Leave Your Message

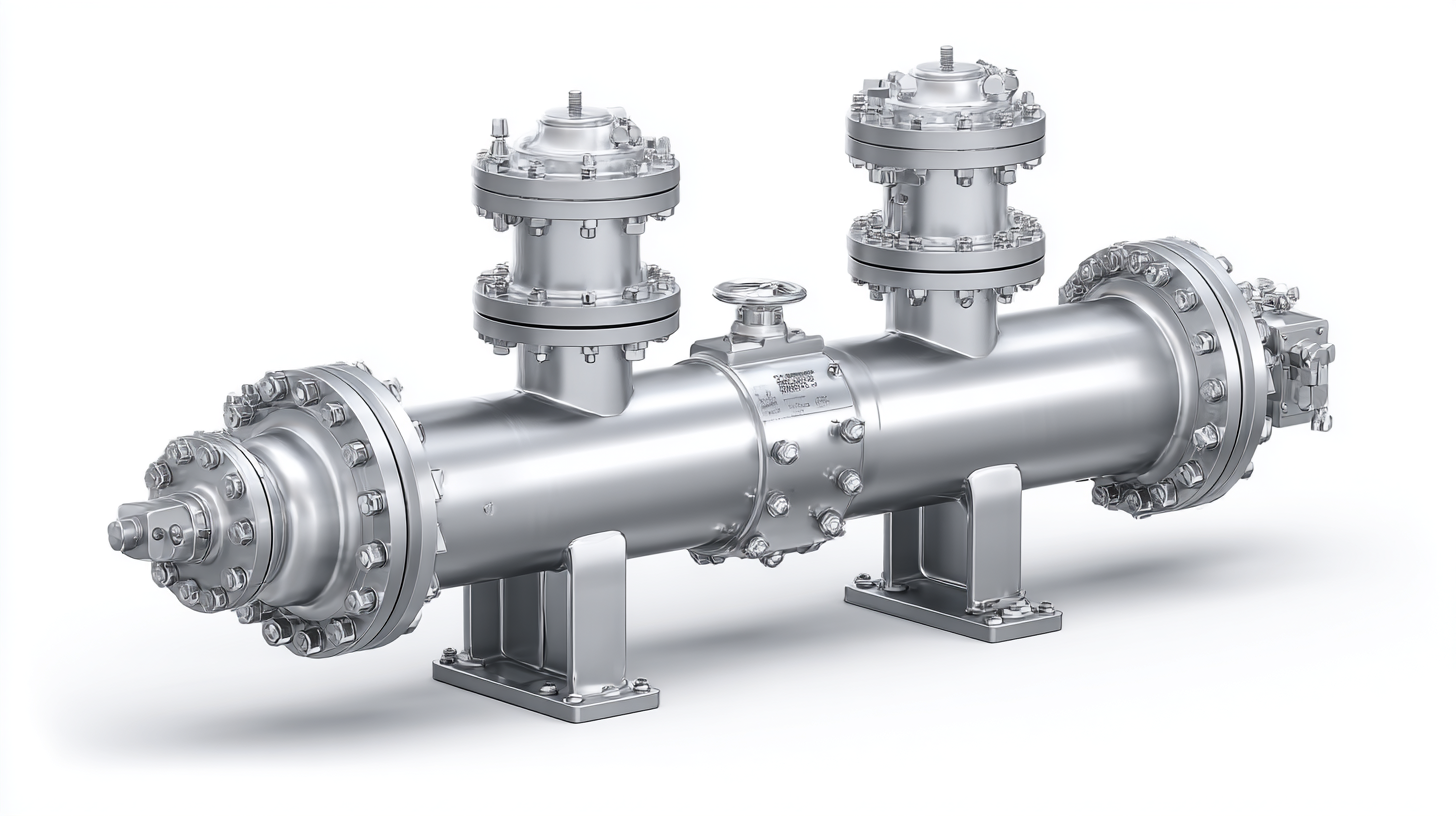

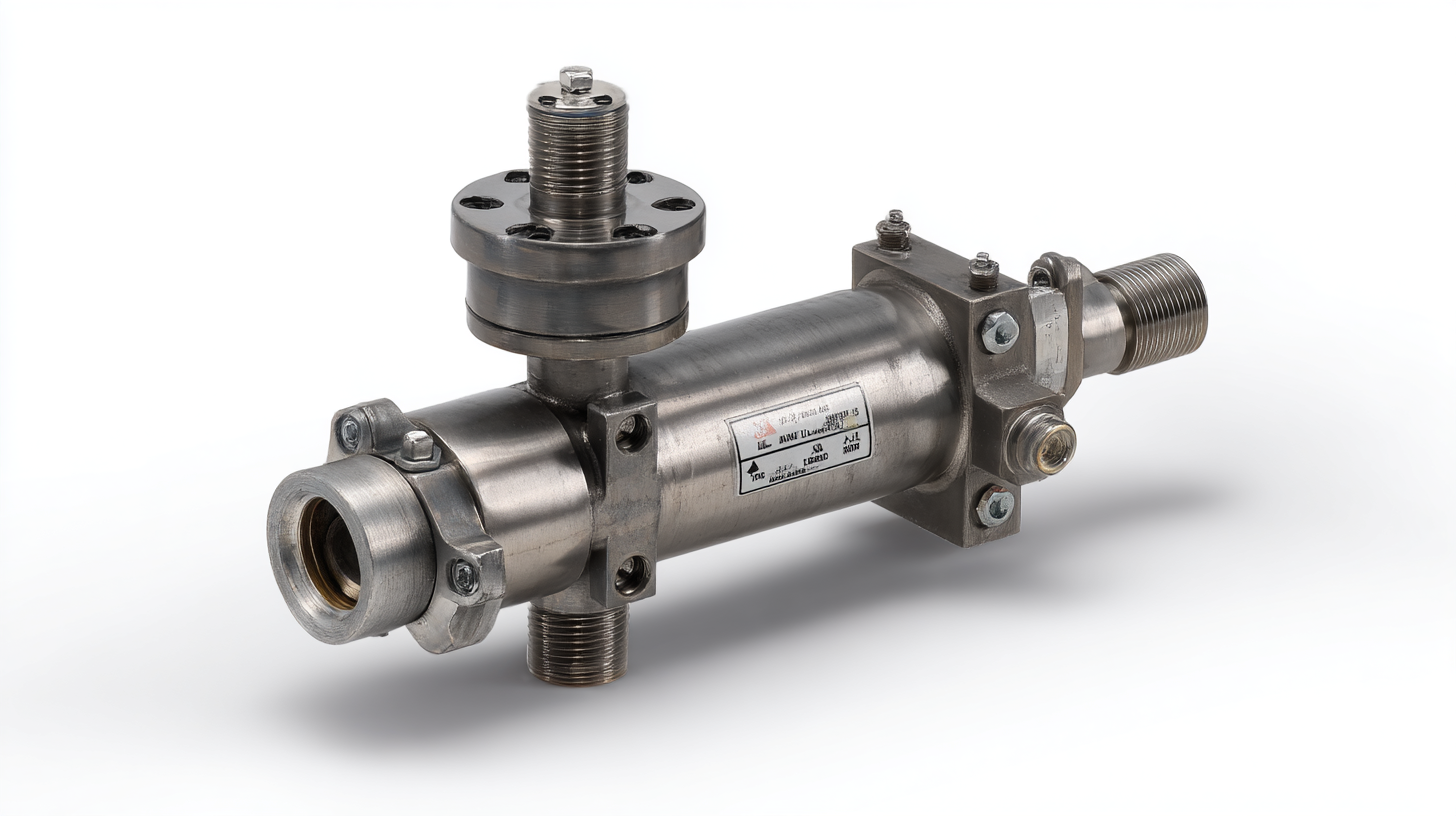

In the dynamic landscape of chemical processing, ensuring system reliability and safety is paramount. One critical component that can significantly enhance operational efficiency while preventing potential hazards is the

Pressure Vacuum Relief Valve. These valves serve as essential safety devices, protecting storage tanks and processing equipment from overpressure and vacuum conditions that could lead to catastrophic failures.

However, many facilities experience system inefficiencies and malfunctions due to improper valve selection or maintenance. In this blog, we will explore the common pitfalls associated with pressure vacuum relief valves, identify solutions to address these issues, and discuss how investing in the right valve can optimize performance and enhance safety.

By unlocking the potential of these vital components, chemical processors can safeguard their systems and streamline operations, ultimately leading to a more productive and secure working environment.

Pressure vacuum relief valves (PVRVs) play a crucial role in maintaining the safety and efficiency of chemical processing systems. As pressure builds up or drops in storage tanks or pipelines, these valves act as the first line of defense against potential system failures. By allowing excess pressure to escape and preventing vacuum conditions that can lead to tank implosion, PVRVs help protect both equipment and personnel from hazardous incidents.

In the chemical industry, where precision and safety are paramount, the importance of reliable PVRVs cannot be overstated. They not only ensure that processes run smoothly but also help in adhering to regulatory compliance standards. Regular maintenance and inspection of these valves are essential to prevent failures that could lead to costly downtime and dangerous situations. Investing in high-quality PVRVs is a proactive measure to enhance operational efficiency and safeguard the integrity of chemical processing systems. As such, understanding their function and significance is vital for anyone involved in the industry.

