Leave Your Message

In recent years, the importance of effective safety solutions in industrial settings has been underscored by a series of alarming incidents involving hydrogen, a highly flammable gas. As industries increasingly adopt hydrogen for energy and production processes, the need for specialized equipment, such as Hydrogen Flame Arrestors, has become paramount. According to a report by the International Energy Agency, the global hydrogen economy is expected to grow significantly, with a projected market size of $200 billion by 2030. This surge emphasizes the critical requirement for robust safety measures to manage the risks associated with hydrogen usage.

In recent years, the importance of effective safety solutions in industrial settings has been underscored by a series of alarming incidents involving hydrogen, a highly flammable gas. As industries increasingly adopt hydrogen for energy and production processes, the need for specialized equipment, such as Hydrogen Flame Arrestors, has become paramount. According to a report by the International Energy Agency, the global hydrogen economy is expected to grow significantly, with a projected market size of $200 billion by 2030. This surge emphasizes the critical requirement for robust safety measures to manage the risks associated with hydrogen usage.

Industry expert Dr. Emma Chen, a leading researcher at the National Institute of Safety Technology, states, "The implementation of Hydrogen Flame Arrestors is not just a regulatory requirement but a fundamental necessity to prevent catastrophic events in hydrogen applications." Her insight highlights the dual role these devices play in enhancing safety and compliance within various sectors, including chemical manufacturing and renewable energy. In light of these industry dynamics, this article will explore the top five Hydrogen Flame Arrestors available in 2025, offering essential tips for industries in their quest to bolster safety while utilizing hydrogen as a clean energy source.

As industries increasingly adopt hydrogen as a clean energy source, the need for advanced safety solutions becomes critical. In 2025, the top hydrogen flame arrestors showcase innovative features designed to enhance operational safety. According to a report by Market Research Future, the global hydrogen market is projected to reach USD 11.38 billion by 2026, underscoring the demand for effective safety measures. Modern flame arrestors, equipped with advanced materials and design flexibility, provide robust protection against potential ignition and explosions in various industrial environments.

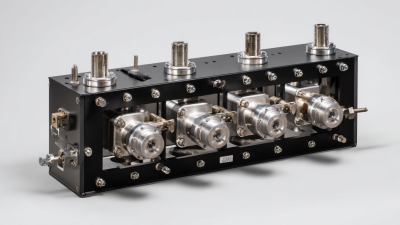

One standout innovation is the integration of smart sensors into flame arrestors. These sensors monitor temperature and gas concentrations in real-time, allowing for immediate alerts if levels reach critical thresholds. Additionally, many top models come with modular designs, which not only facilitate easier installation and maintenance but also enhance adaptability to different system configurations. As noted by the Hydrogen Safety Panel, these advancements can significantly reduce risks associated with hydrogen handling, making them essential components for industries venturing into hydrogen technologies.

| Model | Material | Pressure Rating (bar) | Temperature Rating (°C) | Innovative Feature |

|---|---|---|---|---|

| HA-100A | Stainless Steel | 10 | 250 | Self-resetting mechanism |

| HA-200B | Aluminum | 15 | 300 | Variable geometry design |

| HA-300C | Carbon Steel | 20 | 350 | Integrated flame detector |

| HA-400D | Composite | 25 | 400 | Low weight, high strength |

| HA-500E | Bronze | 30 | 450 | Hygienic design |

Hydrogen flame arrestors play a crucial role in various industries where hydrogen is used, ensuring safety and preventing catastrophic incidents. Key industries benefiting from this vital technology include the chemical manufacturing sector, where hydrogen is a primary feedstock, and the energy sector, especially in the production of green hydrogen. In these environments, flame arrestors are essential for protecting facilities and workers from potential explosions that can occur due to the flammable nature of hydrogen gas.

Hydrogen flame arrestors play a crucial role in various industries where hydrogen is used, ensuring safety and preventing catastrophic incidents. Key industries benefiting from this vital technology include the chemical manufacturing sector, where hydrogen is a primary feedstock, and the energy sector, especially in the production of green hydrogen. In these environments, flame arrestors are essential for protecting facilities and workers from potential explosions that can occur due to the flammable nature of hydrogen gas.

When selecting a hydrogen flame arrestor, it’s critical to consider factors such as the specific application, temperature ranges, and installation requirements. Manufacturers should provide comprehensive specifications to ensure compatibility with existing systems. Additionally, regular maintenance checks are vital to guarantee optimal performance and reliability.

Tip: Always consult with a safety expert to assess your facility’s unique needs before purchasing hydrogen flame arrestors. Clear communication with your supplier can also lead to customized solutions that enhance safety measures effectively. Keeping the arrestors clean and free from obstructions will greatly improve their functionality and lifespan.

Hydrogen flame arrestors are essential safety devices designed to prevent the spread of flames in environments where hydrogen is used. Compliance with safety standards and regulations is crucial in the design and implementation of these devices, ensuring they provide maximum protection in industrial settings. Organizations like the National Fire Protection Association (NFPA) and the American Society of Mechanical Engineers (ASME) have established guidelines that dictate the specifications and testing of flame arrestors, driving manufacturers to innovate while adhering to safety benchmarks.

Tip: When selecting a hydrogen flame arrestor, always verify that it meets relevant industry standards, as this can significantly influence its effectiveness and reliability.

Additionally, regulations often require regular inspections and maintenance of flame arrestors to ensure they function correctly. Adhering to these regulations not only enhances safety but also mitigates potential legal liabilities for companies. Incorporating alarms or monitoring systems can further boost safety, providing real-time alerts in case of malfunctions or increased pressure.

Tip: Consider implementing a routine maintenance schedule for flame arrestors to ensure they remain in optimal condition, helping to prevent any safety breaches in the workplace.

When evaluating hydrogen flame arrestors, a comparative analysis of performance and reliability among leading models reveals critical insights for industrial applications. Manufacturers often prioritize different design elements, such as the type of materials used and the internal geometries that influence flame propagation dynamics. Models that incorporate advanced materials, like stainless steel with enhanced corrosion resistance, tend to offer superior longevity and performance under harsh conditions, making them indispensable for industries handling hydrogen safely.

Moreover, performance metrics such as response time to ignition incidents and failure rates under duress are crucial factors when selecting a flame arrestor. Some leading models demonstrate remarkable effectiveness, exhibiting minimal delay in quenching flames, which is vital in maintaining safety in environments with high hydrogen concentrations. Additionally, reliability assessments indicate that arrestors with robust certifications and extensive field testing often provide more assurance of consistent operation. This comparative analysis not only highlights the best-in-class models but also assists industries in making informed decisions for their safety mechanisms.

As industries increasingly turn to hydrogen as a clean energy source, the demand for advanced safety solutions, particularly hydrogen flame arrestors, is paramount. The future of hydrogen flame arrestor technology will likely focus on improved materials and designs that can withstand higher pressures and temperatures. Innovations such as lightweight composite materials and advanced coatings are expected to enhance durability while reducing overall weight, making installations simpler and more efficient.

Moreover, developments in smart technology can significantly impact the design of flame arrestors. Integrating sensors that monitor gas flow and potential ignition sources will allow for real-time data analysis, enabling preventative measures before an incident occurs. This shift towards smart solutions not only enhances safety but also supports predictive maintenance, ensuring that equipment remains functional and reliable over time. As industries adopt these new technologies, we can anticipate a safer and more efficient hydrogen economy.