Leave Your Message

In industries where flammable materials are present, the importance of safety cannot be overstated. A deflagration arrester plays a crucial role in preventing explosions. According to a recent report from the International Safety Standards Organization, over 30% of industrial accidents related to combustible dust are linked to inadequate safety measures. This stresses the need for proper equipment in industrial settings.

Dr. John Anderson, a leading expert in explosion prevention technology, states, “Choosing the right deflagration arrester can save lives and protect assets.” This highlights the responsibility companies have in selecting the appropriate device. Factors such as material compatibility, installation requirements, and maintenance efficiency should be considered meticulously. A minor oversight here can lead to catastrophic events.

Yet, many organizations underestimate these details. The desire for cost-saving sometimes overshadows the need for thorough research. Understanding the nuances of a deflagration arrester can lead to better safety management. Engaging with experts and utilizing data-driven decisions is essential for making informed choices. It’s an opportunity for improvement in a field that constantly evolves.

Deflagration arresters play a critical role in maintaining safety in various industrial processes. They function by slowing down or stopping the propagation of deflagration—a rapid, but subsonic combustion wave through a gas mixture. When a fire or explosion occurs, these devices can prevent catastrophic damage by controlling the flames and pressures involved. Understanding how these systems work is vital for effective application.

When choosing a deflagration arrester, consider the design features. These devices typically utilize flame arresting elements, which are crucial for resistance against extreme pressures. Selecting the wrong design may compromise safety. Often, users overlook this detail. Make sure to evaluate environmental conditions. Temperature and humidity can impact performance.

Quality and maintenance play essential roles too. Check the materials used in construction. They must withstand harsh chemicals and temperatures. Poor quality may lead to premature failure. Lastly, seek guidance from industry experts. Their experience highlights potential pitfalls and offers valuable insights. A good choice reflects thorough research and careful consideration.

When selecting a deflagration arrester, several key factors come into play. Understanding these elements is crucial for ensuring safety and efficiency. One important aspect is the application environment. Know where the arrester will be installed. Different settings may require specific features. For example, high humidity areas might need corrosion-resistant materials.

Capacity is another vital factor. Assess the maximum volume of gas that will pass through the arrester. This determines its effectiveness in preventing deflagration. If the arrester can't handle the flow, dangerous situations can arise. Consider the flow rates and choose accordingly. Adapting your selection to your system requirements is essential.

Installation requirements should also be considered. Sometimes, a standard arrester may not fit your system's specific configurations. Check all relevant dimensions. The device must integrate seamlessly into your setup. Ignoring installation concerns could lead to failures. Each factor can dramatically influence performance. An arrester must not only function well but also fit correctly to work safely.

When selecting a deflagration arrester, the material and design are critical for achieving maximum safety. It's crucial to choose materials that can withstand high temperatures and pressures. Stainless steel is popular due to its durability. However, some cheaper alternatives may not provide adequate protection. These could compromise safety, leading to potential hazards.

The design should ensure efficient gas flow while minimizing pressure build-up. A well-designed arrester can allow for safe venting during deflagration events. Simpler designs often risk trapping heat or pressure, increasing the chance of failure. Regularly checking for wear and tear is essential, as even minor flaws can lead to significant issues. Remember, what seems cheap now could turn into a costly mistake later. Choose wisely.

When selecting a deflagration arrester, compliance with industry standards and regulations is crucial. Many industries must adhere to safety protocols set by organizations like NFPA and API. These standards provide guidelines on maintaining safe operating conditions. Non-compliance could lead to accidents. According to recent reports, nearly 30% of industrial incidents stem from improper equipment selection.

Tip: Always check the arrester's certification. Ensure it meets relevant standards. Certification confirms that the device has been rigorously tested for safety and efficiency.

Another key consideration is the specific application of the arrester. Different environments present unique challenges. For example, factors such as temperature and pressure can influence performance. Using equipment not suited for your particular conditions can lead to system failures.

