Leave Your Message

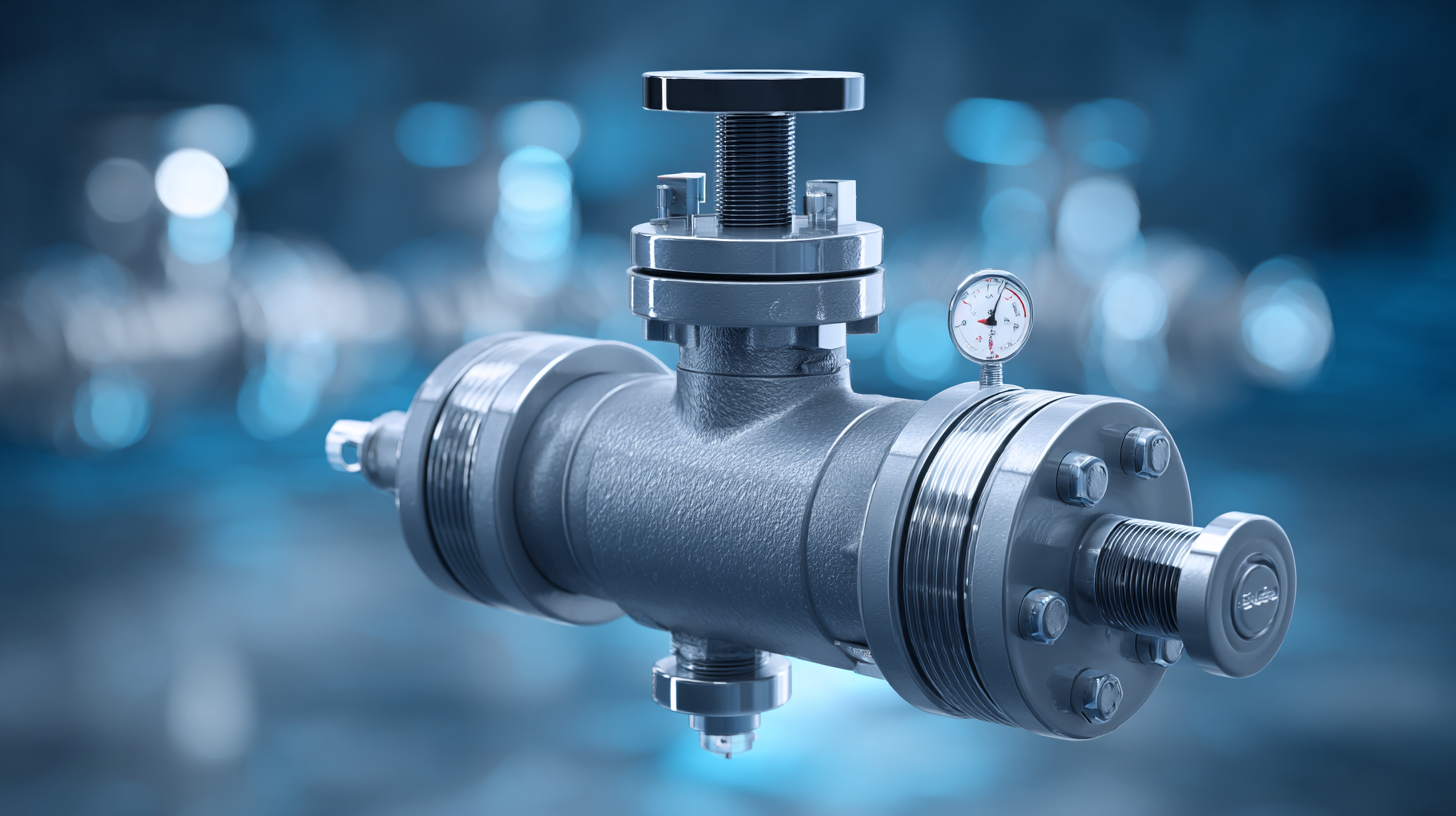

In the realm of industrial applications, Vacuum Relief Valves play a crucial role in maintaining safety and efficiency across a variety of processes. According to a report by MarketsandMarkets, the global market for vacuum relief valves is projected to reach USD 1.2 billion by 2025, driven by growing demand in the oil and gas, chemical, and pharmaceutical industries. These valves prevent the buildup of vacuum pressure, which can lead to catastrophic equipment failures and operational disruptions. An understanding of the different types of vacuum relief valves, their specific features, and appropriate applications is essential for engineers and facility managers aiming to optimize their systems. As industries continue to evolve and adopt advanced technologies, selecting the best vacuum relief valve becomes paramount in addressing both current challenges and future demands, ensuring compliance with prevailing industry standards and enhancing overall operational integrity.

Vacuum relief valves (VRVs) play a crucial role in maintaining optimal pressure levels within various industrial systems. These devices prevent the creation of vacuum conditions that can lead to equipment damage, structural deformation, or even catastrophic failures. According to a report by MarketsandMarkets, the global vacuum valve market is expected to grow from $1.3 billion in 2020 to $1.9 billion by 2025, indicating a rising awareness of the importance of such safety mechanisms across multiple sectors, including pharmaceuticals and food processing.

