 138th China Import and Export Fair in 2025. With the increasing complexity of storage systems, modern flame arrestors are designed to prevent the spread of flame or explosion while allowing the safe venting of gases. Innovations such as improved material compositions, failure analysis techniques, and smart monitoring systems have made these devices more reliable and efficient.

Recent advancements in tank flame arrestor technology have significantly contributed to enhancing safety measures in industrial settings, particularly at events such as the 138th China Import and Export Fair in 2025. With the increasing complexity of storage systems, modern flame arrestors are designed to prevent the spread of flame or explosion while allowing the safe venting of gases. Innovations such as improved material compositions, failure analysis techniques, and smart monitoring systems have made these devices more reliable and efficient.

Tip: When selecting a flame arrestor for your application, consider the specific type of fuel being stored, as different materials may have distinct ignition characteristics.

Furthermore, automated diagnostics and real-time data monitoring are at the forefront of flame arrestor development. These technologies allow for proactive maintenance and immediate responsiveness to potential safety hazards, ensuring that flame arrestors function effectively under all conditions. The integration of these innovations into safety protocols at major events will be critical to minimizing risks associated with fuel storage.

Tip: Regular training on the latest safety measures, including proper usage and maintenance of flame arrestors, can greatly reduce the likelihood of incidents.

The regulatory landscape for flame arrestors in China is critical for enhancing safety in industrial operations, especially during large events like the China Import and Export Fair. Flame arrestors play a vital role in preventing explosive flames from propagating through piping systems, thereby reducing the risk of catastrophic incidents. According to the National Fire Protection Association (NFPA), properly installed flame arrestors can decrease the likelihood of explosions by up to 85% in facilities handling flammable substances.

In China, adherence to standards set by organizations such as the Standards Administration of China (SAC) is essential. The SAC mandates that flame arrestors must meet specific performance criteria outlined in GB 50016-2014, which focuses on design and manufacturing practices to ensure reliability under various operating conditions. Additionally, compliance with international standards such as those from the American Society of Mechanical Engineers (ASME) can provide an added layer of safety assurance for industries operating in high-risk environments. As we approach the 138th China Import and Export Fair in 2025, it is crucial for stakeholders to prioritize these regulatory standards to safeguard their operations and protect public safety.

This bar chart illustrates the number of incidents related to flame arrestors reported in China from 2018 to 2023. A notable increase in incidents is observed in 2022, highlighting the importance of regulatory standards and safety measures in the industry.

Flame arrestors play a crucial role in enhancing safety in various industrial settings, particularly in environments where flammable vapors are present. At the 138th China Import and Export Fair in 2025, discussions surrounding the successful implementation of tank flame arrestors have emerged. One notable case study involved a chemical manufacturing plant that faced significant fire hazards due to the nature of its operations. The installation of flame arrestors in their storage tanks significantly reduced the risk of explosions, allowing for safer handling of volatile substances.

Another compelling case came from an oil and gas facility that relied heavily on tank storage. After a thorough risk assessment, the facility decided to integrate advanced flame arrestor technology, resulting in a dramatic decrease in incident rates. These instances underscore the importance of flame arrestors in safeguarding facilities against fire hazards, demonstrating their effectiveness across different sectors.

Tips: When considering the implementation of flame arrestors, it's vital to engage with experts who can conduct comprehensive risk assessments. Regular maintenance of these safety devices is equally important to ensure their optimal functionality. Moreover, training staff on the importance and operation of flame arrestors can significantly enhance safety protocols within the facility.

As safety concerns continue to escalate in various industrial sectors, the 138th China Import and Export Fair 2025 will highlight the importance of advanced safety solutions for tank storage systems. Future trends indicate a growing emphasis on integrating flame arrestors, which play a critical role in preventing the propagation of flames in fuel or chemical storage tanks.

These devices not only safeguard against catastrophic incidents but also ensure compliance with increasingly stringent regulatory standards.

Moreover, innovations in materials and technology are paving the way for more efficient flame arrestors. The advent of smart sensors and monitoring systems can enhance the effectiveness of tank safety measures by providing real-time data on potential hazards.

These developments signify a shift towards proactive safety management in tank storage, where the focus is on prevention rather than reaction. As industries adapt to these advancements, the role of flame arrestors will continue to evolve, further strengthening safety protocols in the storage and handling of hazardous materials.