In chemical processing, various system failures can significantly impact efficiency, leading to increased downtime and operational costs. Common issues include pressure fluctuations, equipment leaks, and valve malfunctions. These failures not only compromise the safety of operations but also hinder productivity. For instance, inadequate pressure management can cause spills and equipment strain, necessitating expensive repairs and regulatory fines.

To combat these challenges, implementing reliable pressure vacuum relief valves is essential. These devices help maintain optimal pressure levels, preventing overpressure situations and system backups that can disrupt production. Regular maintenance of these valves is crucial; ensure they are tested and serviced according to manufacturer guidelines to prevent malfunction.

Tip: Always monitor the system's pressure and conduct routine checks on your relief valves. This proactive approach can significantly reduce the risk of unexpected failures. Additionally, investing in quality equipment can pay off in the long run by enhancing system resilience and efficiency. Prioritizing preventive measures will lead to smoother operations and a more robust processing environment.

When it comes to maximizing efficiency in chemical processing, the significance of selecting the right pressure vacuum relief valve (PVRV) cannot be overstated. According to a report by the International Journal of Chemical Engineering, the improper functioning of PVRVs can lead to equipment damage and potential safety hazards, highlighting the critical need for the right selection. One of the top tips for selecting the best PVRV is to ensure it meets the specific pressure and vacuum conditions of your system. This includes understanding the operating pressure, the maximum anticipated vacuum, and the potential for thermal expansion or contraction of the process fluids.

Another crucial consideration is the valve's material compatibility. A study by the Chemical Engineering Society indicates that over 30% of mechanical failures in PVRVs can be attributed to material degradation. Therefore, choosing materials that resist corrosion and wear, especially in harsh chemical environments, is essential. Additionally, reviewing the valve’s design specifications for features such as quick response times and minimal leakage is vital for operational efficiency. This strategic approach to valve selection ensures that chemical processing systems not only operate safely but also maintain their productivity levels.

| Feature | Description | Importance |

|---|---|---|

| Flow Capacity | The maximum flow rate the valve can handle without malfunction. | Prevents system failures due to pressure build-up. |

| Set Pressure | The pressure level at which the valve opens to relieve pressure. | Ensures safety and prevents damage by regulating internal pressures. |

| Material Compatibility | Materials used must withstand the chemical environment. | Reduces risk of corrosion and valve failure. |

| Maintenance Requirements | Frequency and ease of maintenance required for optimal performance. | Minimizes downtime and unexpected costs. |

| Response Time | Time taken for the valve to react to pressure changes. | Critical for preventing overpressure scenarios. |

| Certification Standards | Industry certifications that guarantee quality and safety. | Ensures compliance and operational safety. |

Maintaining optimal performance in chemical processing systems is vital to prevent common system failures, particularly when it comes to pressure vacuum relief valves. These valves play a crucial role in protecting equipment from pressure build-up and vacuum conditions, which can lead to catastrophic failures if not properly managed. Implementing best practices for maintenance can significantly enhance the reliability of these vital components.

One of the most important maintenance tips is to conduct regular inspections and testing of pressure vacuum relief valves. This should include checking for visible signs of wear or damage and verifying that the valve opens and closes at the specified set pressure. Additionally, establishing a routine schedule for these inspections can help identify potential issues before they escalate, ensuring smooth operations.

Another effective strategy is to keep detailed records of all maintenance activities. Documenting any repairs, replacements, or adjustments made to the valves helps track their performance over time and can provide valuable insights into patterns or recurring problems. This proactive approach not only supports efficient maintenance but also aids in complying with industry regulations and standards, further safeguarding the integrity of the entire chemical processing system.

This bar chart represents the common system failures in chemical processing and the corresponding preventive maintenance practices associated with pressure vacuum relief valves. By addressing these issues, facilities can enhance efficiency and reduce downtimes.

In the world of chemical processing, the performance of pressure vacuum relief valves (PVRVs) plays a crucial role in maintaining system integrity and safety. Innovative solutions are being introduced to enhance the functionality of these valves, addressing common failures that can lead to costly downtime and potential hazards. By focusing on advanced designs and materials, manufacturers are improving the reliability of PVRVs, ensuring they operate effectively under varying pressures.

Tip: Regular maintenance checks are essential to prevent valve malfunction. Schedule routine inspections and replace any worn components to ensure your PVRVs are always in peak condition.

Incorporating technology such as predictive analytics can further enhance PVRV performance. These systems monitor operational data in real-time, allowing for timely interventions before issues escalate. This proactive approach not only extends the lifespan of the valves but also minimizes unplanned shutdowns.

Tip: Keep detailed records of valve performance and maintenance activities. Analyzing this data can reveal patterns and help identify when upgrades or replacements are necessary, allowing for a more efficient operation overall.