Leave Your Message

In the world of industrial processes and fluid management, the importance of selecting the right equipment cannot be overstated. One critical component that often gets overlooked is the Vacuum Relief Valve, a vital device designed to protect systems from vacuum conditions that can cause significant damage or failure. As the demand for reliable and efficient operations increases, understanding the advantages of high-quality vacuum relief valves becomes essential. Not only do these valves play a crucial role in maintaining optimal pressure levels, but they also offer substantial benefits in terms of after-sales service and maintenance costs. Choosing the best vacuum relief valve tailored to your specific requirements can save considerable time and resources down the line, ensuring seamless functionality and longevity of your systems.

In this ultimate guide, we will delve into the various factors to consider when selecting a vacuum relief valve, emphasizing the significant impact that after-sales support and repair expenses can have on your overall decision-making process.

When selecting a vacuum relief valve, one crucial aspect often overlooked is the importance of after-sales service. This service can make a significant difference in the long-term performance and reliability of your valve. Manufacturers and suppliers that provide comprehensive after-sales support ensure that any installation issues, maintenance needs, or unexpected operational challenges can be addressed swiftly. This support not only minimizes downtime but also extends the product's lifespan, ultimately saving you money and headaches in the process.

Effective after-sales service includes regular maintenance check-ups, troubleshooting assistance, and availability of replacement parts. A supplier that prioritizes customer satisfaction will offer guidance and resources to help you optimize the performance of your vacuum relief valve. Additionally, training sessions for your staff can enhance their understanding of the product, leading to fewer operational errors and improved safety. Investing in a vacuum relief valve from a reputable provider with strong after-sales service can significantly enhance your operational efficiency and ensure peace of mind in your processes.

When considering vacuum relief valves, one of the most crucial decisions is whether to repair or replace them. Analyzing the cost of repairs versus replacement can save you significant expenses in the long run. While repairs may seem economical initially, it is essential to evaluate the frequency of issues, as repeated repairs can accumulate costs and lead to downtime.

**Tip:** Always document repair history and maintenance records to identify patterns that may justify a replacement. If a valve has required multiple repairs in a short period, it could indicate that it is nearing the end of its service life.

Replacement, on the other hand, may come with a higher upfront cost but can provide long-term benefits such as improved efficiency and reliability. Additionally, new vacuum relief valves often incorporate advanced technology, ensuring better performance and reducing the risk of future failures.

**Tip:** Consider the warranty and durability of new models before making your purchase; investing slightly more in a high-quality valve can reduce long-term operational costs.