There are several types of vacuum relief valves, each designed for specific applications. For example, spring-loaded VRVs are commonly used in bulk storage tanks to ensure proper pressure balance during liquid transfer. On the other hand, weighted VRVs are well-suited for high-temperature applications, providing reliable protection under challenging conditions. Understanding the distinct features and applications of these valves is essential for industries seeking to optimize their operational efficiency while ensuring safety compliance, as underscored by a recent study from Global Information, Inc., which highlights that effective vacuum management can reduce equipment failures by up to 30% in manufacturing processes.

| Type | Features | Applications | How to Choose |

|---|---|---|---|

| Spring-Loaded | Simple design, responsive, adjustable setting | Chemical processing, food and beverage | Consider system pressure and liquid viscosity |

| Pneumatic | Uses air pressure, suitable for large systems | Pharmaceuticals, oil and gas | Evaluate air supply and response time |

| Electric | Automated operation, programmable settings | Water treatment, HVAC systems | Check power requirements and compatibility |

| Timer-Based | Operates on a set schedule, configurable | Waste treatment, manufacturing | Consider cycle time and process needs |

Vacuum relief valves play a crucial role in various industrial applications, and understanding their key features is essential for optimizing performance. These devices are designed to prevent vacuum conditions that can cause damage to vessels or systems. Common types include spring-loaded, weight-loaded, and pilot-operated options, each offering unique benefits tailored to specific operational needs. For instance, spring-loaded valves are often favored for their quick response times, while pilot-operated valves deliver enhanced efficiency and precise control, making them ideal for more complex systems.

Vacuum relief valves play a crucial role in various industrial applications, and understanding their key features is essential for optimizing performance. These devices are designed to prevent vacuum conditions that can cause damage to vessels or systems. Common types include spring-loaded, weight-loaded, and pilot-operated options, each offering unique benefits tailored to specific operational needs. For instance, spring-loaded valves are often favored for their quick response times, while pilot-operated valves deliver enhanced efficiency and precise control, making them ideal for more complex systems.

As industries continue to advance, the importance of performance monitoring in vacuum systems cannot be overstated. Recently, the proliferation of sensor technologies has emerged as a revolutionary approach to overseeing hydraulic systems, including vacuum valves. These sensors can identify real-time performance metrics, ensuring that vacuum relief valves function optimally. With the global vacuum valve market projected to grow significantly in the coming years, investing in the right type of valve equipped with advanced monitoring technology will be crucial for improving safety and operational efficiency across various engineering sectors.

Vacuum relief valves play a crucial role across various industries, ensuring safety and operational efficiency by preventing the formation of vacuum conditions. In the petroleum and chemical sectors, for example, these valves are vital for protecting storage tanks and pipelines from potential collapse or structural failure. According to a report by MarketsandMarkets, the global market for vacuum relief valves is projected to reach USD 1.78 billion by 2025, reflecting the essential nature of these components in maintaining system integrity.

In the pharmaceutical industry, vacuum relief valves are integral to processes that require strict control over environmental conditions to prevent contamination. With the demand for pharmaceutical products expected to grow at a CAGR of 7.4%, the importance of reliable vacuum systems equipped with high-quality relief valves cannot be overstated. Industries must choose valves based on their specific requirements; factors such as the material compatibility, pressure ratings, and installation requirements play a significant role in ensuring optimal performance. For instance, a valve made from stainless steel may be preferred in corrosive environments, while a rubber-seated valve might be more suitable for low-pressure applications.

When selecting the right vacuum relief valve, several critical factors must be considered to ensure optimal performance and safety. One primary consideration is the application’s pressure range and vacuum levels. According to a report by Research and Markets, the global vacuum equipment market is expected to grow substantially, indicating an increasing demand for reliable vacuum systems. This growth necessitates vacuum relief valves that can effectively handle varying pressure conditions without failure.

Another crucial factor is the materials of construction. Depending on the process media, corrosive resistance may be a priority. For instance, valves made from stainless steel or specialized polymers can withstand harsher environments, thus extending their operational lifespan. In a study by The American Society of Mechanical Engineers (ASME), it was found that improper material selection can lead to mechanical failure in up to 15% of vacuum systems. Therefore, evaluating chemical compatibility and environmental conditions plays a significant role in ensuring the reliability of vacuum relief valves in various applications.

When considering vacuum relief valves, understanding the quality assurance processes, especially within the context of Chinese manufacturing standards, is critical for reliability and performance. Chinese manufacturers adhere to stringent guidelines, including ISO certification and other local compliance measures designed to ensure product safety, efficiency, and durability. These standards cover not only materials and construction techniques but also performance testing, ensuring that valves can withstand the demands of various applications.

Moreover, the focus on quality assurance in Chinese manufacturing reflects an increasing global competitiveness, with many manufacturers investing in advanced technologies and skilled labor. This commitment to quality ensures that vacuum relief valves meet international standards, making them suitable for diverse industrial settings, from food processing to pharmaceuticals. By critically assessing these standards, engineers and purchasing managers can make informed decisions, ultimately choosing vacuum relief valves that deliver optimal performance while adhering to rigorous quality assurance protocols.