Leave Your Message

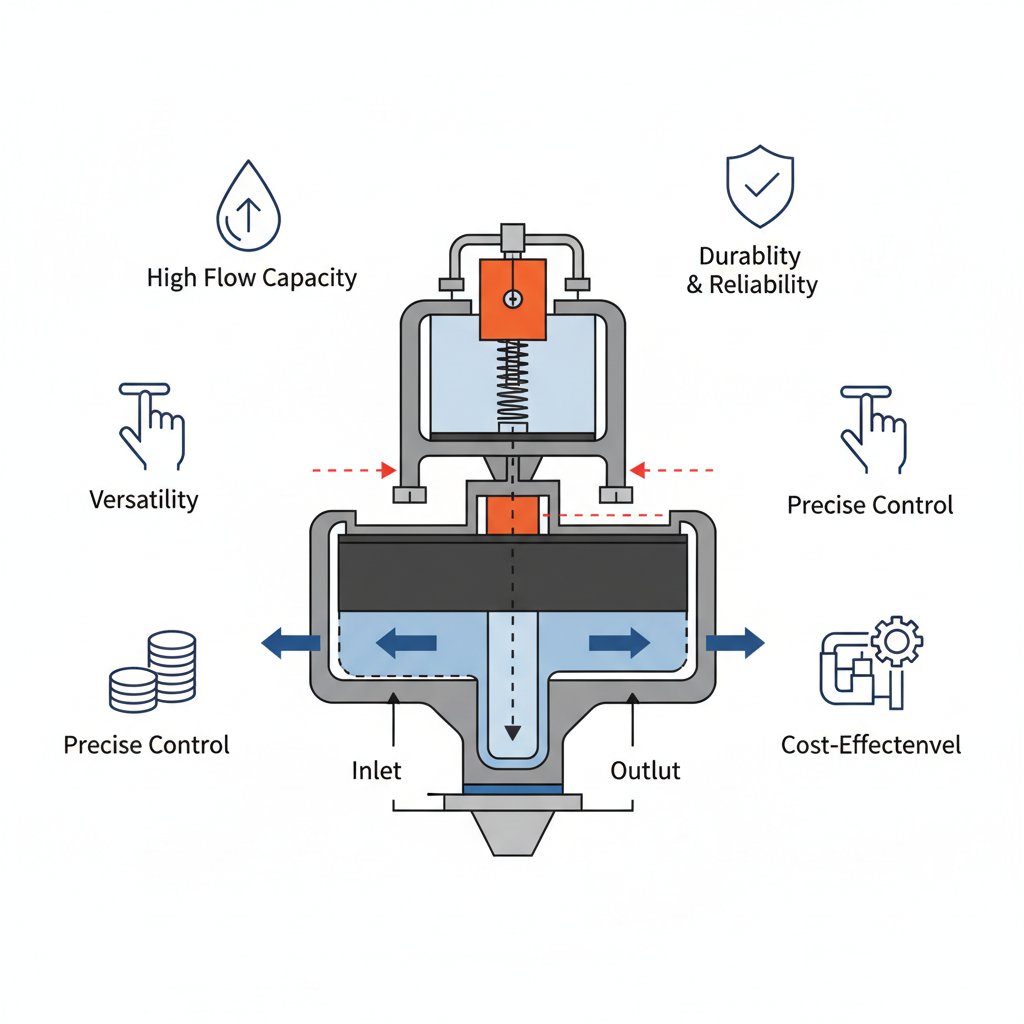

In the dynamic landscape of fluid control applications, efficiency and reliability are paramount. Among the various types of valves available, the Pilot Operated Diaphragm Valve stands out due to its unique operational advantages and suitability for a wide range of industries. According to recent industry reports, including insights from the Global Valve Market Analysis, the demand for diaphragm valves is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2027. This growth is fueled by the increasing need for precise flow control and enhanced safety measures in sectors such as water treatment, chemical manufacturing, and food processing.

Pilot Operated Diaphragm Valves are particularly favored for their ability to provide high flow capacity while maintaining low differential pressure. This makes them an effective solution for applications that require both control and efficiency. Furthermore, the recent advancements in valve technology and materials have further improved the performance and lifecycle of these valves, helping industries reduce operational costs significantly. As industries continue to seek innovative solutions for managing fluid systems, understanding the top advantages of Pilot Operated Diaphragm Valves will be crucial for making informed decisions that enhance operational efficiency and safety.

Pilot operated diaphragm valves are increasingly recognized for their precise control in fluid regulation, making them essential in various industrial applications. According to a report by Global Market Insights, the demand for diaphragm valves is projected to grow at a CAGR of over 5% from 2021 to 2027, driven by advancements in control technologies and the need for improved fluid handling capabilities. The design of pilot operated diaphragm valves allows them to respond swiftly to changes in pressure and flow conditions, providing operators with enhanced control accuracy compared to traditional valve types.

The precision of these valves can be attributed to their unique operating mechanism. By using a pilot signal to control the larger diaphragm valve, they achieve a high level of sensitivity to minute changes in system dynamics. Research conducted by the Valve Manufacturers Association indicates that pilot operated diaphragm valves can maintain a flow rate accuracy of ±1% under varying conditions, which is crucial for applications requiring stringent flow control, such as in chemical processing or water treatment facilities. This accuracy minimizes wastage and optimizes process efficiency, highlighting why these valves are becoming a preferred choice in fluid regulation across various industries.

