Leave Your Message

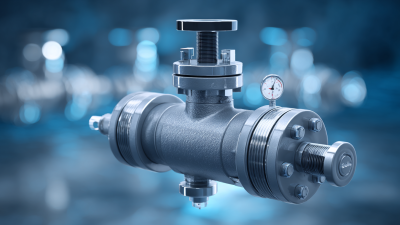

In today's fluid control systems, the importance of precision and reliability cannot be overstated. According to a report by MarketsandMarkets, the global valve market is projected to grow from USD 80.73 billion in 2020 to USD 102.99 billion by 2025, with pilot operated diaphragm valves playing a crucial role in this expansion. These valves offer unique benefits in managing the flow of fluids, particularly in applications requiring tight shut-off and minimal leakage.

The distinctive design of the Pilot Operated Diaphragm Valve not only enhances the operational efficiency of fluid systems but also reduces maintenance costs over time. As industries increasingly prioritize efficiency and sustainability, understanding the mechanics and advantages of these valves becomes imperative for optimizing fluid control systems and adapting to evolving demand in a competitive marketplace.

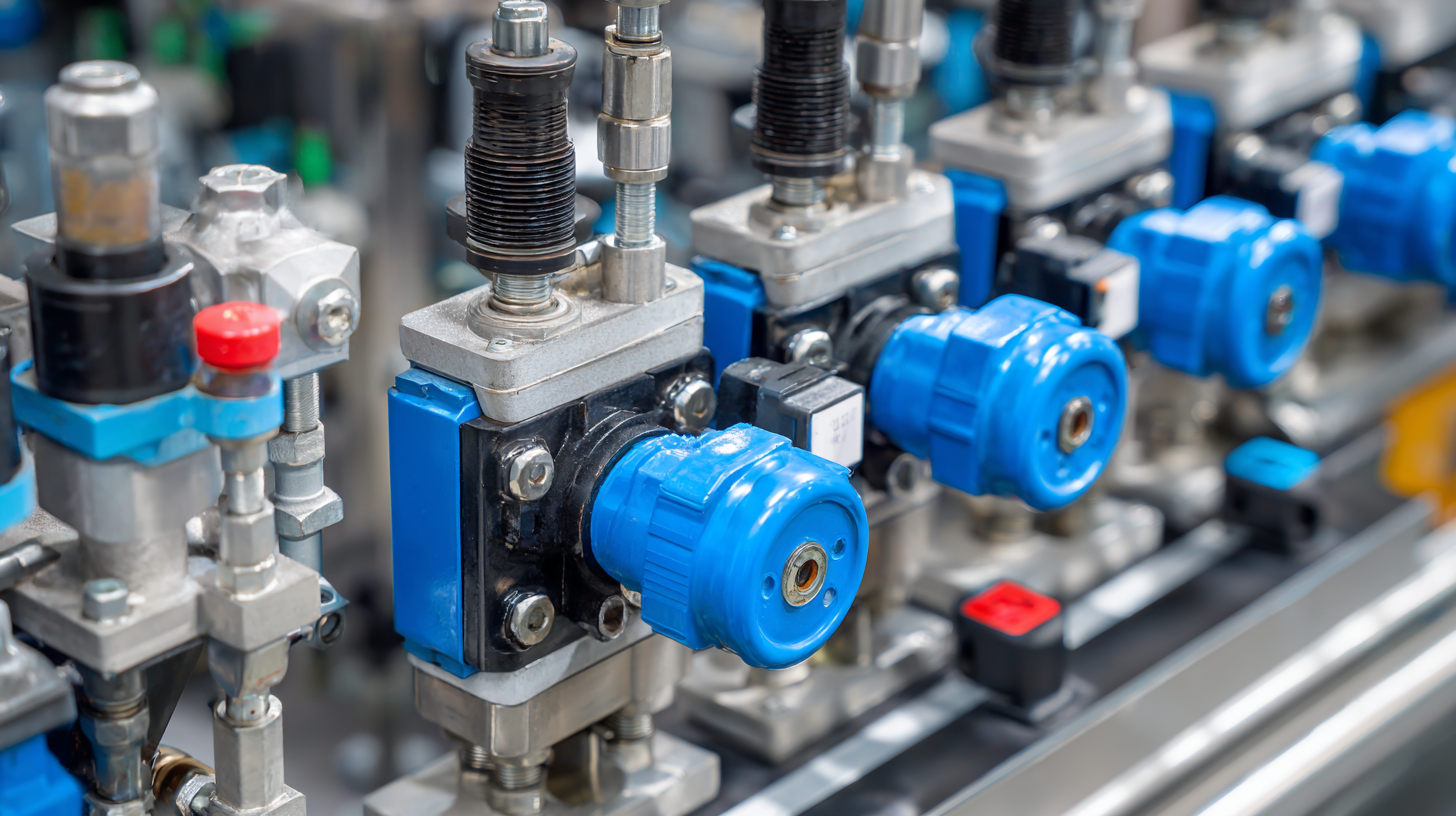

Pilot operated diaphragm valves are essential components in fluid control systems, often utilized in industries such as chemical processing, water treatment, and food production. These valves function based on the differential pressure created by a pilot signal, allowing them to operate efficiently with low energy consumption. According to a report from the International Society of Automation, incorporating pilot operated diaphragm valves can improve system reliability by up to 25%, significantly reducing downtime in critical applications.

