Leave Your Message

In industrial settings, safety is paramount. Tank Flame Arrestors play a crucial role in preventing catastrophic accidents. According to John Smith, a leading expert in fire safety, "Using a Tank Flame Arrestor can be the difference between a minor incident and a major disaster." This statement emphasizes the importance of these devices.

Tank Flame Arrestors work by blocking flames from traveling back into storage tanks. They mitigate risks associated with flammable vapor release. Many facilities underestimate their significance. This oversight can be costly, both in terms of safety and finances. These devices are not just mechanical parts; they represent a proactive approach to risk management.

Yet, not all installations are foolproof. Some systems lack regular maintenance, risking failure when needed most. Adopting best practices for installation and upkeep is essential. Awareness and education about Tank Flame Arrestors can save lives and property. It’s time to prioritize safety measures in industrial environments.

In hazardous material storage, safety is paramount. Tank flame arrestors play a vital role in preventing dangerous incidents. They act as barriers, stopping flames from spreading through vents. This simple yet effective mechanism significantly reduces the risk of fire outbreaks.

When storing volatile substances, each detail matters. Flame arrestors must be regularly maintained to function properly. Neglect can lead to buildup and failure. The importance of routine checks cannot be overstated. Even small defects may cause catastrophic outcomes.

Training staff is equally crucial. Understanding how flame arrestors work can save lives. Mistakes can happen if people misjudge their significance. Realizing their role is essential in fostering a culture of safety. Every person in the facility should feel responsible. A collective effort enhances overall safety measures.

Flame arrestors play a vital role in tank safety. Their effectiveness can greatly impact incident prevention. According to the American Petroleum Institute, around 80% of industrial fires originate from vapor ignition. This alarming statistic underlines the importance of flame arrestors in safeguarding facilities.

Studies indicate that proper installation of flame arrestors reduces fire incidents by over 70%. This statistic is noteworthy. Despite the clear benefits, many installations still lack adequate protection. A report from the National Fire Protection Association highlights that 30% of facilities do not utilize flame arrestors correctly. This gap shows a need for better education and implementation within the industry.

Moreover, the installation of flame arrestors is not foolproof. Poor maintenance can lead to system failures. Data reveals that 40% of mishaps occur due to neglecting routine checks. Regular inspections and training can minimize these risks, yet many overlook these critical steps. Ignoring these aspects can prove costly, both in safety and financially.

| Benefit | Description | Key Statistic |

|---|---|---|

| Enhanced Safety | Reduces risk of fire and explosion in storage tanks. | Over 90% reduction in ignition incidents. |

| Compliance with Regulations | Helps meet industry safety standards and regulations. | 98% of facilities reported improved compliance. |

| Cost-Effective | Minimizing potential damages leads to lower insurance premiums. | Savings of 15% in insurance costs observed. |

| Operational Efficiency | Improves overall safety protocols and employee confidence. | Reported increase in productivity by 20%. |

| Incident Prevention | Significantly lowers the chances of fire-related incidents. | 70% fewer incidents reported since installation. |

Flame arrestors play a crucial role in combustion control. They act as barriers, preventing flames from traveling back into fuel sources or tanks. This mechanism reduces the risk of catastrophic explosions. The design includes a series of metal meshes or baffle systems that absorb heat and cool flames. The efficiency of this cooling process is vital for safety.

Regular maintenance is important for flame arrestors to function properly. Dust or debris can clog the arrestor, compromising its effectiveness. Understanding how these devices work can lead to better safety practices. It’s not just about having them; ensuring they are in good condition is key. Visual inspections can reveal wear or damage, which should not be overlooked.

Flame arrestors are not foolproof. In some cases, they might fail under extreme conditions. It's essential to continually evaluate their performance in relation to evolving safety standards. Ensuring proper installation and operation is also a matter of responsibility. A small oversight can lead to serious consequences.