Tip: Consult with safety experts. They can provide insights tailored to your situation. Their experience can help you avoid common pitfalls while selecting the right equipment.

| Tip | Description | Regulatory Standards |

|---|---|---|

| 1. Understand Material Compatibility | Ensure the arrester is made from materials that can withstand the specific chemicals involved in your process. | NFPA 68, ASHRAE 15 |

| 2. Evaluate Pressure Drop | Select an arrester that minimizes pressure drop while maintaining effectiveness in preventing deflagrations. | ISO 6184-1, EN 14460 |

| 3. Confirm Proper Sizing | Size the arrester according to the system’s maximum expected flow rate to ensure proper function. | NFPA 68 |

| 4. Ensure Certification Compliance | Check for certifications from recognized bodies to confirm compliance with safety standards. | ATEX, UL Standards |

| 5. Assess Maintenance Requirements | Consider the maintenance frequency and ease of access for ongoing inspections and replacements. | OSHA 1910.106 |

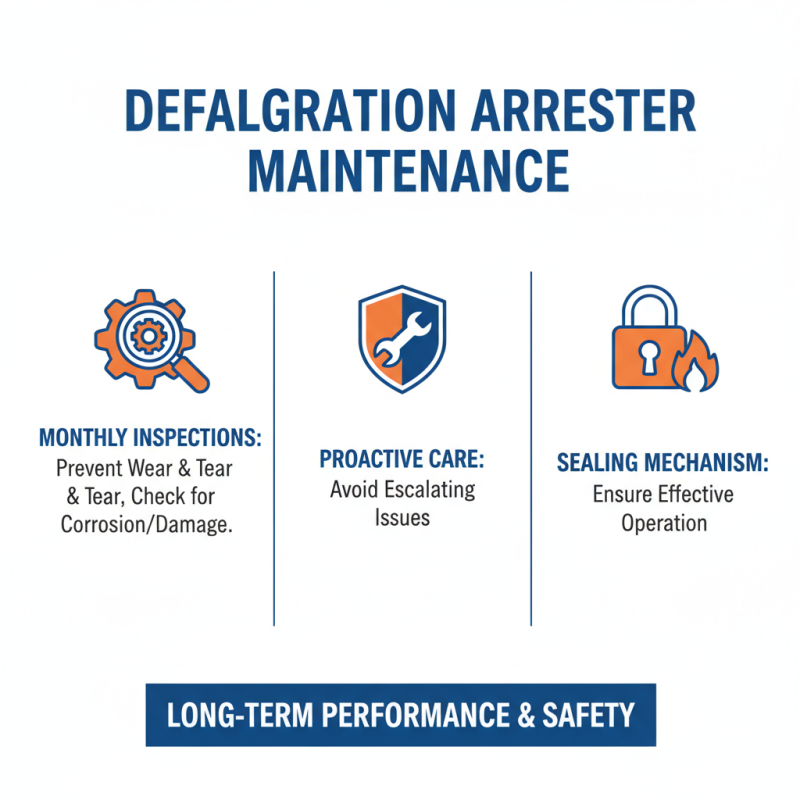

Maintaining a deflagration arrester is crucial for its long-term performance. Regular inspections help spot wear and tear. Look for corrosion or physical damage. A thorough check once a month is often recommended. This proactive approach can prevent serious issues down the line. Keep an eye on the sealing mechanism too, as it is vital for effective operation.

Cleaning is another key aspect. Dust and debris can accumulate over time. This buildup can restrict airflow, making the device less efficient. Use appropriate tools to ensure all parts are clean. A checklist can help you ensure you don’t forget any area. It’s easy to overlook small sections, but they matter.

Finally, consider the environment where the arrester operates. Harsh conditions may require more frequent maintenance. If the system is located in a dusty or corrosive area, adjust your schedule accordingly. Ignoring environmental factors can lead to unexpected failures. Reflect on past experiences and adapt your approach based on what has occurred before. Maintenance is not just about fixing problems; it’s about preventing them.