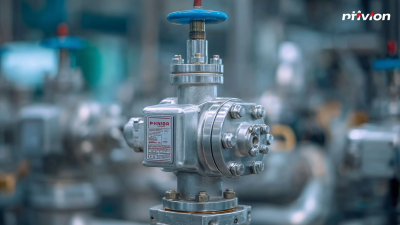

Pilot operated diaphragm valves are particularly renowned for their enhanced sealing performance in high-pressure environments, making them an ideal choice for various fluid control applications. The diaphragm design allows for superior sealing capability, effectively minimizing leakage and ensuring the integrity of fluid systems. By utilizing an internal pilot control mechanism, these valves can maintain consistent performance under varying pressure conditions, which is crucial in applications where fluid loss can lead to significant operational costs and safety concerns.

Moreover, the robustness of pilot operated diaphragm valves contributes to their reliability in high-pressure settings. The materials used in their construction are designed to withstand extreme conditions, which not only enhances the valve's lifespan but also reduces the frequency of maintenance interventions. This durability, combined with the ability to handle aggressive and corrosive fluids, positions these valves as a preferred solution in industries such as oil and gas, pharmaceuticals, and water treatment. The improved sealing performance not only promotes efficiency but also fosters a safer working environment by mitigating the risks associated with fluid leakage.

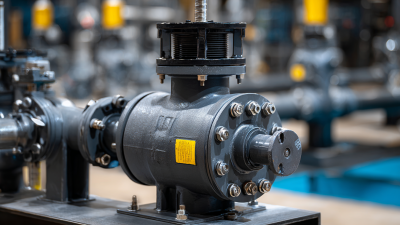

Pilot Operated Diaphragm Valves (PODVs) are increasingly favored in fluid control applications primarily due to their minimal pressure drop, which significantly enhances flow efficiency. According to a report by the Flow Control Institute, reducing pressure drop is critical for maintaining optimal flow rates and minimizing energy consumption in various industrial processes. PODVs achieve this through their unique design, which allows for greater flexibility and control under varying pressure conditions, making them ideal for both high and low flow scenarios.

One of the standout features of PODVs is that they can maintain a high flow coefficient while keeping pressure drop at a minimal level. Data indicates that in comparison to traditional valve types, PODVs can offer up to a 30% reduction in pressure drop, contributing to both cost savings and operational efficiency. Industries that rely on precise fluid control, such as chemical processing and water treatment, can benefit tremendously from these valves, ensuring that operations run smoothly without excessive energy expenditure.

Tips: When selecting valves for your application, always consider the pressure drop specifications relative to your system requirements. Also, regular maintenance can help ensure that PODVs function at their peak efficiency, prolonging service life and performance. Lastly, consulting experts on the compatibility of valve materials with your specific fluids will enhance operational reliability and safety.

Pilot operated diaphragm valves are gaining popularity in fluid control applications due to their versatility in managing various fluid types and conditions. These valves are designed to effectively handle a wide range of media, including corrosive fluids, slurries, and viscous liquids, making them an excellent choice for industries like chemical processing, water treatment, and food and beverage. The diaphragm's flexible membrane separates the fluid from the actuator, allowing for precise control while minimizing the risk of leaks and contamination.

Tip: When selecting a pilot operated diaphragm valve, consider the specific fluid characteristics such as pH, temperature, and viscosity. This ensures that the valve material and design will withstand the operational environment.

In addition to their adaptability, pilot operated diaphragm valves excel in turbulent conditions and can function effectively under varying pressures. This capability makes them suitable for applications requiring consistent performance despite fluctuating flow rates or pressure levels. Their reliable operation minimizes downtime and maintenance costs, providing an ideal solution for critical processes.

Tip: Regular maintenance is essential to prolong the lifespan of diaphragm valves. Schedule routine inspections to check for wear and ensure that the actuator is functioning correctly to prevent unexpected failures.

Pilot operated diaphragm valves offer significant advantages in fluid control, particularly in maintenance and lifespan. One of the primary benefits is their simplified maintenance. Unlike traditional valves that often require complex disassembly, diaphragm valves can be maintained with minimal effort. This accessibility reduces downtime, allowing operations to continue smoothly without prolonged interruptions for repairs.

Additionally, these valves are designed with enduring materials that can withstand harsh conditions, thereby extending their lifespan. The diaphragm acts as a protective barrier, reducing wear and erosion common in conventional valve designs. This durability not only translates to lower replacement costs but also enhances reliability in critical applications.

**Tips:** Regular inspections can help identify minor issues before they escalate, ensuring the longevity of your diaphragm valves. Moreover, investing in quality maintenance tools can simplify the upkeep process, making it less labor-intensive. Always refer to the manufacturer's guidelines for maintenance schedules tailored to specific operating conditions, as this can significantly impact valve performance and lifespan.

| Advantage | Description | Impact on Fluid Control |

|---|---|---|

| Simplified Maintenance | Easier access to components reduces downtime and labor costs. | Enhances operational efficiency. |

| Extended Life Span | Durable materials and design lead to decreased wear and tear. | Reduces replacement frequency and associated costs. |

| High Flow Capacity | Optimized design allows for greater flow rates. | Improves overall system performance. |

| Pressure Control | Can maintain stable pressure in various conditions. | Ensures smoother operation and reduces surges. |

| Versatile Applications | Suitable for a wide range of fluids and processes. | Flexible use across industries enhances usability. |