To ensure optimal performance of pilot operated diaphragm valves, it is crucial to understand their design and operational principles. The diaphragm separates the fluid media from the actuator, providing a leak-proof and safe operation. Furthermore, the ability to modulate flow precisely makes these valves suitable for applications requiring fine control. Operators should regularly check the pilot pressure and ensure the diaphragm is not damaged, as this can lead to inefficient operation and potential system failures.

**Tips:** Always monitor the maintenance schedule for diaphragm valves and regularly inspect pilot systems for any signs of wear. Keeping a clean working environment around the valves can prevent external contaminants from affecting their performance. Additionally, educating staff about the working principles of these valves can enhance their hands-on troubleshooting skills, ensuring a more resilient fluid control system.

| Dimension | Description | Importance |

|---|---|---|

| Pressure Range | Operating pressure from 0 to 150 psi | Ensures valve performance under different system pressures |

| Flow Rate | Capable of handling flow rates up to 200 GPM | Critical for determining the efficiency of fluid transport |

| Material | Made from corrosion-resistant materials (e.g., PVC, stainless steel) | Enhances durability and lifespan in various environments |

| Actuation Type | Pilot-operated with automatic control features | Increases control accuracy and reduces manual intervention |

| Temperature Range | Operates effectively in temperatures from -20°C to 80°C | Ensures performance in various operational conditions |

| Size Options | Available in sizes ranging from 1 inch to 4 inches | Provides flexibility to fit different piping systems |

Pilot operated diaphragm valves are essential components in fluid control systems, offering several key features that enhance performance and reliability. One of the most significant advantages is their ability to provide precise flow regulation. These valves utilize a pilot pressure that can control the diaphragm's position, allowing for accurate adjustments to fluid flow rates. This precision is critical in applications requiring sensitive control, such as in pharmaceuticals or chemical processing.

Another noteworthy feature is the ability to handle a wide range of fluids and pressures. Pilot operated diaphragm valves are designed to manage aggressive chemicals and high-pressure conditions, making them suitable for various industrial applications. Their resilient diaphragm construction ensures longevity and resistance to wear and tear, which reduces maintenance costs over time. Additionally, these valves typically provide a bubble-tight seal when closed, preventing leaks and ensuring system integrity. This combination of durability and reliability makes pilot operated diaphragm valves a smart choice for enhancing the efficiency of fluid control systems.

Pilot operated diaphragm valves offer significant advantages for industrial applications, particularly in fluid control systems that require precision and reliability. These valves feature a diaphragm that allows for a tight seal, reducing the risk of leakage and enhancing the overall efficiency of fluid handling processes. According to recent studies, pilot operated diaphragm valves can improve flow control by up to 30% compared to traditional valve systems, making them ideal for sectors such as food processing and pharmaceuticals, where hygienic standards are crucial.

In addition, innovations in control systems have led to cost savings through standardization. For instance, advanced control heads designed for diaphragm valves are now tailored for hygienic applications, minimizing customization costs while ensuring compliance with industry standards. Reports suggest that this standardization can reduce operational costs by as much as 20%, contributing to a more sustainable approach in industries that are energy-intensive. As companies strive to enhance their fluid control systems, pilot operated diaphragm valves and their associated technologies play an integral role in achieving both economic and operational efficiencies.

Pilot operated diaphragm valves are essential components in various fluid control systems, known for their reliability and efficiency in managing fluid flow. One common application is in water treatment plants, where these valves are utilized to regulate the flow of chemicals and ensure optimal water quality. According to a recent industry report by MarketsandMarkets, the global market for diaphragm valves is projected to reach $4.5 billion by 2025, with a significant segment attributed to their use in municipal water and wastewater treatment.

In addition to water treatment, pilot operated diaphragm valves are frequently employed in the pharmaceutical and food processing industries. These industries require strict adherence to hygiene standards, and the ability of these valves to provide leak-free performance makes them an ideal choice. A study published in the Journal of Fluid Engineering highlighted that diaphragm valves can enhance the precision of dosing in pharmaceutical applications, resulting in a 15% increase in overall system efficiency.

Tips: When selecting pilot operated diaphragm valves, consider materials that comply with industry regulations to ensure durability and safety. Additionally, regularly service and inspect these valves to maintain optimal performance and prevent costly downtime.

Pilot operated diaphragm valves are critical components in fluid control systems. To ensure these valves operate efficiently and maintain peak performance, regular maintenance is essential. According to a report by the Fluid Control Institute, up to 30% of valve failures can be attributed to poor maintenance practices. Implementing best practices not only extends the lifespan of these valves but also enhances overall system reliability.

Pilot operated diaphragm valves are critical components in fluid control systems. To ensure these valves operate efficiently and maintain peak performance, regular maintenance is essential. According to a report by the Fluid Control Institute, up to 30% of valve failures can be attributed to poor maintenance practices. Implementing best practices not only extends the lifespan of these valves but also enhances overall system reliability.

One important practice is to regularly inspect the diaphragm for signs of wear or damage. A strategically scheduled inspection routine can help in identifying potential issues before they escalate. Additionally, ensuring that the pilot valve is properly calibrated is crucial. This will help maintain the correct pressure differential, which directly affects the valve’s performance.

Tips:

Always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures. Consider employing predictive maintenance techniques using sensors that can monitor valve performance in real-time. This proactive approach can significantly reduce downtime and maintenance costs, ultimately leading to more efficient fluid control systems.