Leave Your Message

Choosing the right Pilot Operated Diaphragm Valve can be challenging. Industry expert John Smith once stated, “Selecting the right valve impacts efficiency.” His words resonate deeply in today’s engineering landscape.

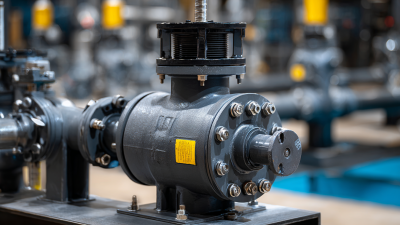

Pilot Operated Diaphragm Valves are crucial for various applications. These valves control the flow of liquids and gases with precision. They rely on pressure differential to operate. Understandably, the choice can directly influence system performance.

Many factors contribute to an informed decision. The size, material, and pressure ratings of the valve matter. Compatibility with the media being controlled is vital too. An oversight here can lead to inefficiencies. Reflecting on these details is essential for achieving optimal results.

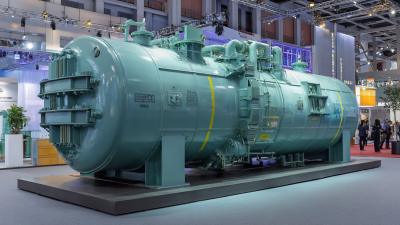

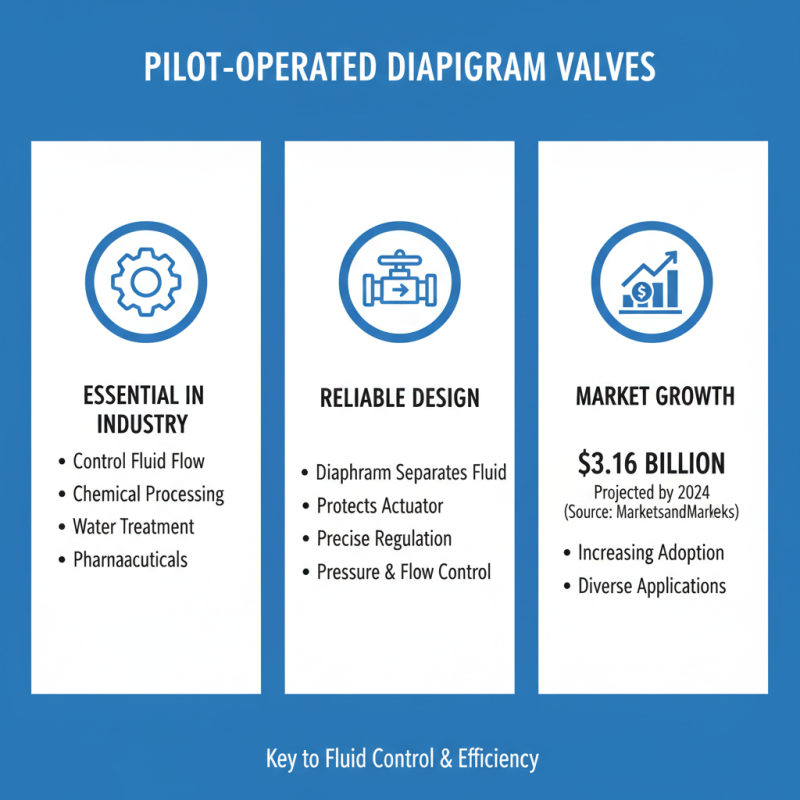

Pilot operated diaphragm valves are essential in various industries for controlling fluid flow. Their design features a diaphragm that separates the fluid from the actuator, ensuring reliable operation. This type of valve offers precise regulation of flow and pressure. According to a report by MarketsandMarkets, the market for diaphragm valves is projected to reach $3.16 billion by 2024, reflecting their increasing importance in diverse applications.

When selecting these valves, it’s crucial to understand key specifications like pressure range, temperature limits, and materials. A valve that operates efficiently at high pressure may not be suitable for low-pressure applications. Consider the fluid's properties; corrosive or abrasive fluids might require specialized materials to ensure longevity.

Tips: Always assess the installation environment. Valves exposed to extreme temperatures or vibrations may require extra attention. Regular maintenance is also vital for performance, as diaphragm wear can be hard to detect.