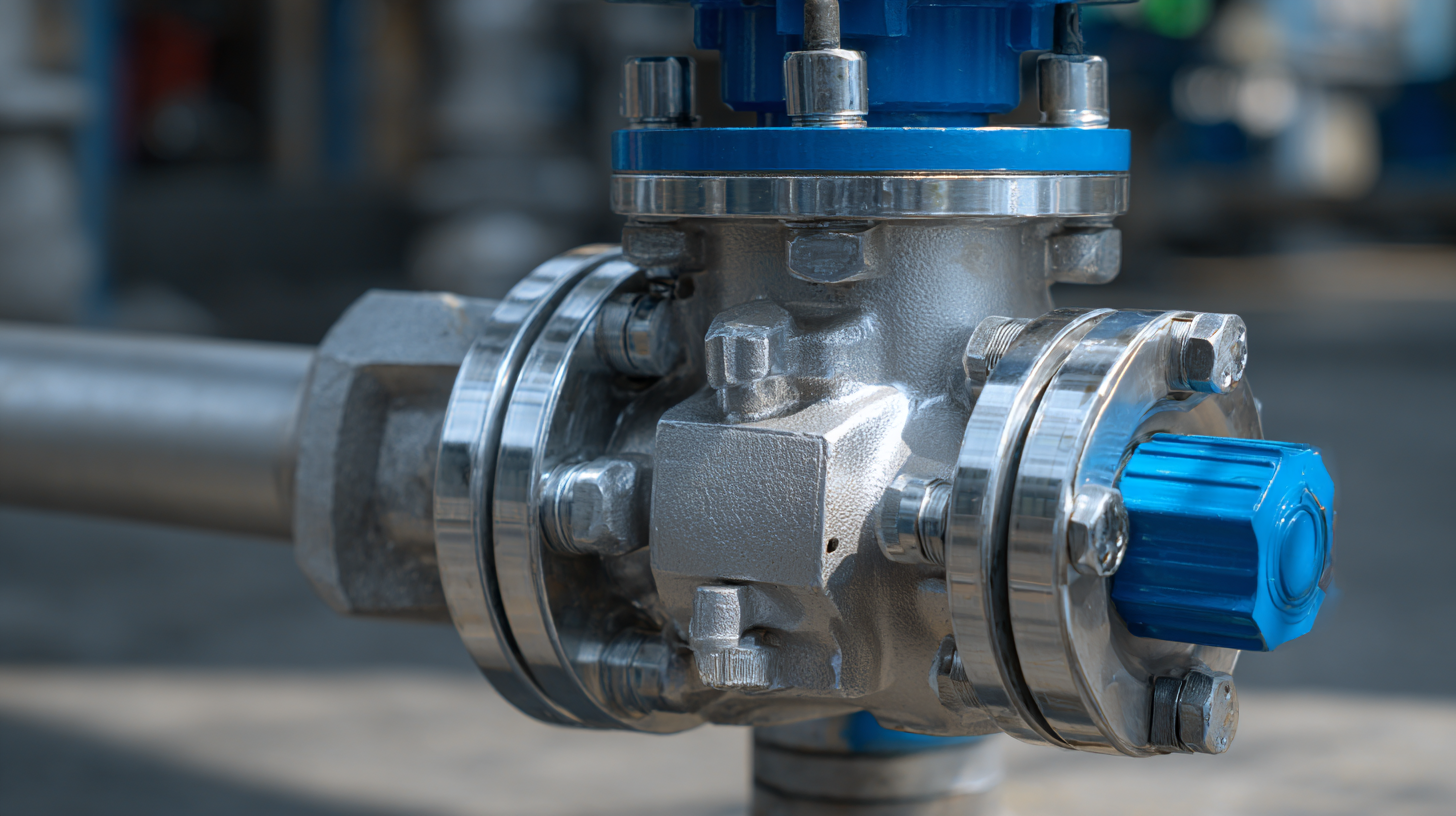

When selecting a vacuum relief valve, understanding key features can greatly enhance your maintenance routines and overall efficiency. One crucial aspect to consider is the valve's material. Opt for a valve made from corrosion-resistant materials such as stainless steel or high-quality plastics, which can withstand varying pressure and temperature conditions. This not only prolongs the valve's life but also minimizes the chances of failures that could disrupt your operations.

Another important feature is the sizing of the valve. Proper sizing ensures that the valve can manage the maximum expected vacuum levels without being overwhelmed. To avoid common pitfalls, make sure to consult with a professional to determine the ideal specifications based on your system’s requirements.

Additionally, look for valves with straightforward maintenance protocols. Easy access points for cleaning and inspection will save time and reduce operational downtimes. **Tips**: Regularly schedule maintenance checks to spot any wear and tear early on, and keep a log of performance metrics to identify potential issues before they escalate.

When selecting a vacuum relief valve, warranty and customer support play crucial roles in ensuring a reliable investment. According to a report by Markets and Markets, the global vacuum relief valve market is projected to reach $1.1 billion by 2025, highlighting the growing demand for these essential components in various industries. A robust warranty can offer peace of mind, protecting against potential defects and performance issues. Many manufacturers provide warranties ranging from one to five years, which can significantly impact the long-term cost-effectiveness of your choice.

Customer support is equally vital when navigating the complexities of vacuum relief valves. A 2022 survey by the Customer Service Institute indicated that 75% of consumers would choose one supplier over another based on the level of customer service provided. When complications arise, having access to knowledgeable technical support can facilitate quick troubleshooting and minimize downtime. Companies that invest in strong customer service can not only enhance user satisfaction but also foster brand loyalty, making them a more attractive choice for consumers looking to invest in quality vacuum relief valves.

When it comes to vacuum relief valves, understanding the common failure rates and maintenance costs can be crucial for making informed decisions. Industry statistics indicate that many vacuum relief valves experience a failure rate of up to 15-20% due to factors such as corrosion, wear and tear, and improper installation. This underscores the importance of regular inspections and timely replacements to ensure operational efficiency and safety.

To minimize maintenance costs, consider implementing a routine maintenance schedule. Regularly checking the seals and operational parts can help detect issues early, preventing costly downtime. Additionally, keeping a log of inspections may reveal patterns that inform future purchase decisions or upgrades.

Tip: Always choose a vacuum relief valve with a reliable warranty. This not only provides peace of mind but can also save costs in the long run if replacement or repairs are needed. Consider consulting with manufacturers about the most common failure points relevant to their products, ensuring you are well-informed about the options available. By staying proactive and educated, you can significantly enhance the longevity and performance of your vacuum relief valves.

| Valve Type | Common Failure Rate (%) | Average Maintenance Cost ($) | Typical Lifespan (Years) | Recommended Applications |

|---|---|---|---|---|

| Spring-loaded | 15% | 200 | 5-10 | Chemical processing |

| Pneumatic | 10% | 150 | 7-12 | Food processing |

| Electrically actuated | 8% | 250 | 10-15 | Pharmaceuticals |

| Diaphragm | 12% | 180 | 5-8 | Water treatment |

| Ball valve | 5% | 120 | 10-20 | Oil & gas |