Leave Your Message

In the realm of plumbing and water heating systems, the Geyser Pressure Valve plays a crucial role in ensuring safe and efficient performance. According to a report by the American Society of Mechanical Engineers, nearly 70% of residential water heating issues stem from improper valve maintenance or selection. Choosing the right Geyser Pressure Valve not only enhances the durability of your water heater but also protects your home from potential hazards like overheating and pressure build-up.

Industry expert Dr. John McMillan emphasizes the importance of understanding technical specifications and operational requirements when selecting a Geyser Pressure Valve. He states, “An appropriate choice of pressure valve is essential for optimal geyser performance and longevity.” This statement underscores the necessity for homeowners and professionals alike to prioritize quality and compatibility when investing in these crucial components.

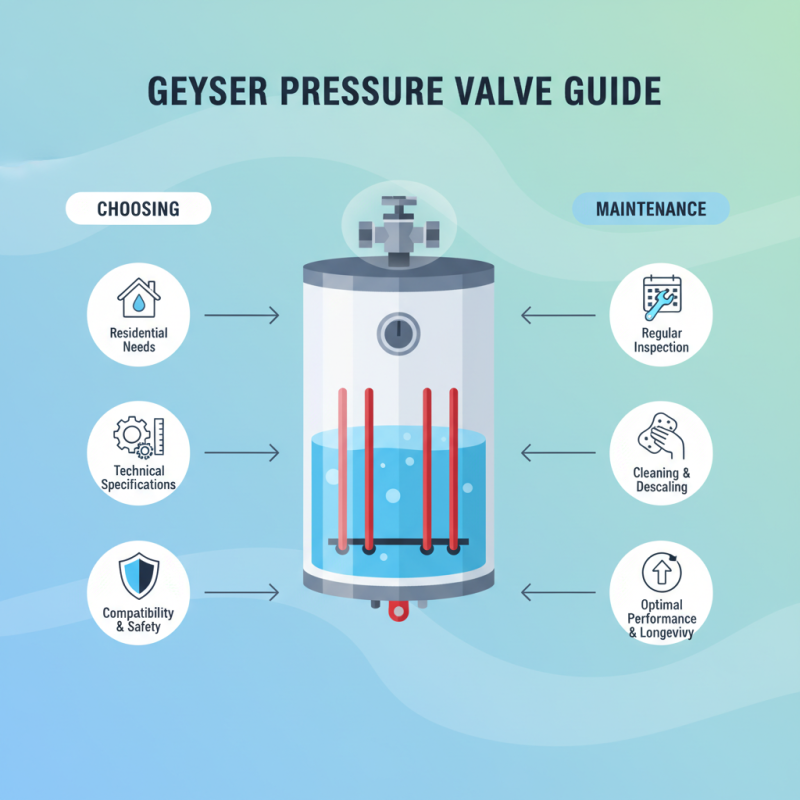

Regular maintenance and proper selection based on individual needs can significantly extend the life of your geyser system. By delving into the guidelines outlined in this article, readers will be equipped with the knowledge to make informed decisions regarding their Geyser Pressure Valve, ensuring both efficiency and safety for years to come.

Geyser pressure valves, often underestimated, play a crucial role in ensuring the safe and efficient operation of water heating systems. These valves are designed to regulate and maintain optimal pressure levels within geysers, preventing hazardous situations that can arise from excessive pressure buildup. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper pressure regulation can lead to significant safety risks, including potential explosions and thermal fatigue in the heater's structure.

The importance of these valves extends beyond safety. An efficient pressure valve can improve the longevity of a geyser by minimizing wear and tear from fluctuating pressure levels, ultimately reducing maintenance costs. A study by the International Plumbing and Mechanical Officials (IAPMO) indicated that regular maintenance of pressure valves can enhance energy efficiency by up to 15%, offering both economic and environmental benefits. Understanding the function and importance of geyser pressure valves is essential for any homeowner or facility manager aiming for optimal performance and safety in their hot water systems.

When selecting a geyser pressure valve, several key factors must be considered to ensure optimal performance and safety. First and foremost, it is essential to assess the pressure rating of the valve, which should match or exceed the geyser’s specifications. This alignment helps prevent leaks and potential damage to the unit. Additionally, it is crucial to choose a valve made from durable materials, such as brass or high-quality plastic, which can withstand high temperatures and corrosive water conditions.

Another vital aspect to consider is the size and compatibility of the valve with the existing geyser setup. Proper sizing not only ensures seamless installation but also maintains efficient water flow. Furthermore, checking for certifications and standards compliance can provide peace of mind regarding the quality and safety of the valve. Lastly, consider the maintenance requirements of the valve. Regular inspection and servicing will help prolong its lifespan and maintain optimal performance, making it easier to enjoy hot water without unexpected interruptions.

Installing a geyser pressure valve is crucial for ensuring the safe operation of your water heater. The first step is to gather the necessary tools, including a wrench, pliers, and a bucket to catch any residual water. Begin by turning off the power supply and closing the water supply valve to prevent any accidents. Next, locate the pressure relief valve on your geyser, which is typically found on the side or the top of the unit.