Overall, while these valves are robust, they are not infallible. Misapplications can lead to failures. For instance, using a diaphragm valve inappropriately in high-viscosity fluids could cause sluggish operation or even complete failure. Understanding the basics can guide you in making the right choice. Preparing for potential issues will save time and resources in the long run.

Choosing the right pilot-operated diaphragm valve begins with identifying key application requirements. Understanding these needs can significantly influence performance and reliability. For instance, a recent industry report highlights that over 30% of valve failures stem from incorrect selection. This emphasizes the need for careful consideration.

Operating conditions are critical. Factors such as pressure, temperature, and fluid type must be evaluated. According to a survey from Valves and Actuators Journal, more than 40% of users experience issues when these factors are overlooked. It’s essential to check compatibility. Incompatible materials may lead to leaks or failures.

Another factor is the flow rate. Selecting a valve that accommodates the required flow can prevent system disruptions. Flow capacity might be underestimated. A miscalculation here can lead to inefficiency and increased costs. Additionally, consider maintenance needs and accessibility. A valve requiring frequent servicing can create downtime, impacting productivity. Careful reflection on these criteria is vital for ensuring a successful selection process in your projects.

This chart shows the key application requirements for selecting a pilot operated diaphragm valve, highlighting the importance level of each factor. The factors include pressure rating, temperature range, fluid type, size, and control method, which are crucial in making the right choice for specific applications.

Choosing the right materials for a pilot operated diaphragm valve is crucial for process efficiency. Each fluid has unique properties. This affects how materials interact. Compatibility is essential to prevent failure. Common materials include rubber, plastic, and metals. However, not all materials withstand harsh environments.

When considering rubber, think about its temperature range. Some rubbers degrade quickly under heat. Others may not hold up against chemicals.

Plastic valves can resist corrosion but might be less durable overall. Metals have strengths. However, they can corrode without proper treatment. Evaluating the process fluids is just as important. Knowing the fluid's temperature, pressure, and chemical composition helps narrow down material options.

Compatibility issues can lead to costly downtime. It’s worth testing materials before final decisions. Some users overlook small details. A minor chemical reaction could result in big problems later. Always have a plan for unexpected failures. Keep an eye on valve performance post-installation. Regular checks can save time and money.

When choosing a pilot operated diaphragm valve, pressure and temperature ratings are crucial. These ratings determine the valve's ability to operate effectively. Operating outside specified limits can lead to failures. Always check the manufacturer's data sheets. A common oversight is assuming all valves can handle high pressures. This is not the case.

Consider the application requirements. High temperatures may require special materials. Not all diaphragm valves can withstand extreme heat. Inspect materials carefully, especially elastomers used in seals. They degrade quickly if overheated. A proper assessment of the environment is important.

Another aspect is fluid type. Some media can corrode materials, affecting performance. Be mindful of this when selecting your valve. Discuss your needs with experienced professionals. Sometimes, small details can lead to big issues later. Testing and feedback are essential to ensure smooth operations.

When selecting a pilot operated diaphragm valve, reliability and cost efficiency should be top priorities. Different brands offer varied performance levels. Understanding these variations can help in making an informed choice. Look for products that have a good track record in your specific application. Often, cheaper valves may save costs initially, but they can become expensive over time due to maintenance issues.

Consider the materials used in construction. Corrosive environments often require robust materials that can withstand degradation. This choice impacts both reliability and lifespan. Don't overlook the importance of customer reviews. They provide real-world insights into performance and reliability. Some users might report failure or poor service, which could guide your decision.

**Tips**: Always request samples or demonstrations before purchasing. Comparing specifications can be tricky without firsthand experience. Also, consult with engineers who possess real experience. Their insights can reveal nuances not found in product catalogs. Investing time upfront can help avoid costly mistakes later.

| Model | Size | Pressure Rating (psi) | Material | Cost ($) | Warranty (Years) | Reliability Rating (1-5) |

|---|---|---|---|---|---|---|

| Model A | 1" | 150 | PVC | 120 | 2 | 4 |

| Model B | 2" | 200 | Stainless Steel | 250 | 3 | 5 |

| Model C | 1.5" | 300 | Brass | 180 | 1 | 3 |

| Model D | 3" | 250 | Polypropylene | 300 | 5 | 4 |