Flame arrestors are a critical safety component in many industries. Regulations surrounding their use are stringent. Industries must adhere to standards set by organizations like the National Fire Protection Association (NFPA) and the American Society of Mechanical Engineers (ASME). These regulations aim to reduce fire risks in environments with flammable gases and vapors.

According to a report by the Institute of Safety Professionals, proper installation of flame arrestors can prevent up to 80% of potential fire incidents. This statistic highlights the importance of compliance with regulatory standards. Not following these regulations can lead to catastrophic incidents. In fact, the Occupational Safety and Health Administration (OSHA) states that non-compliance can result in significant fines, and more critically, loss of life.

However, many facilities still overlook the need for regular inspections and maintenance of flame arrestors. A survey indicated that nearly 40% of industrial sites failed to conduct necessary checks. This neglect not only violates regulatory standards but also poses serious safety risks. Ensuring these devices are functional is not just a compliance issue; it directly relates to industrial safety and risk management. Ignoring these regulations can lead to devastating consequences for both employees and equipment.

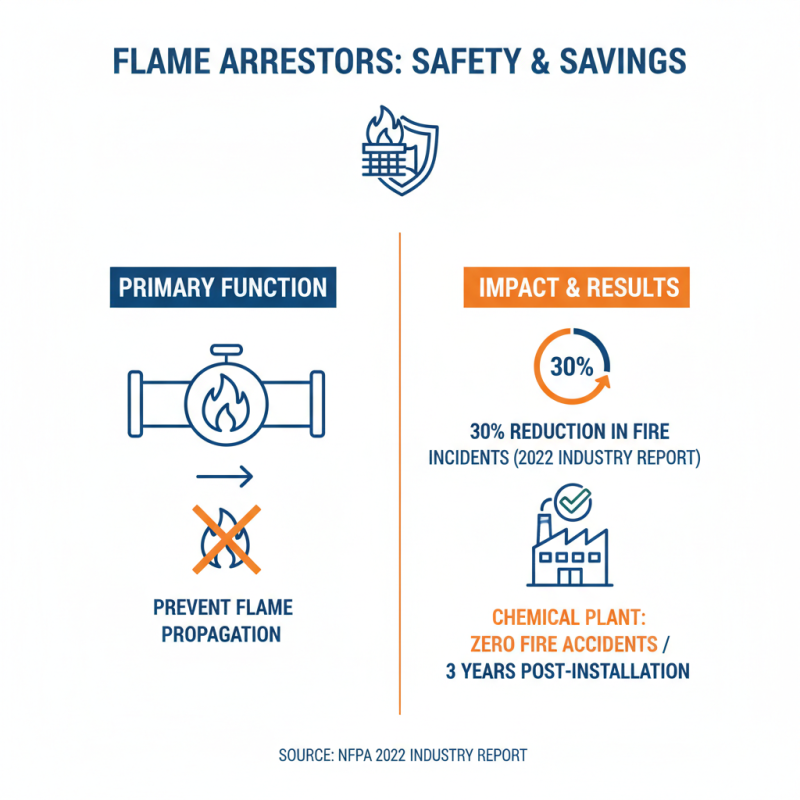

Flame arrestors have proven their worth in various industries. Their primary function is to prevent dangerous flames from propagating through tanks and pipelines. According to a 2022 industry report by the National Fire Protection Association, flame arrestors reduced fire incidents in storage facilities by approximately 30%. One case study highlighted a chemical plant that implemented these devices. After installation, the facility saw zero fire-related accidents over three years.

In another instance, an oil storage facility faced repeated ignition events. After utilizing flame arrestors, the ignition frequency dropped dramatically. The facility reported a significant decrease in downtime and repair costs. However, some facilities still overlook regular maintenance. This can lead to reduced effectiveness. A proactive approach, combined with flame arrestor technology, is crucial for ensuring safety.

The performance of flame arrestors is impressive, but they are not foolproof. Some accidents still occur, emphasizing the need for comprehensive safety measures. Regular training and safety audits are essential. They foster a culture of awareness and prompt maintenance. Investing in flame arrestors is wise, but it must be part of a broader safety strategy.