Leave Your Message

In the dynamic landscape of industrial operations, selecting the appropriate Vacuum Relief Valve is critical to ensure efficiency and safety in systems dedicated to handling liquids and gases. According to a report by ResearchAndMarkets, the global vacuum valve market is projected to reach $5.9 billion by 2026, with a significant emphasis on the increasing demand for enhanced safety measures in various sectors such as chemical processing and pharmaceuticals. A Vacuum Relief Valve plays a vital role in maintaining atmospheric pressure, preventing vacuum conditions that could lead to system failures or hazards. With numerous options available, understanding the specific requirements of your application is essential.

This blog will delve into key considerations and reasons for choosing the right Vacuum Relief Valve to meet the unique demands of your industrial needs effectively.

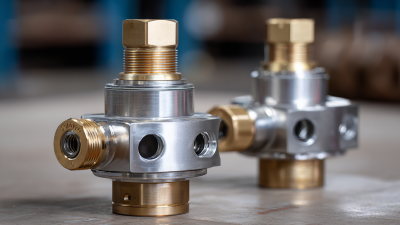

Vacuum relief valves play a crucial role in maintaining safety and efficiency in various industrial applications. These valves prevent the formation of a vacuum that can lead to structural damage or malfunction of equipment. By allowing air to enter the system when the pressure drops below a certain level, they ensure optimal performance and protect sensitive machinery. Neglecting to install appropriate vacuum relief valves can result in costly repairs and unplanned downtime.

When selecting the right vacuum relief valve, consider the specific requirements of your application. Factors such as operating pressure, temperature, and the type of materials being handled are essential. Always consult with a manufacturer or a specialist to determine the correct valve size and type that aligns with your system's demands.

**Tip**: Regular maintenance of vacuum relief valves is vital. Schedule periodic inspections to check for blockages or wear and replace any faulty components immediately to prevent malfunction.

**Tip**: It's essential to understand the response pressure of the valve. Choose a valve that opens at the correct pressure level to ensure that it activates quickly and effectively during a vacuum event. This can significantly enhance the safety and reliability of your operation.

| Attribute | Description | Importance |

|---|---|---|

| Diameter | The size of the valve opening necessary for your system. | Critical for ensuring proper throughput and preventing overpressure. |

| Material | The type of material used in the valve construction (e.g., stainless steel, aluminum). | Affects durability, resistance to corrosion, and compatibility with substances. |

| Pressure Rating | The maximum pressure the valve can withstand. | Essential for safety and operational reliability. |

| Temperature Range | The range of temperatures the valve can maintain its functionality. | Important for applications involving extreme conditions. |

| Flow Rate | Measured flow capacity of the valve. | Determines efficiency and performance of your system. |

| Certification | Industry-specific certifications (e.g., ASME, CE). | Ensures compliance with safety and operational standards. |

When selecting a vacuum relief valve for industrial applications, several key factors need to be considered to ensure optimal performance and safety. One of the primary concerns is the operating conditions of your process, including the range of vacuum levels and the potential presence of corrosive substances. For instance, the CVD and CVI vacuum furnaces market is poised for substantial growth, projected to reach USD 170.05 million by 2034, which highlights the increasing necessity for efficient vacuum systems across various industries. It's essential to choose a vacuum relief valve that can withstand these conditions to prevent system failures.

Another critical factor is the energy efficiency of the chosen equipment. With consumer trends indicating that 73% of buyers have opted out of energy-efficient vacuum cleaners, the importance of sustainability in industrial applications cannot be overlooked. Innovations like the ammonia vacuum thermal stripping process have showcased how optimizing efficiency through technology can lead to significant energy savings. Therefore, while selecting a vacuum relief valve, evaluating its energy consumption and sustainability profile is crucial to align with contemporary environmental standards and operational costs.

When selecting a vacuum relief valve for industrial applications, understanding the various types and their respective advantages and disadvantages is crucial. One common type is the spring-loaded valve, known for its reliability and precise pressure control. These valves excel in applications requiring a tight seal, minimizing the risk of vacuum loss. However, they can be sensitive to particulate matter, which may lead to malfunction if not properly maintained.

Another type is the weighted or pendulum valve, which operates based on gravity. These valves are simple and durable, making them suitable for environments with high dust or debris levels. They can handle larger quantities of air, effectively stabilizing pressure in larger systems. Nonetheless, their design can sometimes lead to slower response times in dynamic systems, which may not be ideal for all applications.

Finally, consider the electronic vacuum relief valves, which offer advanced control and monitoring capabilities. By utilizing sensors and automation, these valves can quickly adapt to changing pressures and enhance system efficiency. However, they come at a higher initial cost and require a reliable power source for operation, which can be a drawback in some industrial settings. Evaluating these pros and cons will aid in making an informed choice tailored to your specific needs.

When selecting a vacuum relief valve for industrial applications, it is essential to consider the prevailing industry standards and regulations that can significantly influence your choice. Organizations such as the American Society of Mechanical Engineers (ASME) and the National Fire Protection Association (NFPA) provide guidelines that ensure safety and operational efficiency. According to a 2022 report from the International Society of Automation, approximately 20% of industrial valve failures are attributed to non-compliance with these industry standards, underscoring the necessity of adhering to regulations during the selection process.

The performance and reliability of vacuum relief valves are also shaped by various industry certifications. For instance, valves that hold ISO 9001 certification tend to demonstrate enhanced reliability and quality assurance. In sectors like chemical processing and petroleum, where safety and environmental regulations are stringent, the use of compliant vacuum relief valves can mitigate risks significantly. A survey by the American Petroleum Institute revealed that the use of certified valves has led to a 30% reduction in safety incidents in the last decade. As industries like Enserve Engineering Services mark milestones such as 30 years in operation, their commitment to providing solutions that meet these high standards is vital in promoting safety and reliability in industrial processes.

In various industries, the implementation of vacuum relief valves has proven essential for maintaining operational safety and efficiency. One notable case study involves a chemical processing plant that faced frequent pressure fluctuations, leading to potential hazards in their storage tanks. By integrating a reliable vacuum relief valve, the facility successfully mitigated risks associated with tank implosions. The valve allowed for the safe venting of excess vacuum pressure, ensuring that the internal pressure remained stable during operations, thereby enhancing overall safety standards.

Another compelling example can be found in the food and beverage sector, where a bottling company struggled with product spoilage due to improper vacuum levels in their tanks. After assessing their needs, they opted for a vacuum relief valve designed specifically for sanitary applications. The implementation of this valve not only safeguarded product integrity by maintaining optimal vacuum conditions but also streamlined their processing time, ultimately increasing production efficiency. These case studies emphasize the critical role that appropriate vacuum relief valves play in protecting both industrial equipment and the quality of products across various sectors.