Once the power and water supply are off, use a wrench to carefully remove the old pressure valve. Be ready for some water spillage, so having a bucket handy is essential. Clean the threaded area before installing the new valve to ensure a secure fit. Apply plumber’s tape to the threads of the new valve to prevent leaks, then screw it into place firmly but not overly tight. After everything is secured, restore the water supply and power, and check for proper functioning by monitoring the pressure gauge and listening for any unusual noises. Regular checks and maintenance can help extend the longevity of your geyser pressure valve and improve overall system performance.

Routine maintenance of your geyser pressure valve is essential to ensure optimal performance and extend its lifespan. Regular inspections can help identify early signs of wear or damage, preventing costly emergencies. According to a report by the American Society of Plumbing Engineers, regular maintenance can reduce the chances of valve failure by up to 30%, which can lead to leaks and other plumbing issues.

One key maintenance tip includes checking the valve’s pressure settings. The ideal pressure should typically be between 50-60 psi. If the pressure exceeds this range, it may indicate that the valve is malfunctioning, which could put your geyser at risk. Additionally, it's crucial to flush the valve regularly to remove any sediment buildup. The National Association of Home Builders suggests that flushing your geyser and its components at least once a year can improve efficiency by 5-10%, which directly correlates to energy savings and reduced utility bills.

Ensuring the safety release valve is functioning properly is another critical aspect of maintenance. Performing a simple test every six months can prevent dangerous pressure build-up, safeguarding your home. Recommendations from the Plumbing-Heating-Cooling Contractors Association stress that prioritizing these maintenance tasks can significantly enhance the longevity and reliability of your pressure valve.

| Dimension | Details |

|---|---|

| Type of Valve | Pressure Relief Valve |

| Material | Brass or Stainless Steel |

| Pressure Rating | 150 psi to 300 psi |

| Temperature Rating | Up to 200°F (93°C) |

| Maintenance Frequency | Every 6 Months |

| Common Issues | Leaking, Sticking Mechanism |

| Signs of Wear | Discoloration, Rust, Corrosion |

| Maintenance Tips | Regular Cleaning, Check Seals |

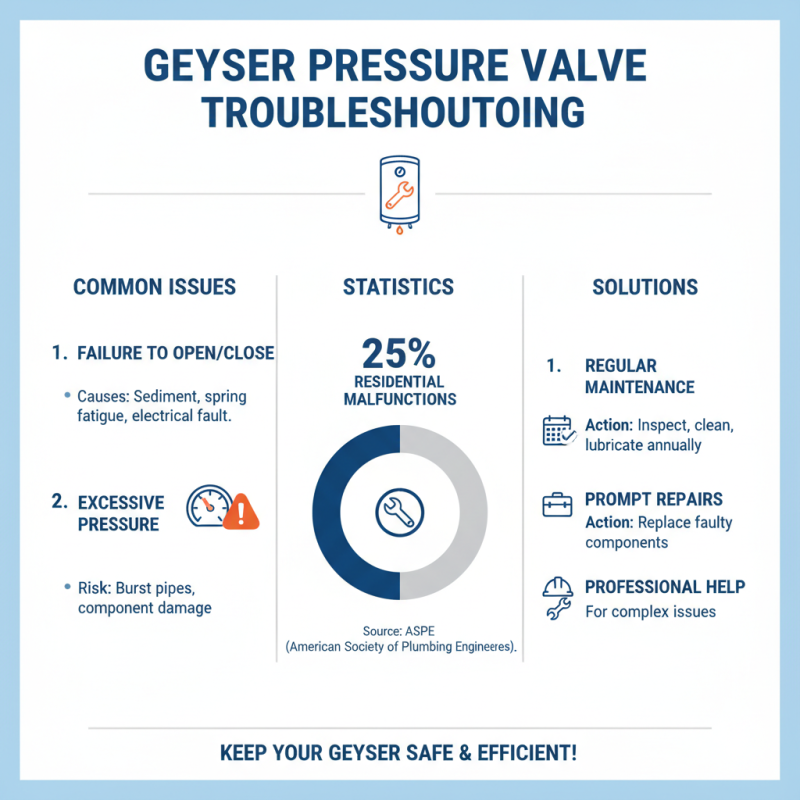

Geyser pressure valves are crucial components in maintaining the safe operation of geysers, yet they can encounter several common issues that require troubleshooting. One prevalent problem is the valve's failure to open or close properly, which can lead to excessive pressure buildup. According to the American Society of Plumbing Engineers, approximately 25% of residential geyser malfunctions are linked to valve issues, underscoring the importance of regular maintenance and prompt repairs.

Another common issue is the accumulation of sediment, which can obstruct the valve mechanism, impairing its function. A study published by the Journal of Water Management indicates that neglecting sediment buildup can reduce the efficiency of the geyser system by up to 15%. To mitigate these risks, regular inspections, cleaning, and timely replacement of worn-out valves are essential. Proper installation techniques, as recommended by the Plumbing-Heating-Cooling Contractors Association, can also prevent issues before they start.